SiO₂ Quartz Wafer Quartz Wafers SiO₂ MEMS Heerkulka 2″ 3″ 4″ 6″ 8″ 12″

Jaantus faahfaahsan

Hordhac

Waferrada Quartz waxay door lama huraan ah ka ciyaaraan horumarinta qalabka elektiroonigga ah, semiconductor, iyo warshadaha indhaha. Laga helay talefannada casriga ah ee hagaya GPS-kaaga, oo ku guntan saldhigyada saldhigyada soo noqnoqda ee awoodda leh ee awoodda shabakadaha 5G, oo lagu dhex daray aaladaha soo saara microchips-ka xiga, waferrada quartz waa lama huraan. Substrate-yadan saafiga ah ee sarreeya ayaa awood u siinaya hal-abuurnimo wax kasta laga bilaabo xisaabinta quantum ilaa sawir-qaadista horumarsan. Inkasta oo laga soo qaatay mid ka mid ah macdanta ugu badan ee Dunida, waferrada quartz ayaa lagu farsameeyay heerar aan caadi ahayn oo sax ah iyo waxqabad.

Waa maxay Quartz Wafers

Waferrada Quartz waa dhuuban, saxanno wareeg ah oo laga sameeyay crystal quartz synthetic ultra-pure. Waxaa lagu heli karaa dhexroorka caadiga ah ee u dhexeeya 2 ilaa 12 inji, waferrada quartz sida caadiga ah waxay u dhexeeyaan dhumucdiisu tahay 0.5 mm ilaa 6 mm. Si ka duwan quartz dabiiciga ah, kaas oo sameeya kiristaalo prismatic ah oo aan caadi ahayn, quartz synthetic waxa lagu koray xaaladaha shaybaadhka si adag loo xakameeyay, iyada oo soo saarta qaab-dhismeedyo crystals isku mid ah.

Karistalinnimada dabiiciga ah ee waferrada quartz waxay bixisaa iska caabin kiimikaad oo aan isbarbardhigi karin, hufnaanta indhaha, iyo xasilloonida heerkulka sare iyo cadaadiska farsamada. Tilmaamahani waxay ka dhigaan waferrada quartz qayb aasaasi ah oo loogu talagalay aaladaha saxda ah ee loo isticmaalo gudbinta xogta, dareenka, xisaabinta, iyo tignoolajiyada ku salaysan leysarka.

Tilmaamaha Wafer Quartz

| Nooca Quartz | 4 | 6 | 8 | 12 |

|---|---|---|---|---|

| Cabbirka | ||||

| Dhexroorka (inj) | 4 | 6 | 8 | 12 |

| Dhumucda (mm) | 0.05–2 | 0.25-5 | 0.3-5 | 0.4-5 |

| Dulqaadka dhexroorka (inch) | ±0.1 | ±0.1 | ±0.1 | ±0.1 |

| Dulqaadashada Dhumucda (mm) | La beddeli karo | La beddeli karo | La beddeli karo | La beddeli karo |

| Guryaha indhaha | ||||

| Tusmada dib-u-celinta @365 nm | 1.474698 | 1.474698 | 1.474698 | 1.474698 |

| Tusmada dib-u-celinta @546.1 nm | 1.460243 | 1.460243 | 1.460243 | 1.460243 |

| Tusmada dib-u-celinta @1014 nm | 1.450423 | 1.450423 | 1.450423 | 1.450423 |

| Gudbinta Guddaha (1250-1650 nm) | >99.9% | >99.9% | >99.9% | >99.9% |

| Wadarta Gudbinta (1250-1650 nm) | >92% | >92% | >92% | >92% |

| Tayada Mashiinka | ||||

| TTV (Wadarta kala duwanaanshaha dhumucda, µm) | <3 | <3 | <3 | <3 |

| Bannaanka (µm) | ≤15 | ≤15 | ≤15 | ≤15 |

| Dusha sare (nm) | ≤1 | ≤1 | ≤1 | ≤1 |

| Qaaso (µm) | <5 | <5 | <5 | <5 |

| Guryaha Jirka | ||||

| Cufnaanta (g/cm³) | 2.20 | 2.20 | 2.20 | 2.20 |

| Modulka Da'da yar (GPa) | 74.20 | 74.20 | 74.20 | 74.20 |

| Mohs Hardness | 6–7 | 6–7 | 6–7 | 6–7 |

| Modulus Shear (GPa) | 31.22 | 31.22 | 31.22 | 31.22 |

| Saamiga Poisson | 0.17 | 0.17 | 0.17 | 0.17 |

| Xoog isku dhejisan (GPa) | 1.13 | 1.13 | 1.13 | 1.13 |

| Xoogga Jilitaanka (MPa) | 49 | 49 | 49 | 49 |

| Dielectric Constant (1 MHz) | 3.75 | 3.75 | 3.75 | 3.75 |

| Guryaha kulaylka | ||||

| Dhibicda Cadaadiska (10¹⁴.⁵ Pa·s) | 1000°C | 1000°C | 1000°C | 1000°C |

| Barta Annealing (10¹³ Pa·s) | 1160°C | 1160°C | 1160°C | 1160°C |

| Meesha Jilicsan (10⁷.⁶ Pa·s) | 1620°C | 1620°C | 1620°C | 1620°C |

Codsiyada Quartz Wafers

Waferrada Quartz waxaa si gaar ah loo farsameeyay si ay ula kulmaan codsiyada u baahan warshadaha oo ay ka mid yihiin:

Elektrooniga iyo Aaladaha RF

- Waferrada Quartz waxay udub dhexaad u yihiin resonators crystal quartz iyo oscillators kuwaas oo bixiya calaamadaha saacada ee casriga ah, unugyada GPS, kombiyuutarada, iyo qalabka isgaarsiinta wireless.

