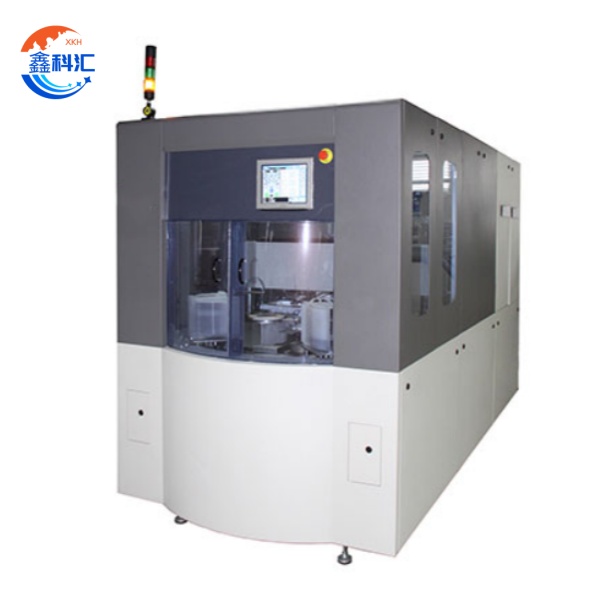

Qalabka khafiifka ah ee Wafer ee 4 inch-12 inch Sapphire/SiC/Si Wafers Processing

Mabda'a Shaqada

Habka khafiifinta waferku wuxuu u shaqeeyaa saddex marxaladood:

Shiidin qallafsan: Shaagagga dheemanka ah ( cabbirka 200-500 μm) wuxuu ka saarayaa 50-150 μm walxaha 3000-5000 rpm si degdeg ah loo yareeyo dhumucda.

Shiidin Fiican: Taayir yar oo khafiif ah (xajmiga gogosha 1-50 μm) wuxuu yareeyaa dhumucda ilaa 20-50 μm marka loo eego <1 μm/s si loo yareeyo burburka dhulka hoose.

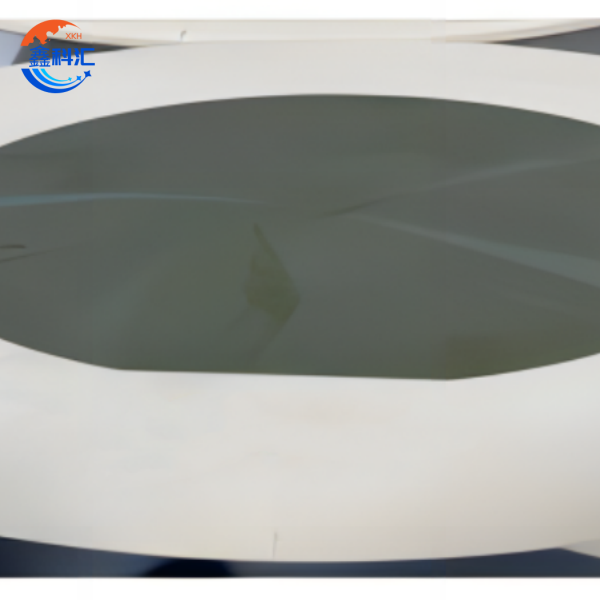

Polishing (CMP): Biyo-mareen kiimiko-farsamo ah ayaa baabi'iya burburka haraaga ah, gaaritaanka Ra <0.1 nm.

Qalab ku habboon

Silikoon (Si): Halbeegga waferrada CMOS, oo la khafiifiyay ilaa 25 μm ee isku dhafka 3D.

Silicon Carbide (SiC): Waxay u baahan tahay taayirrada dheemanka gaarka ah (80% dheemanka dheemanka) xasilloonida kuleylka.

Sapphire (Al₂O₃): La khafiifiyay ilaa 50 μm ee codsiyada UV LED.

Qaybaha Nidaamka Muhiimka ah

1. Nidaamka wax shiida

Furaha Dual-Axis: Wuxuu isku daraa shiidid qallafsan/fiicnaan leh oo hal madal ah, taasoo yaraynaysa wakhtiga wareegga 40%.

Spindle Aerostatic: 0-6000 rpm kala duwanaansho xawli ah oo leh <0.5 μm radial runout.

2. Nidaamka Maareynta Wafer

Vacuum Chuck:> 50 N xoog haynta leh ± 0.1 μm saxnaanta meelaynta.

Cududda Robotic: Waxay ku raridaa 4-12-inch wafers at 100 mm/s.

3. Nidaamka xakamaynta

Interferometry Laser: La socodka dhumucda wakhtiga-dhabta ah (xalka 0.01 μm).

