Saxeexa dhoobada ee Silicon Carbide - Saxaarada Joogta ah, Waxqabadka Sare ee Codsiyada Kulul iyo Kiimikada

Jaantus faahfaahsan

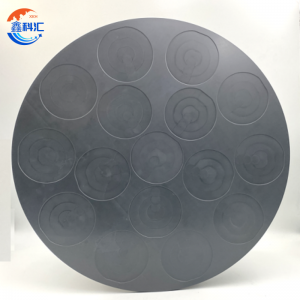

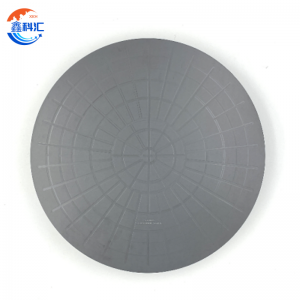

Hordhac Product

Saxarada dhoobada ah ee Silicon carbide (SiC) waa qaybo waxqabad sare leh oo si balaadhan loogu isticmaalo heerkul sare, raran, iyo jawi adag oo kiimikaad ah. Waxaa laga farsameeyay agabyo dhoobada silikoon carbide oo horumarsan, saxaaradhan waxaa loogu talagalay in lagu bixiyo awood farsamo oo gaar ah, kulaylka sareeyo, iyo iska caabbinta shoogga kulaylka, oksaydhka, iyo daxalka. Dabeecaddooda adag ayaa ka dhigaysa inay aad ugu habboon yihiin codsiyada warshadaha kala duwan oo ay ku jiraan wax soo saarka semiconductor, farsamaynta sawir-qaadista, qaybinta qaybaha birta budada ah, iyo in ka badan.

Saxanadaha Silicon carbide waxay u adeegaan sida sideyaal ama taageerooyin lama huraan ah inta lagu jiro hababka daaweynta kulaylka halkaasoo saxnaanta cabbirka, sharafta qaabdhismeedka, iyo iska caabbinta kiimikadu ay muhiim tahay. Marka la barbar dhigo alaabada dhoobada dhaqameed sida alumina ama mullite, saxarada SiC waxay bixiyaan waxqabad aad u sarreeya, gaar ahaan xaaladaha ku lug leh baaskiil kulaylka soo noqnoqda iyo jawi dagaal leh.

Habka Wax-soo-saarka & Qalabaynta Qalabka

Soo saarista saxarada dhoobada ee SiC waxay ku lug leedahay injineernimada saxda ah iyo tignoolajiyada horumarsan ee sintering si loo hubiyo cufnaanta sare, qaab-dhismeed yar oo isku mid ah, iyo waxqabad joogto ah. Tallaabooyinka guud waxaa ka mid ah:

-

Xulashada Qalabka Ceyriinka

Silikoon carbide budada ah oo nadiif ah oo nadiif ah (≥99%) ayaa la doortay, inta badan leh xakamaynta cabbirka walxaha gaarka ah iyo wasakhda ugu yar si loo dammaanad qaado sifooyinka farsamada iyo kulaylka sare. -

Hababka Samaynta

Iyada oo ku xidhan sifooyinka saxanka, farsamooyinka samaynta ee kala duwan ayaa la adeegsadaa:-

Cadaadiska qabow ee isostatic (CIP) ee cufnaanta sare, isafgaradka lebbiska ah

-

Soo saarista ama shubista sibidhka ee qaababka adag

-

Naqshadeynta duritaanka ee joomateriyada saxda ah, faahfaahsan

-

-

Farsamooyinka Sintering

Jirka cagaarka ah waxaa lagu miiray heerkul aad u sarreeya, sida caadiga ah inta u dhaxaysa 2000 ° C, oo ku hoos jira jawi aan shaqaynayn ama faaruq ah. Hababka wadaagga caadiga ah waxaa ka mid ah:-

Reaction Bonded SiC (RB-SiC)

-

Sintered SiC (SSiC) oo aan cadaadis lahayn

-

SiC dib loo cusboonaysiiyey (RBSiC)

Nidaam kastaa wuxuu keenaa waxyaabo yar oo kala duwan, sida porosity, xoog, iyo kulaylka kuleylka.

-

-

Machining sax ah

Ka dib marka la jeexjeexo, saxaarada ayaa lagu farsameeyaa si loo gaaro dulqaad cufan, dusha sare oo siman, iyo fidsanaan. Daawaynta dusha sare sida dharbaaxada, shiididda, iyo turxaan bixinta ayaa lagu dabaqi karaa iyadoo lagu salaynayo baahida macaamiisha.

Codsiyada caadiga ah

Saxarada dhoobada ee Silicon carbide waxaa loo isticmaalaa warshado kala duwan oo kala duwan taas oo ay ugu wacan tahay wax-qabadkooda iyo adkeysigooda. Codsiyada caadiga ah waxaa ka mid ah:

-

Warshadaha Semiconductor

Saxarada SiC waxa loo isticmaalaa sida sideyaal inta lagu guda jiro buxinta wafer, fidinta, oksaydhka, epitaxy, iyo hababka abuurka. Xasiloonidoodu waxay hubisaa qaybinta heerkulka isku midka ah iyo faddaraynta ugu yar. -

Wershadaha Photovoltaic (PV)

Soosaarka unugyada cadceedda, saxarada SiC waxay taageertaa ingots silikoon ama wafers inta lagu jiro fidinta heerkulka sare iyo tillaabooyinka qallafsan. -

Metallurgy Budada iyo Ceramics

Loo isticmaalo qaybaha taageerada inta lagu guda jiro sifeynta budada birta ah, ceramics, iyo walxaha isku dhafan. -

Muraayadaha iyo muraayadaha

Codsaday sidii saxaarad kiln ama goobo lagu sameeyo muraayadaha gaarka ah, substrate LCD, ama qaybaha kale ee indhaha. -

Habaynta Kiimikada iyo Foornooyinka kulaylka

U adeega sida sidayaal u adkaysta daxalka ee reactors kiimikaad ama sida saxaarad kaalmaysa kulaylka foornooyinka faaruqinta iyo hawada la kontoroolo.

