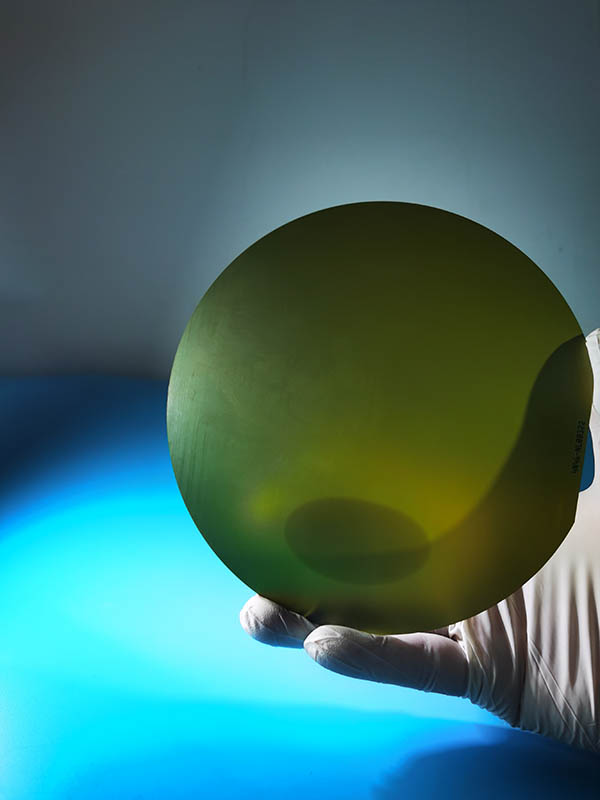

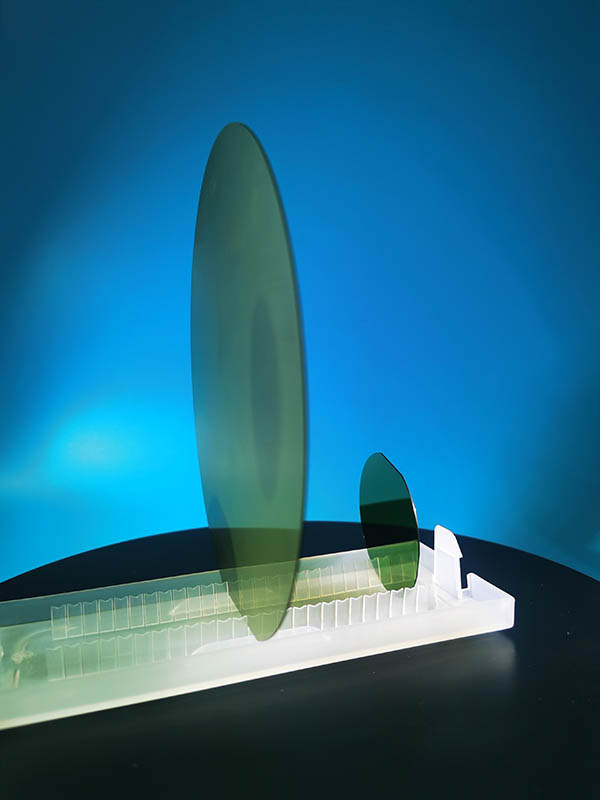

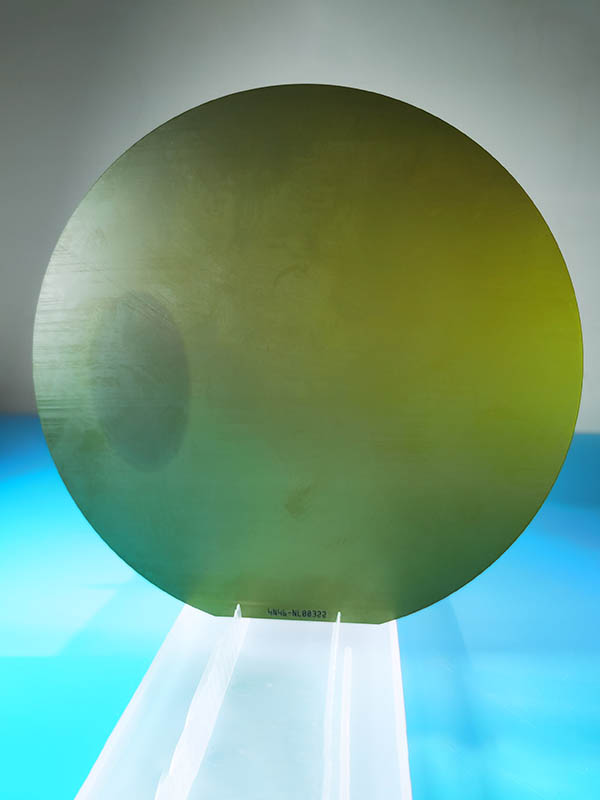

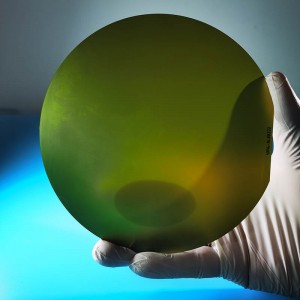

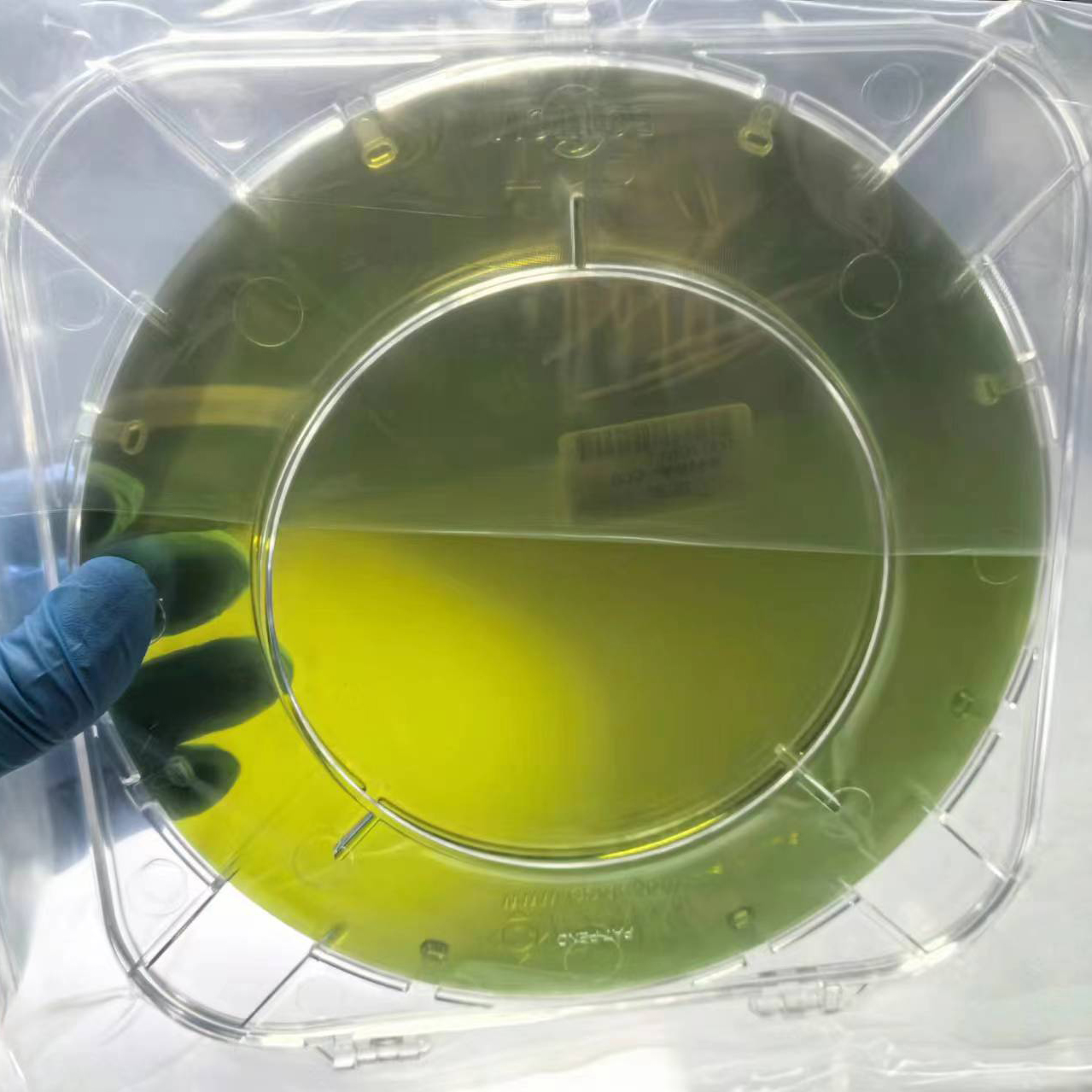

8Inch 200mm 4H-N SiC Wafer Conductive naasaha darajo cilmi baaris

Iyada oo ay ugu wacan tahay sifooyinkeeda gaarka ah ee jirka iyo elektiroonigga ah, 200mm SiC wafer semiconductor wafer waxaa loo isticmaalaa in lagu abuuro wax qabad sare, heerkul sare, shucaac u adkaysta, iyo aaladaha elektiroonigga ah ee soo noqnoqda. 8inch SiC substrate qiimaha ayaa si tartiib tartiib ah hoos ugu dhacaya marka tignoolajiyada ay noqoto mid horumarsan oo baahidu korodho. Horumarinta tignoolajiyada dhawayd waxay horseed u tahay wax soo saarka miisaanka wax soo saarka ee 200mm wafers SiC. Faa'iidooyinka ugu muhiimsan ee qalabka semiconductor ee SiC wafer marka la barbardhigo Si iyo GaAs wafers: Awoodda beerta korantada ee 4H-SiC inta lagu jiro burburka qulqulka ayaa ka badan amar ka sarreeya qiyamka u dhigma ee Si iyo GaAs. Tani waxay keenaysaa hoos u dhac weyn oo ku yimaadda iska caabbinta gobolka-Ron. Iska caabbinta hoose ee gobolka, oo ay weheliso cufnaanta sare ee hadda jirta iyo kulaylka kuleylka, waxay u oggolaaneysaa isticmaalka dhimashada aadka u yar ee qalabka korontada. Heerarka kulaylka sare ee SiC waxay yaraynaysaa caabbinta kulaylka ee chip. Qalabka elektiroonigga ah ee aaladaha ku saleysan waferrada SiC waa kuwo aad u xasilloon waqti ka dib iyo heerkul deggan, taas oo hubinaysa