Feedforward-ka AI-Driven: Wuxuu saadaaliyaa xirashada taayirrada oo si toos ah u hagaajiya cabbirrada.

4. Qaboojinta & Nadiifinta

Nadiifinta Ultrasonic: Waxay ka saartaa walxaha>0.5 μm oo leh 99.9% hufnaan.

Biyaha Deionized: Qaboojiya maraqa ilaa <5°C oo ka sarreeya jawiga.

Faa'iidooyinka Muhiimka ah

1. Saxnimada aadka u saraysa: TTV (Guud ahaan kala duwanaanshiyaha dhumucda) <0.5 μm, WTW (Kala duwanaanshaha Dhumucda Wafer dhexdeeda) <1 μm.

2. Isku-dhafka Hab-raaca Badan: Isku-dubbarididda, CMP, iyo etching balaasmaha ee hal mashiin.

3. Waafaqsanaanta Shayga:

Silikoon: Dhimista dhumucda 775 μm ilaa 25 μm.

SiC: Waxay ku guulaysataa <2 μm TTV ee codsiyada RF.

Wafers Doped: Fosfooraska-doped InP wafers oo leh <5% iska caabin ah.

4. Smart Automation: Is dhexgalka MES wuxuu yareeyaa qaladka aadanaha 70%.

5. Waxtarka Tamarta: 30% isticmaalka korantada oo hooseysa iyada oo loo marayo braking dib u soo kicinta.

Codsiyada Muhiimka ah

1. Baakaynta horumarsan

• 3D ICs: khafiifinta Waferku waxa ay sahlaysa in si toosan loo xidho chips-ga macquulka/xasuusta (tusaale, xidhmooyin HBM), gaaritaanka 10 × bandwidth sare iyo 50% hoos u dhaca isticmaalka awooda marka la barbar dhigo xalalka 2.5D. Qalabku wuxuu taageeraa isku-xidhka isku-dhafka ah iyo TSV (Iyadoo-Silicon Via) is dhexgalka, oo muhiim u ah soo-saareyaasha AI/ML ee u baahan <10 μm garoonka isku-xirnaanta. Tusaale ahaan, waferrada 12-inji ah oo la khafiifiyay ilaa 25 μm waxay u oggolaanayaan in la isku dhejiyo 8+ lakab iyadoo la ilaalinayo <1.5% bogga dagaalka, oo lagama maarmaan u ah nidaamyada LiDAR baabuurta.

• Xirmooyinka Taageerada: Iyada oo la dhimayo dhumucda wafer ilaa 30 μm, dhererka isku xidhka ayaa la soo gaabiyay 50%, iyadoo la yaraynayo daahitaanka signalka (<0.2 ps/mm) oo awood u siinaya 0.4mm chiplets aadka u khafiifka ah ee SoC-yada mobilada. Nidaamku wuxuu ka faa'iidaysanayaa algorithms-shiidida culeyska culeyska si looga hortago warpage (> 50 μm TTV control), hubinta isku halaynta codsiyada RF-sare ee soo noqnoqda.

2. Korontada Elektarooniga ah

• Modules IGBT: Khafiifinta ilaa 50 μm waxay yaraynaysaa caabbinta kulaylka ilaa <0.5°C/W, taas oo u sahlaysa 1200V SiC MOSFETs inay ku shaqeeyaan heerkulka isgoysyada 200°C. Qalabkeenu waxa uu shaqeeyaa shiidi heerar kala duwan (qaracan: 46 μm grit → ganaax: 4 μm grit) si loo baabi'iyo waxyeelada dusha sare, gaaritaanka> 10,000 wareegyada isku halaynta baaskiil wadida. Tani waxay muhiim u tahay rogayaasha EV, halkaas oo 10 μm dhumucdiisuna SiC wafer ay hagaajiyaan xawaaraha beddelka 30% .

• Qalabka Korantada ee GaN-on-SiC: khafiifinta wafer ilaa 80 μm waxay wanaajisaa dhaqdhaqaaqa elektaroonigga ah (μ> 2000 cm²/V·s) ee 650V GaN HEMTs, hoos u dhigista khasaaraha korantada 18%. Nidaamku waxa uu isticmaalaa dicing-ka caawiya laser-ka si looga hortago dildilaaca inta lagu jiro khafiifinta, gaaritaanka <5 μm cidhifyada cidhifka ee cod-weyneyaasha RF.

3. Optoelectronics

• GaN-on-SiC LEDs: 50 μm sapphire substrates waxay hagaajiyaan waxtarka soo saarista iftiinka (LEE) ilaa 85% (marka laga reebo 65% ee 150 μm wafers) iyadoo la yareynayo dabinka sawir-qaadista. Qalabkayaga kontoroolka TTV ee aadka u hooseeya (<0.3 μm) wuxuu xaqiijiyaa qiiqa LED-ka ee isku midka ah ee dhex dhexaadinta 12-inch, oo muhiim u ah bandhigyada Micro-LED ee u baahan lebbiska mawjada dhererka <100nm.

