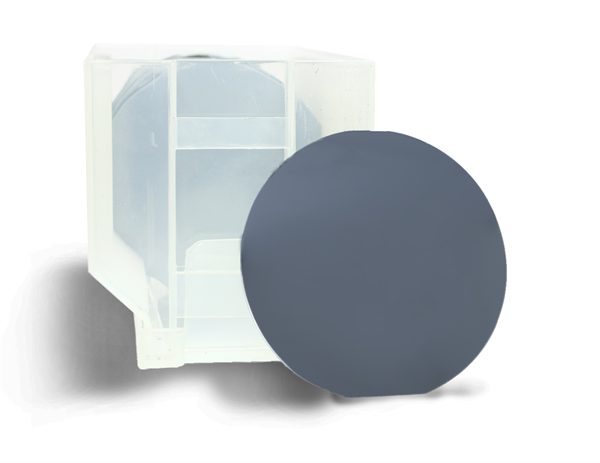

Substrate-ka SiC P-nooca 4H/6H-P 3C-N 4inch leh dhumucdiisuna tahay 350um heerka wax soo saarka

4inch substrate SiC P-nooca 4H/6H-P 3C-N miiska cabirka

4 dhexroorka inch SiliconSubstrate-ka Carbide (SiC). Tilmaamid

| Darajo | Wax soo saarka MPD eber Darajada (Z Darajo) | Wax soo saarka caadiga ah Darajada (P Darajo) | Dummy Fasalka (D Darajo) | ||

| Dhexroorka | 99.5 mm ~ 100.0 mm | ||||

| Dhumucda | 350 μm ± 25 μm | ||||

| Hanuuninta Wafer | dhidibka ka baxsan: 2.0°-4.0° dhanka [1120] ± 0.5° loogu talagalay 4H/6H-P, On dhidibka:〈111〉± 0.5° ee 3C-N | ||||

| Cufnaanta Dheef-yar | 0 cm-2 | ||||

| iska caabin | p-nooca 4H/6H-P | ≤0.1 Ωꞏcm | ≤0.3 Ωꞏcm | ||

| n-nooca 3C-N | ≤0.8 mΩꞏcm | ≤1 m Ωꞏcm | |||

| Hanuuninta Flat Primary | 4H/6H-P | - {1010} ± 5.0° | |||

| 3C-N | - {110} ± 5.0° | ||||

| Dhererka Guriga aasaasiga ah | 32.5 mm ± 2.0 mm | ||||

| Dhererka Guriga Sare | 18.0 mm ± 2.0 mm | ||||

| Hanuuninta Guriga Sare | Silicon weji kor ah: 90° CW. ka yimid dabaqa Prime±5.0° | ||||

| Ka saarida gees | 3 mm | 6 mm | |||

| LTV/TTV/Bow/Warp | ≤2.5 μm/≤5 μm/≤15 μm/≤30 μm | ≤10 μm/≤15 μm/≤25 μm/≤40 μm | |||

| Qalafsanaan | Polish Ra≤1 nm | ||||

| CMP Ra≤0.2 nm | Ra≤0.5 nm | ||||

| Dildilaaca Cidhifyada Iftiinka Xoogan Sare | Midna | Dhererka isugeynta ≤ 10 mm, hal dherer≤2 mm | |||

| Taarikada Hex By Iftiin Xoogan Sare | Aagga wadarta ≤0.05% | Aagga isugeynta ≤0.1% | |||

| Meelo Badan Oo Iftiin Xoogan Sare leh | Midna | Aagga isugeynta≤3% | |||

| Kaarboon Muuqaal ah | Aagga wadarta ≤0.05% | Aagga isugeynta ≤3% | |||

| Dusha sare ee Silikoon xoqida Iftiinka xoogga sare | Midna | Dhererka isugeynta≤1× dhexroorka wafer | |||

| Chips-ka Cidhifka Sare ee Iftiinka Xooga | Midna lama oggola ≥0.2mm ballac iyo qoto dheer | 5 waa la ogol yahay, ≤1 mm midkiiba | |||

| Wasakhaynta Silikoonka Dusha Sare ee Xooggiisa | Midna | ||||

| Baakadaha | Cassette-wafer-badan ama weel wafer oo kali ah | ||||

Xusuusin:

※ Xadka cilladuhu waxay khuseeyaan dhammaan dusha sare ee waferka marka laga reebo aagga ka saarista cidhifka. # xagashada waa in lagu fiiriyaa wejiga Si kaliya.