kalsoonida sare ee alaabada. Silicon carbide aad bay ugu adkaysanaysaa shucaaca adag, kaas oo aan hoos u dhigin sifooyinka elektarooniga ah ee chip-ka. Heerkulka sare ee xaddidaadda shaqada ee crystal (in ka badan 6000C) waxay kuu ogolaaneysaa inaad abuurto qalab aad loogu kalsoon yahay xaaladaha adag ee hawlgalka iyo codsiyada gaarka ah. Waqtigan xaadirka ah, waxaan ku siin karnaa dufcad yar oo 200mmSiC wafers si joogto ah oo joogto ah waxaanan ku yeelan karnaa xoogaa bakhaar ah.

Tilmaamid

| Tirada | Shayga | Unug | Wax soo saar | Cilmi baaris | nacasnimo |

| 1. Halbeegyada | |||||

| 1.1 | nooca badan | -- | 4H | 4H | 4H |

| 1.2 | jihaynta dusha sare | ° | <11-20>4±0.5 | <11-20>4±0.5 | <11-20>4±0.5 |

| 2. Qalabka korantada | |||||

| 2.1 | dopanant | -- | n-nooca Nitrogen | n-nooca Nitrogen | n-nooca Nitrogen |

| 2.2 | iska caabin | ah ·cm | 0.015-0.025 | 0.01-0.03 | NA |

| 3. Mechanical parameter | |||||

| 3.1 | dhexroorka | mm | 200±0.2 | 200±0.2 | 200±0.2 |

| 3.2 | dhumucdiisuna | μm | 500± 25 | 500± 25 | 500± 25 |

| 3.3 | Hanuuninta darajada | ° | [1- 100]±5 | [1- 100]±5 | [1- 100]±5 |

| 3.4 | Qoto dheer | mm | 1 ~ 1.5 | 1 ~ 1.5 | 1 ~ 1.5 |

| 3.5 | LTV | μm | ≤5(10mm*10mm) | ≤5(10mm*10mm) | ≤10 (10mm*10mm) |

| 3.6 | TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Qaansada | μm | -25 ~ 25 | -45-45 | -65-65 |

| 3.8 | Warp | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | AFM | nm | Ra≤0.2 | Ra≤0.2 | Ra≤0.2 |

| 4. Qaab dhismeed | |||||

