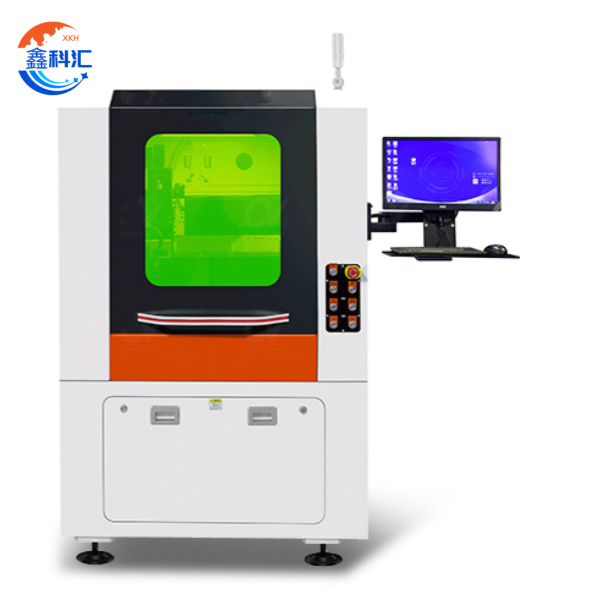

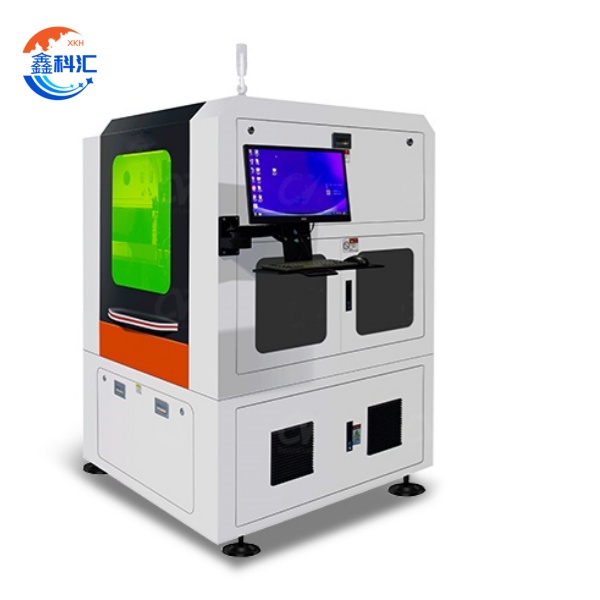

Mashiinka feerka leysarka miiska yar 1000W-6000W daloolinta ugu yar 0.1MM waxaa loo isticmaali karaa qalabka dhoobada biraha

Qalabka lagu dabaqi karo

1. Qalabka birta ah: sida aluminium, copper, titanium alloy, birta aan lahayn, iwm.

2. Qalabka aan biraha ahayn: sida balaastikada (oo ay ku jiraan polyetylen PE, polypropylene PP, polyester PET iyo filimo kale oo caag ah), galaas (oo ay ku jiraan galaas caadi ah, galaas gaar ah sida galaas ultra-cad, galaas K9, galaas borosilicate sare, galaas quartz, iwm, laakiin galaas dabcay ay sabab u tahay guryaha gaarka ah ee waraaqaha), maqaar iyo dhoobada ma ku haboon yihiin on guryaha gaarka ah ee jirka), maqaar iyo dhoobada.

3. Walxaha isku dhafan: oo ka kooban laba ama in ka badan oo walxo leh sifooyin kala duwan iyada oo loo marayo hababka jireed ama kiimikooyinka, oo leh sifooyin dhammaystiran oo heer sare ah.

Qalabka 4.Special: Meelaha gaarka ah, mashiinnada feerka laysarka ayaa sidoo kale loo isticmaali karaa si loo farsameeyo qaar ka mid ah qalabka gaarka ah.

