Habka CVD ee loogu talagalay soo saarista alaabta cayriin ee SiC ee nadiifka ah ee foornada silikoon carbide ee foornada 1600 ℃

Mabda'a shaqada:

1. Precursor sahayda. Ilaha Silikoon (tusaale SiH₄) iyo isha kaarboon (tusaale C₃H₈) gaasasku waa la isku qasan yahay qiyaas ahaan waxaana la geeyaa qolka falcelinta.

2. Heerkulka sare ee burburka: Heerkulka sare ee 1500 ~ 2300 ℃, burburka gaaska wuxuu abuuraa Si iyo C atamka firfircoon.

3. falcelinta dusha sare: Si iyo atamka C waxa lagu shubaa dusha sare si ay u sameeyaan lakabka SiC crystal.

4. Kobaca Crystal: Iyadoo la xakameynayo heerkulka heerkulka, socodka gaaska iyo cadaadiska, si loo gaaro korriinka jihada ee dhidibka c ama dhidibka.

Halbeegyada muhiimka ah:

Heerkulka: 1600 ~ 2200℃ (>2000℃ ee 4H-SiC)

Cadaadiska: 50 ~ 200mbar (cadaadiska hoose si loo yareeyo nukleemka gaaska)

Saamiga gaaska: Si/C≈1.0~1.2 (si looga fogaado cilladaha kobcinta Si ama C)

Tilmaamaha ugu muhiimsan:

(1) Tayada crystal

Cufnaanta cilladda yar: cufnaanta microtubule <0.5cm ⁻², cufnaanta kala-baxa <10⁴ cm⁻².

Xakamaynta nooca Polycrystalline: waxay kori kartaa 4H-SiC (guud ahaan), 6H-SiC, 3C-SiC iyo noocyada kale ee crystal.

(2) Waxqabadka qalabka

Dejinta heerkulka sare: graphite induction kuleylinta ama kulaylka iska caabinta, heerkulka> 2300 ℃.

Xakamaynta midaysan: isbedbeddelka heerkulka ± 5℃, heerka kobaca 10 ~ 50μm / h.

Nidaamka Gaaska: Qiyaasta qulqulka saxda ah ee saxda ah (MFC), nadiifnimada gaaska ≥99.999%.

(3) Faa'iidooyinka farsamada

Nadaafad sare: Diiradda wasakhda asalka ah <10¹⁶ cm⁻³ (N, B, iwm.).

Cabbirka weyn: Taageerada 6 "/8" koritaanka substrate-ka SiC.

(4) Isticmaalka tamarta iyo qiimaha

Isticmaalka tamarta sare (200 ~ 500kW · h foornada), xisaabinta 30% ~ 50% qiimaha wax soo saarka ee SiC substrate.

Codsiyada muhiimka ah:

1. Substrate semiconductor Power: SiC MOSFETs ee loogu talagalay soo saarista baabuurta korantada iyo rogayaasha sawirkavoltaic.

2. Qalabka Rf: Saldhigga 5G ee GaN-on-SiC substrate epitaxial.

3.Aaladaha deegaanka Extreme: dareemayaasha heerkulka sare ee hawada iyo dhirta tamarta nukliyeerka.

Tilmaamaha farsamada:

| Tilmaamid | Faahfaahin |

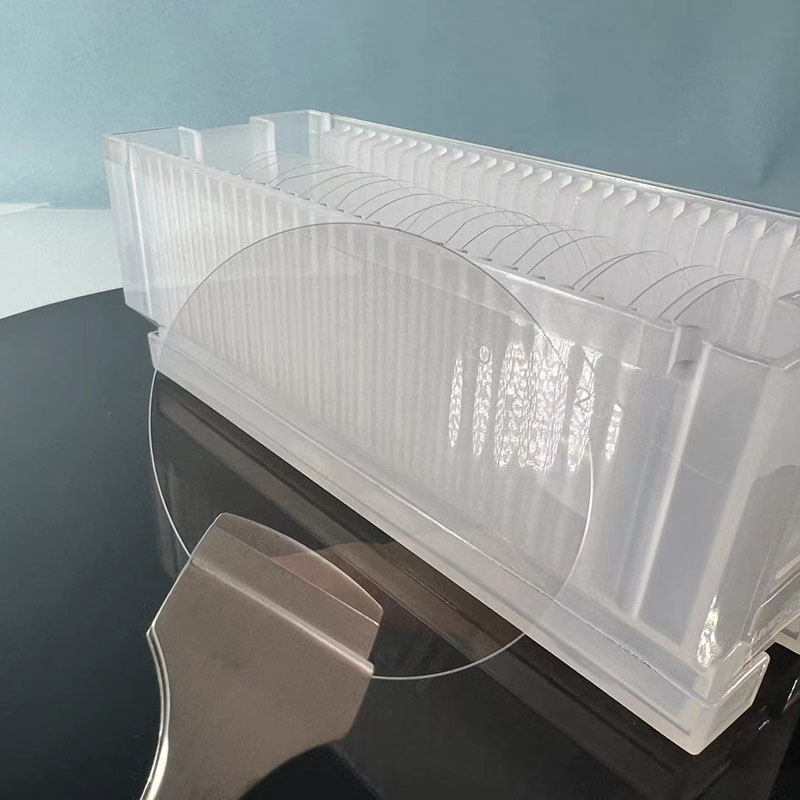

| Cabirka (L × W × H) | 4000 x 3400 x 4300 mm ama habee |

| Dhexroor qolka foornada | 1100mm |

| Awoodda rarista | 50kg |

| Xadka vacuum degree | 10-2Pa (2saac ka dib marka bamka molecular uu bilaabo) |

| Heerka kor u kaca cadaadiska qolka | ≤10Pa/saac (calcination ka dib) |

| Foornada hoose waxay daboolaysaa istaroogga qaadista | 1500mm |

| Habka kululaynta | Kuleylinta soo kicinta |

| Heerkulka ugu badan ee foornada | 2400°C |

| Korontada kululaynta | 2X40kW |

| Cabbirka heerkulka | Cabbiraadda heerkulka infrared laba-midab ah |

| Kala duwanaanta heerkulka | 900 ~ 3000 ℃ |

| Saxnaanta xakamaynta heerkulka | ±1°C |

| Xakamaynta kala duwanaanshaha cadaadiska | 1 ~ 700mbar |

| Saxnaanta Xakamaynta Cadaadiska | 1 ~ 5mbar ± 0.1mbar; 5 ~ 100mbar ± 0.2mbar; 100 ~ 700mbar ± 0.5mbar |

| Habka rarista | loading hoose; |

| Qaabeynta ikhtiyaariga ah | Barta cabbiraadda heerkulka labanlaab, dejinta fargeeto. |

Adeegyada XKH:

XKH waxay bixisaa adeegyo wareeg ah oo buuxa oo loogu talagalay foornooyinka silikoon carbide CVD, oo ay ku jiraan hagaajinta qalabka (naqshadeynta aagga heerkulka, qaabeynta nidaamka gaaska), horumarinta habka (xakamaynta crystal, hagaajinta cilladda), tababarka farsamada (shaqeynta iyo dayactirka) iyo taageerada iibka ka dib (qaybaha firaaqada ee qaybaha muhiimka ah, ogaanshaha fog) si ay u caawiyaan macaamiisha inay gaaraan wax soo saarka substrate-ka SiC tayo sare leh. Iyo in la bixiyo adeegyada cusboonaysiinta nidaamka si si joogto ah loo hagaajiyo wax-soo-saarka crystal iyo hufnaanta korriinka.