| 4.1 | cufnaanta micropipe | ee/cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | maadada birta ah | atamka/cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | ee/cm2 | ≤500 | ≤1000 | NA |

| 4.4 | BPD | ee/cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | TED | ee/cm2 | ≤7000 | ≤10000 | NA |

| 5. Tayo wanaagsan | |||||

| 5.1 | hore | -- | Si | Si | Si |

| 5.2 | dusha sare dhammayn | -- | Si-wejiga CMP | Si-wejiga CMP | Si-wejiga CMP |

| 5.3 | qayb | ea/wafer | ≤100 (xajmiga≥0.3μm) | NA | NA |

| 5.4 | xoqin | ea/wafer | ≤5, Wadarta Dhererka≤200mm | NA | NA |

| 5.5 | Cidhif chips/indents/ dildilaaca/ wasakhowga | -- | Midna | Midna | NA |

| 5.6 | Aagagga nooca badan | -- | Midna | Aagga ≤10% | Aagga ≤30% |

| 5.7 | calaamadaynta hore | -- | Midna | Midna | Midna |

| 6. Tayada dhabarka | |||||

| 6.1 | dib u dhammayn | -- | C-waji xildhibaan | C-waji xildhibaan | C-waji xildhibaan |

| 6.2 | xoqin | mm | NA | NA | NA |

| 6.3 | Cilladaha dhabarka gees chips/indents | -- | Midna | Midna | NA |

| 6.4 | Dhabar xumada | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Calaamadaynta dhabarka | -- | Darajo | Darajo | Darajo |

| 7. gees | |||||

| 7.1 | gees | -- | Chamfer | Chamfer | Chamfer |

| 8. Xidhmada | |||||

| 8.1 | baakad | -- | Epi- diyaar u ah faakuum baakad | Epi- diyaar u ah faakuum baakad | Epi- diyaar u ah faakuum baakad |

| 8.2 | baakad | -- | Multi-wafer baakad cajalad | Multi-wafer baakad cajalad | Multi-wafer baakad cajalad |

Jaantus faahfaahsan