Halbeegyada qeexida

| Magaca | Xogta |

| Awoodda leysarka: | 1000W-6000W |

| Saxnimada goynta: | ±0.03MM |

| Aperture-qiimaha ugu yar: | 0.1MM |

| Dhererka goynta: | 650MM×800MM |

| Saxnaanta booska: | ≤±0.008MM |

| Saxnaanta soo noqnoqda: | 0.008MM |

| Gaaska jarista: | Hawada |

| Qaab go'an: | Xakamaynta cidhifka oofwareenka, taageerada qalabka |

| Habka wadista: | Matoorka toosan ee joojinta magnetic |

| Dhumucda goynta | 0.01MM-3MM |

Faa'iidooyinka farsamada

1.Doolista waxtarka leh: Isticmaalka laydhka tamarta sare ee tamarta sare ee farsamaynta aan la xiriirin, si degdeg ah, 1 ilbiriqsi si loo dhamaystiro farsamaynta godadka yaryar.

2.High sax ah: Iyadoo si sax ah loo xakameynayo awoodda, garaaca garaaca wadnaha iyo booska diiradda laser, hawlgalka qodista leh saxnaanta micron ayaa la gaari karaa.

3. Si ballaaran loo dabaqi karo: waxay farsameyn kartaa noocyo kala duwan oo jajab ah, oo ay adag tahay in la farsameeyo iyo qalab gaar ah, sida caag, caag, bir ah (birta aan fiicnayn, aluminium, copper, titanium alloy, iwm), galaas, ceramics iyo wixii la mid ah.

4. Hawlgalka caqliga leh: Mashiinka feerka laysarka wuxuu ku qalabaysan yahay nidaamka xakamaynta tirooyinka sare, kaas oo ah mid aad u caqli badan oo sahlan in lagu dhex daro naqshadeynta kumbuyuutarka iyo nidaamka wax soo saarka ee ku caawiya kombuyuutarka si loo xaqiijiyo barnaamijyada degdegga ah iyo hagaajinta baaska adag iyo habka wax soo saarka.

Xaaladaha shaqada

1.Diversity: waxay fulin kartaa noocyo kala duwan oo ka mid ah habaynta daloolka qaabka adag, sida godadka wareegsan, godadka labajibbaaran, godadka saddex xagal iyo godadka kale ee gaarka ah.

2.High Tayada: Tayada daloolku waa mid sarreeya, cidhifkuna waa siman yahay, ma jiro dareen qallafsan, iyo qallafsanaantu waa yar tahay.

3.Automation: Waxay dhamaystiri kartaa farsamaynta godka-yar-yar oo leh cabbir isku mid ah iyo qaybinta lebbiska hal mar, waxayna taageertaa habka daloolka kooxeed iyada oo aan faragelin gacanta ah.

Astaamaha qalabka

■ Xajmiga yar ee qalabka, si loo xalliyo dhibaatada meel cidhiidhi ah.

■ Saxnaanta sare, daloolka ugu badan wuxuu gaari karaa 0.005mm.

■ Qalabku waa sahlan yahay in lagu shaqeeyo waana fududahay in la isticmaalo.

■ Isha iftiinka waxaa lagu beddeli karaa iyadoo loo eegayo walxo kala duwan, iswaafajintuna waa ka sii xoog badan tahay.

■ Meel yar oo kulaylku saameeyay, oksaydhisku yaraanta hareeraha godadka.

Goobta codsiga

1. Warshadaha Elektarooniga ah

●Printed Circuit Board (PCB) feedh:

Makiinadaha Microhole: Waxaa loo isticmaalaa farsamaynta godad yar oo dhexroorkiisu ka yar yahay 0.1mm PCBS si loo daboolo baahiyaha looxyada isku xidhka cufnaanta sare (HDI).

Godad indho la'aan ah oo la aasay: Mashiinka indhoolayaasha iyo godadka lagu aasay PCBS-da lakabyo badan si loo hagaajiyo waxqabadka iyo isdhexgalka guddiga.

●Baakadaha semiconductor:

Qodista qaabka rasaasta: Godad sax ah ayaa lagu farsameeyay qaabka hogaanka semiconductor si loogu xidho jajabka wareegga dibadda.