- Balaadhintooda kulaylka hooseeya iyo Q-factor-sare waxay ka dhigaan wafers quartz mid ku habboon wareegyada waqtiga xasilloonida iyo filtarrada RF.

Optoelectronics iyo Imaging

- Waferrada Quartz waxay bixiyaan gudbinta UV iyo IR heer sare ah, taas oo ka dhigaysa mid ku habboon muraayadaha indhaha, kala qaybinta alwaaxyada, daaqadaha laysarka, iyo qalabka wax baadha.

- Iska caabbinta shucaaca ayaa awood u leh isticmaalka fiisigiska tamarta sare leh iyo qalabka hawada sare.

Semiconductor iyo MEMS

- Waferrada Quartz waxay u adeegaan sidii substrate-ka wareegyada semiconductor-ka ee soo noqnoqda, gaar ahaan codsiyada GaN iyo RF.

- MEMS (Nidaamka Micro-Electro-Mechanical Systems), waferrada quartz waxay u beddelaan calaamadaha farsamada kuwa korantada iyada oo loo marayo saameynta piezoelectric, taasoo awood u siinaysa dareemayaasha sida gyroscopes iyo accelerometers.

Wax-soo-saarka Sare & Shaybaadhka

- Waferrada quartz ee nadiifka ah ayaa si weyn loogu isticmaalaa kiimikaad, biomedical, iyo shaybaarada photonic ee unugyada indhaha, cuvettes UV, iyo maaraynta muunad heerkul sare leh.

- La jaanqaadkooda bay'ad aad u daran ayaa ka dhigaysa inay ku habboon yihiin qolalka balaasmaha iyo agabka dhigaalka.

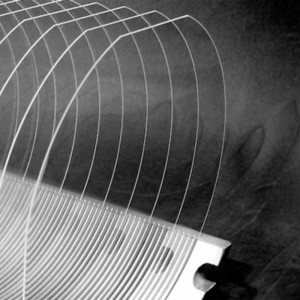

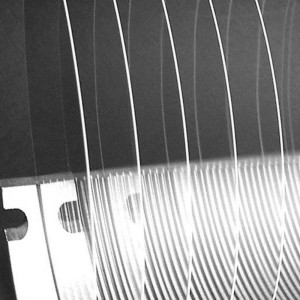

Sida loo Sameeyo Wafers Quartz

Waxaa jira laba dariiqo wax soo saarka aasaasiga ah ee wafers quartz:

Wafers Quartz Fused

Wafers quartz fused waxaa lagu sameeyaa iyadoo dhalaalaysa granules quartz-dabiiciga ah galaas amorphous ah, ka dibna jeexjeexa oo nadiifiya block adag oo ka dhigaya maraqyo khafiif ah. Waferradan quartz waxay bixiyaan:

- Daah-furnaanta UV-ga gaarka ah

- Kala duwanaansho kuleyl ballaaran oo shaqeynaya (>1100°C)

- Iska caabin shoog kulayl heer sare ah

Waxay ku fiican yihiin qalabka lithography, foornooyinka heerkulka sare, iyo daaqadaha indhaha laakiin kuma habboona codsiyada piezoelectric sababtoo ah la'aanta nidaamka crystalline.

Quartz Wafers Dhaqan

Wafers quartz-dhaqameedka ah ayaa loo koraa si synthetic si ay u soo saaraan kiristaalo aan cillad lahayn oo leh jihayn toosan. Waferradan waxa loo habeeyey codsiyada u baahan:

- Xaglo gooyay oo sax ah (X-, Y-, Z-, AT-cut, iwm.)

- Oscillators-soo noqnoqda-sare iyo filtarrada SAW

- Polarizer-yada indhaha iyo aaladaha MEMS ee horumarsan

Habka wax-soo-saarka ayaa ku lug leh koritaanka abuurka autoclaves, oo ay ku xigto jeexid, hanuunin, nuugista, iyo nadiifinta.