Nooca P-nooca 4H/6H-P 3C-N 4-inch SiC substrate oo leh dhumucdiisuna tahay 350 μm ayaa si ballaaran loogu dabaqay soosaarka qalabka korantada ee horumarsan. Iyada oo leh koronto kuleyl heer sare ah, koronto jabin sare leh, iyo iska caabin adag oo deegaanka aadka u daran, substrate-kani wuxuu ku habboon yahay korantada waxqabadka sare leh sida furayaasha korantada sare, rogayaasha, iyo aaladaha RF. Substrate-ka-soo-saarka waxaa loo isticmaalaa wax soo saar ballaaran, hubinta la isku halayn karo, waxqabadka qalabka saxda ah, kaas oo muhiim u ah korantada elektiroonigga ah iyo codsiyada soo noqnoqda. Dummy-fasalka, dhinaca kale, waxaa inta badan loo isticmaalaa habaynta habraaca, tijaabinta qalabka, iyo horumarinta prototype, ka caawinta ilaalinta tayada tayada iyo habka joogtaynta wax soo saarka semiconductor.

Tilmaamaha Faa'iidooyinka N-nooca SiC ee ka kooban substrate-ka waxaa ka mid ah

- Dhaqdhaqaaqa Kuleylka Sare: Kuleyl wax ku ool ah oo kuleyl ah ayaa ka dhigaya substrate ku habboon codsiyada heerkulka sare iyo awoodda sare.

- Korontada Burburka Sare: Waxay taageertaa hawlgalka korantada sare, hubinta isku halaynta korantada korantada iyo aaladaha RF.

- Iska caabinta Degaanada Adag: Ku waara xaaladaha aadka u daran sida heerkulka sare iyo deegaanka daxalka, hubinta waxqabadka muddada dheer.

- Wax-soo-saarka- Saxnaanta Darajada: Waxay hubisaa tayada sare iyo waxqabadka lagu kalsoonaan karo ee wax soo saarka ballaaran, oo ku habboon awoodda sare iyo codsiyada RF.

- Dummy-Fasalka Imtixaanka: Waxay sahlaysa habaynta saxda ah ee habka saxda ah, tijaabinta qalabka, iyo prototyping iyada oo aan wax u dhimayn waferrada heerka-soo-saarka.

Guud ahaan, nooca P-nooca 4H/6H-P 3C-N 4-inch SiC substrate leh dhumucdiisuna tahay 350 μm waxay bixisaa faa'iidooyin la taaban karo oo loogu talagalay codsiyada elektarooniga ah ee waxqabadka sarreeya. Heerkulkeeda sare ee kuleylka iyo korantada burburka ayaa ka dhigaysa mid ku habboon jawiga tamarta sare iyo heerkulka sare, halka iska caabbinta xaaladaha adag ay hubiso adkeysiga iyo isku halaynta. Substrate-ka-soo-saarka ayaa hubiya waxqabadka saxda ah ee joogtada ah ee wax-soo-saarka baaxadda leh ee korantada elektiroonigga ah iyo aaladaha RF. Dhanka kale, substrate-ka-dulmiga ayaa lama huraan u ah habaynta habraaca, tijaabinta qalabka, iyo samaynta, taageeridda xakamaynta tayada iyo joogtaynta wax-soo-saarka semiconductor. Tilmaamahani waxay ka dhigaan substrate-yada SiC mid aad ugu wanagsan codsiyada horumarsan.

Jaantus faahfaahsan