Gargaarka wafer goynta: Feer godadka maraqa si aad u caawiso goynta iyo hababka baakadaha xiga.

2. Mashiinnada saxda ah

● Habaynta qaybaha yaryar:

Qodista marshada saxda ah: Mashiinka godadka saxda ah ee saxda ah ee qalabka yar yar ee hababka gudbinta saxda ah.

Qodista qayb ka mid ah dareemayaasha: Mashiinada microholes ee qaybaha dareemayaasha si loo hagaajiyo dareenka iyo xawaaraha jawaabta dareenka.

●Wax-soo-saarka caaryada:

Dalool qaboojinta caaryada: Makiinado qaboojinta daloolka duridda ama dhinta tuurista caaryada si kor loogu qaado waxqabadka kulaylka caaryada.

Habaynta hawo-mareenka: Makiinada hawo-mareenada yaryar ee caaryada si loo yareeyo cilladaha samaynta.

3. Qalabka caafimaadka

●Qalabka qaliinka ee ugu yar:

Daloolinta kateetarka: Microholes waxaa lagu farsameeyaa kateeterada qalliinka ee ugu yar ee galitaanka daawada ama dheecaanka dareeraha.

Qaybaha Endoscope: godadka saxda ah waxaa lagu farsameeyaa muraayada ama madaxa qalabka ee endoscope si loo hagaajiyo shaqeynta qalabka.

●Nidaamka gaarsiinta daroogada:

Qoditaanka array Microneedle: Machining microholes ee balastar daawada ama qalab microneedle si loo xakameeyo heerka siideynta daawada.

Qodista Biochip: Microholes waxaa lagu farsameeyaa biochips si loo ogaado dhaqanka unugyada.

4. Qalabka indhaha

● Xidhiidhiyaha Fiber optic:

Qulqulka daloolka dhamaadka fiber-ka indhaha: Mashiinnada microholes ee wejiga dhamaadka xiriiriyaha indhaha si loo hagaajiyo hufnaanta gudbinta calaamadaha indhaha.

Mashiinka array-ga fiber-ka: Mashiinka godadka saxanka sare leh ee saxanka array-ga fiber-ka ee isgaadhsiinta indhaha ee kanaalka badan.

Filterka indhaha:

Qulqulka shaandhaynta: Makiinada godad yaryar ee shaandhada indhaha si loo gaadho xulashada mawjadaha dhaadheer ee gaarka ah.

Makiinadaha kala-duwan ee curiyaha: Makiinada microholes ee curiyayaasha indhaha kala duwan ee kala goynta laysarka ama qaabaynta

5. Samaynta baabuurta

●Nidaamka durista shidaalka:

Feeritaanka biibiile: Ka-shaqaynta godad-yar-yar oo duleelka duritaanka si kor loogu qaado saamaynta atomization shidaalka oo loo hagaajiyo waxtarka gubashada.

●Wax soo saarka dareemayaasha:

Qulqulka dareemaha cadaadiska: Mashiinnada microholes ee dareemaha cadaadiska diaphragm si loo hagaajiyo dareenka iyo saxnaanta dareemayaasha.

●Bateriga korontada:

Qodista tirka baytariyada: Mashiinada microholes ee shilalka batteriga lithium si loo hagaajiyo dhexgalka korantada iyo gaadiidka ion.

XKH waxay bixisaa adeegyo kala duwan oo kala duwan oo hal-joojin ah oo loogu talagalay dalooliyeyaasha laysarka miiska yar, oo ay ku jiraan laakiin aan ku xaddidnayn: La-talinta iibka xirfadleyda, naqshadeynta barnaamijka, sahayda qalab tayo sare leh, rakibid wanaagsan iyo hawlgelin, tabobar hawleed oo faahfaahsan, si loo hubiyo in macaamiishu helaan adeegga ugu waxtarka badan, saxda ah iyo taxaddar la'aanta ee habka feerka.

Jaantus faahfaahsan