Tilmaamaha Waxqabadka Muhiimka ah

-

✅Deganaanshaha kulaylka Gaarka ah

Waxay u adkaysataa isticmaalka joogtada ah ee heerkulka ilaa 1600-2000 ° C iyada oo aan la kicin ama hoos u dhicin. -

✅Xoogga Farsamada Sare

Waxay bixisaa xoog dabacsanaan sare leh (sida caadiga ah> 350 MPa), hubinta cimri dhererka xitaa xaaladaha culeyska sareeyo. -

✅Iska caabinta shoogga kulaylka

Wax qabad heer sare ah oo ka jira degaannada leh isbedbedelka heerkulka degdega ah, yaraynta khatarta dillaaca. -

✅Daxalka iyo iska caabinta Oxidation

Kiimiko ahaan ugu xasiloon inta badan asiidhka, alkalis, iyo oxidizing/yaraynta gaasta, oo ku habboon hababka kiimikada adag. -

✅Saxnaanta cabbirka iyo dabacsanaanta

Mashiin si sax ah loo sameeyay, hubinta farsamaynta lebbiska iyo waafaqid hababka otomaatiga ah. -

✅Cimriga Dheer & Waxtarka Kharashka

Heerarka beddelka hoose iyo kharashyada dayactirka oo la dhimay ayaa ka dhigaya xal kharash-ku-ool ah muddo ka dib.

Tilmaamaha Farsamada

| Halbeegga | Qiimaha caadiga ah |

|---|---|

| Qalab | Reaction Bonded SiC / Sintered SiC |

| Max. Heerkulka shaqada | 1600-2000°C |

| Xoog Jilicsan | ≥350 MPa |

| Cufnaanta | ≥3.0 g/cm³ |

| Habdhaqanka kulaylka | ~ 120-180 W/m·K |

| Dhulka Dusha sare | ≤ 0.1 mm |

| Dhumucda | 5-20 mm (la beddeli karo) |

| Cabirka | Heerka: 200×200 mm, 300×300 mm, iwm. |

| Dhamaystir dusha sare | Mashiin, la miiray (marka la codsado) |

Su'aalaha Inta Badan La Isweydiiyo (FAQ)

Q1: Ma lagu isticmaali karaa saxaarad carbide silicon ah foornooyinka faakuumka?

A:Haa, saxarada SiC waxay ku fiican yihiin bay'ada faaruqinta sababtoo ah gaaskooda oo hooseeya, xasiloonidooda kiimikada, iyo iska caabin heerkul sare ah.

Q2: Ma jiraan qaabab gaar ah ama boosaska la heli karo?

A:Dhab ahaantii. Waxaan bixinaa adeegyo habaynta oo ay ku jiraan cabbirka saxaaradda, qaabka, sifooyinka dusha sare (tusaale, jeexjeexyada, godadka), iyo nadiifinta dusha sare si loo buuxiyo shuruudaha macaamiisha gaarka ah.

Q3: Sidee SiC u barbardhigaa alumina ama saxarada quartz?

A:SiC waxay leedahay xoog sare, kuleyl kuleyl ka wanaagsan, iyo iska caabin heer sare ah ee shoogga kulaylka iyo daxalka kiimikada. Iyadoo alumina ay tahay mid kharash badan leh, SiC waxay si fiican u qabataa jawiga baahida.

Q4: Ma jiraa dhumucda caadiga ah ee saxaradan?

A:Dhumucdiisu waxay caadi ahaan ku jirtaa inta u dhaxaysa 5-20 mm, laakiin waxaan ku hagaajin karnaa iyada oo ku saleysan codsigaaga iyo shuruudaha xajinta.

Q5: Waa maxay wakhtiga hogaanka caadiga ah ee saxarada SiC ee la habeeyey?

A:Waqtiyada ledhku way kala duwan yihiin iyadoo ku xidhan kakanaanta iyo tirada laakiin guud ahaan waxay u dhaxaysaa 2 ilaa 4 toddobaad dalabyada la habeeyey.

Annaga

XKH waxay ku takhasustay horumarinta tignoolajiyada sare, wax soo saarka, iyo iibinta muraayadaha indhaha ee gaarka ah iyo agabka cusub ee crystal. Badeecadahayadu waxay u adeegaan qalabka elektarooniga ah, elektiroonigga macaamiisha, iyo militariga. Waxaan bixinaa qaybaha indhaha ee Sapphire, daboolka muraayadda taleefanka gacanta, Ceramics, LT, Silicon Carbide SIC, Quartz, iyo maraqyada crystal semiconductor. Iyada oo leh khibrad xirfad leh iyo qalab-goynta, waxaan ku fiicanahay habaynta badeecada aan caadiga ahayn, annagoo higsanayna inaan noqono hormuudka agabka optoelectronic shirkad farsamo sare leh.