Alaab-qeybiyeyaasha Wafer Quartz ee hormuudka ka ah

Alaab-qeybiyeyaasha caalamiga ah ee ku takhasusay waferrada quartz-ka ee saxda ah waxaa ka mid ah:

- Heraeus(Jarmalka) - Quartz la isku daray iyo synthetic

- Shin-Etsu Quartz(Japan) - xalalka wafer-nadiifinta sare leh

- WaferPro(Mareykanka) - wafers quartz dhexroor ballaaran iyo substrates

- Korth Kristale(Jarmalka) - Wafers crystal synthetic

Doorka Isbadalaya ee Quartz Wafers

Wafers Quartz waxay sii wadaan inay u koraan sidii qaybaha muhiimka ah ee muuqaalka tignoolajiyada ee soo baxaya:

- Yaraynta- Wafers-ka Quartz waxaa lagu sameeyay dulqaad adag oo loogu talagalay isdhexgalka qalabka.

- Soo noqnoqoshada Sare ee Elektarooniga ah- Naqshado wafer cusub oo quartz ah ayaa ku riixaya mmWave iyo THz domains ee 6G iyo radar.

- Next-Gen Sensing- Laga soo bilaabo baabuurta iskeed u madaxbannaan ilaa warshadaha IoT, dareemayaasha quartz-ku-salaysan ayaa noqda kuwa aad muhiim u ah.

Su'aalaha inta badan la iska weydiiyo ee ku saabsan waferrada quartz

1. Waa maxay waferka quartz?

Waferka quartz waa saxan fidsan oo khafiif ah oo laga sameeyay silikoon dioxide crystalline (SiO₂), oo sida caadiga ah lagu soo saaray cabbirada semiconductor ee caadiga ah (tusaale, 2, 3, 4, 6, 8, ama 12)). Waxaa loo yaqaanaa nadiifnimadeeda sare, xasiloonida kulaylka, iyo hufnaanta indhaha, wafer quartz waxaa loo isticmaalaa sidii substrate ama sideyaal codsiyo kala duwan oo sax ah oo kala duwan sida farsamaynta semiconductor, aaladaha MEMS, nidaamyada indhaha, iyo hababka faakuumka.

2. Waa maxay faraqa u dhexeeya quartz iyo jel silica?

Quartz waa qaab adag oo silikoon dioxide ah (SiO₂), halka jelka silica uu yahay qaab amorphous iyo dalool ah oo SiO₂ ah, oo caadi ahaan loo isticmaalo qallajiye si loo nuugo qoyaanka.

- Quartz waa adag tahay, daah-furan, waxaana loo isticmaalaa codsiyada elektarooniga ah, indhaha, iyo warshadaha.

- Jeelka silica wuxuu u muuqdaa sidii kuul yar yar ama granules waxaana ugu horreyn loo isticmaalaa xakamaynta qoyaanka ee baakadaha, elektiroonigga, iyo kaydinta.

3. Maxaa loo isticmaalaa kiristaalo quartz?

Kiristaalo Quartz ayaa si weyn loogu isticmaalaa qalabka elektiroonigga ah iyo optics-ka sababtoo ah sifooyinka piezoelectric (waxay abuuraan kharash koronto oo hoos yimaada cadaadiska farsamada). Codsiyada caadiga ah waxaa ka mid ah:

- Oscillators iyo xakamaynta soo noqnoqda(tusaale, saacada quartz, saacado, microcontrollers)

- Qaybaha indhaha(tusaale, muraayadaha, muraayadaha hirarka, daaqadaha)

- Resonators iyo filtarradaRF iyo qalabka isgaarsiinta

- Dareemayaashacadaadis, dardargelin, ama xoog

- Samaynta Semiconductorsida substrates ama habaynta daaqadaha

4. Waa maxay sababta quartz loogu isticmaalo microchips?

Quartz waxaa loo isticmaalaa codsiyada la xiriira microchip sababtoo ah waxay bixisaa:

- Deganaanshaha kulaylkainta lagu guda jiro hababka heerkulka sare sida faafinta iyo annealing

- dahaarka korontadasababtoo ah sifooyinka dielectric

- Iska caabin kiimikaadasiidhyada iyo dareerayaasha loo isticmaalo samaynta semiconductor

- Saxnaanta cabbirkaiyo balaadhinta kulaylka hoose ee toosinta lithography ee la isku halayn karo

- Iyadoo quartz lafteedu aan loo isticmaalin maadada semiconductor ee firfircoon (sida silikoon), waxay door muhiim ah ka ciyaartaa jawiga wax-soo-saarka-gaar ahaan foornooyinka, qolalka, iyo substrate-ka sawir-qaadista.

Annaga

XKH waxay ku takhasustay horumarinta tignoolajiyada sare, wax soo saarka, iyo iibinta muraayadaha indhaha ee gaarka ah iyo agabka cusub ee crystal. Badeecadahayadu waxay u adeegaan qalabka elektarooniga ah, elektiroonigga macaamiisha, iyo militariga. Waxaan bixinaa qaybaha indhaha ee Sapphire, daboolka muraayadda taleefanka gacanta, Ceramics, LT, Silicon Carbide SIC, Quartz, iyo maraqyada crystal semiconductor. Iyada oo leh khibrad xirfad leh iyo qalab-goynta, waxaan ku fiicanahay habaynta badeecada aan caadiga ahayn, annagoo higsanayna inaan noqono hormuudka agabka optoelectronic shirkad farsamo sare leh.