• Silikoon Photonics: Waferrada silikoon ee dhumucdiisu tahay 25μm waxay awood u siinaysaa 3 dB/cm luminta faafinta hoose ee hagaha mawjadaha, lama huraanka u ah 1.6 Tbps transceivers indhaha. Nidaamku waxa uu isku daraa simay CMP si loo yareeyo qallafsanaanta dusha sare ilaa Ra <0.1 nm, iyada oo kor u qaadaysa waxtarka isku xidhka 40%.

4. Dareemayaasha MEMS

• Xawaareyaal: 25 μm waferrada silikoon waxay gaadhaan SNR>85 dB (marka loo eego 75 dB ee 50 μm wafers) iyadoo kordhinaysa dareenka barakaca caddaynta. Nidaamkeena shiidida dhidibada laba-geesoodka ah ayaa magdhow u ah culeysyada walbahaarka, isaga oo hubinaya <0.5% dareenka dareenka ka sarreeya -40°C ilaa 125°C. Codsiyada waxaa ka mid ah ogaanshaha shilalka baabuurta iyo AR/VR dabagalka dhaqdhaqaaqa.

• Dareemayaasha cadaadiska: khafiifinta ilaa 40 μm waxay awood u siinaysaa 0-300 cabbir cabbirka <0.1% FS hysteresis. Isticmaalka isku-xidhka ku-meel-gaadhka ah (sidayaal galaas), geeddi-socodku wuxuu ka fogaanayaa jabka wafer inta lagu jiro etching dhinaca dambe, gaaritaanka <1 μm dulqaadka cadaadiska xad-dhaafka ah ee dareemayaasha IoT ee warshadaha.

Isku-dhafka Farsamada: Qalabkeena khafiifinta waferka wuxuu mideeyaa shiididda makaanikada, CMP, iyo etching balaasmaha si wax looga qabto caqabadaha kala duwan ee agabka (Si, SiC, Sapphire). Tusaale ahaan, GaN-on-SiC waxay u baahan tahay shiidid isku-dhafan (taageerayaal dheeman + balasma) si loo miisaamo adkaanta iyo ballaadhinta kulaylka, halka dareemayaasha MEMS ay dalbadaan qallafsanaanta dusha sare ee 5 nm iyada oo loo marayo polishing CMP.

• Saamaynta Wershadaha: Iyada oo awood u siinaysa waferrada dhuuban, waxqabadka sare leh, tignoolajiyadani waxay kaxaynaysaa hal-abuurka AI chips, 5G mmWave modules, iyo elektaroonigga dabacsan, oo leh dulqaadka TTV <0.1 μm ee bandhigyada laalaabi karo iyo <0.5 μm ee dareemayaasha LiDAR baabuurta.

Adeegyada XKH

1. Xalka la habeeyey

Qaabaynta La Milicsan Karo: Nashqadaha qolka 4-12-inch oo leh soo dejin toos ah.

Taageerada Doping: Cuntooyinka gaarka ah ee kiristaalo Er/Yb-doped iyo wafers InP/GaAs.

2. Dhamaadka-ilaa-Dhamaadka Taageerada

Horumarinta Habraaca: Tijaabada bilaashka ah waxay ku socotaa hagaajin.

Tababarka Caalamiga ah: Aqoon-is-weydaarsiyo farsamo sannad kasta oo ku saabsan dayactirka iyo cilad-saarka.

3. Nidaaminta Qalabka Kala Duwan

SiC: Wafer khafiifinta ilaa 100 μm oo leh Ra <0.1 nm.

Sapphire: dhumucdiisuna tahay 50μm daaqadaha laser UV (gudbinta> 92% @ 200 nm).

4. Adeegyada Qiimaha lagu daray

Alaabada la isticmaali karo: Taayirrada dheemanka (2000+ wafers/nolosha) iyo slurries CMP.

Gabagabo

Qalabkan khafiifinta wafer-ku waxa uu keenaa saxsanaanta hogaaminaysa wershadaha, kala duwanaanta agabka, iyo automation smart, taas oo ka dhigaysa lama huraan u ah is dhexgalka 3D iyo korontada. Adeegyada dhamaystiran ee XKH-laga bilaabo habaynta ilaa habaynta ka dib-hubi in macaamiishu ay gaadhaan hufnaanta kharashka iyo wax qabad heer sare ah wax soo saarka semiconductor.