Gacan/Gacan Fargeeto dhoobada Silicon Carbide

Jaantus faahfaahsan

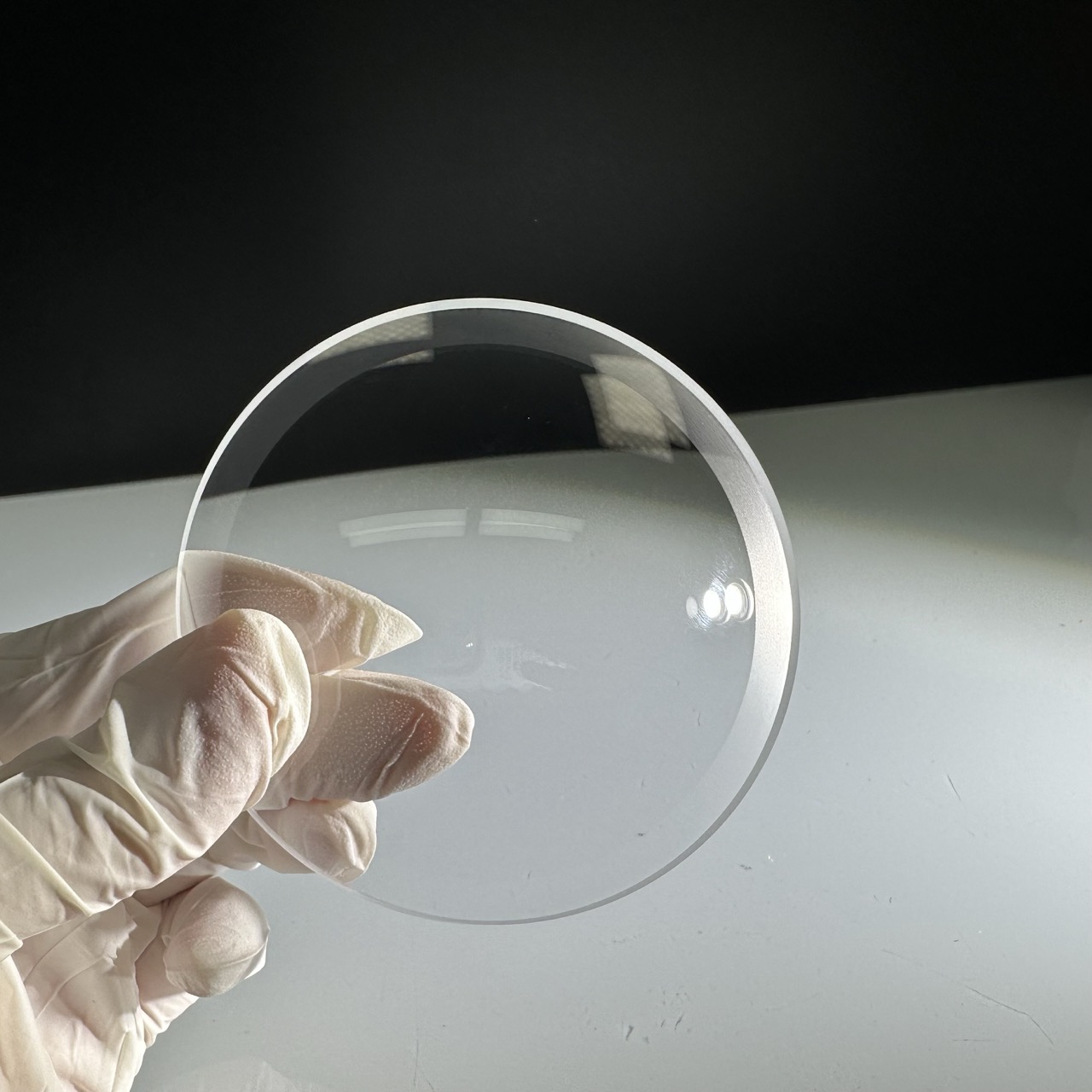

Soo bandhigida Fargeeto dhoobada ah ee Silicon Carbide Gacan/Gacan

TheGacan/Gacan Fargeeto dhoobada Silicon Carbidewaa qayb maarayn horumarsan oo loo sameeyay habab otomaatig ah oo sax ah, gaar ahaan kuwa semiconductor iyo warshadaha indhaha. Qaybtani waxa ay leedahay nakhshad gaar ah oo U-qaab ah oo loo habeeyay maaraynta waferka, iyada oo la hubinayo labadaba awoodda farsamada iyo saxnaanta cabbirka ee xaaladaha deegaanka ee aadka u daran. Laga sameeyay dhoobada silikoon carbide ee nadiifka sare ah,gacan/gacan fargeetowaxay keentaa qallafsanaan gaar ah, degenaansho kulayleed, iyo iska caabin kiimikaad.

Maaddaama aaladaha semiconductor-ku ay u xuubsiibtaan dhanka joomatariyada wanaagsan iyo dulqaadka adag, baahida qaybaha aan wasakhda lahayn iyo qaybaha kulaylka leh ayaa noqda mid muhiim ah. TheGacan/Gacan Fargeeto dhoobada Silicon Carbidela kulma caqabadan isagoo siinaya jiil yar, sagxad aad u siman, iyo qaabdhismeed adag. Haddi ay ahaan lahayd gaadiidka waferka, meelaynta substrate-ka, ama madaxa qalabka robotka, qaybtan waxa loo farsameeyay isku halaynta iyo cimri dhererka.

Sababaha muhiimka ah ee tan loo dooranayoGacan/Gacan Fargeeto dhoobada Silicon Carbidewaxaa ka mid ah:

-

Balaadhinta kulaylka ugu yar ee saxnaanta cabbirka

-

Adkeysiga sare ee nolosha adeegga dheer

-

Iska caabbinta asiidhka, alkalis, iyo gaaska falcelinta

-

Waafaqsanaanta deegaanka ISO Class 1 ee qolka nadiifka ah

Mabda'a Wax-soo-saarka ee Gacan/Gacanta Fargeetada Silicon Carbide

TheGacan/Gacan Fargeeto dhoobada Silicon Carbidewaxaa lagu soo saaray hab si heer sare ah loo xakameeyey socodka shaqada ee farsamaynta dhoobada oo loogu talagalay in lagu hubiyo sifooyinka agabka sare iyo joogteynta cabbirka.

1. Diyaarinta budada

Nidaamku wuxuu ku bilaabmayaa xulashada budada carbide silicon ultra-fine. Budadaan waxaa lagu qasaa qalabyada wax lagu xiro si loo fududeeyo cufnaanta iyo cufnaanta. Tan awgeedgacan/gacan fargeeto, β-SiC ama α-SiC budada waxaa loo isticmaalaa si loo hubiyo adkaanta iyo adkaanta labadaba.

2. Qaabaynta iyo Horumarinta

Iyada oo ku xidhan kakanaanta eegacan/gacan fargeetonaqshadeynta, qaybta waxaa loo qaabeeyey iyadoo la isticmaalayo riixid isostatic, qaabaynta duritaanka, ama shubista silbashada. Tani waxay u oggolaaneysaa joomatari adag iyo qaab-dhismeedyada derbi-dhuuban, oo muhiim u ah dabeecadda khafiifka ahGacan/Gacan Fargeeto dhoobada Silicon Carbide.

3. Heerkulka Sare ee Sintering

Sintering waxaa lagu sameeyaa heerkul ka sarreeya 2000 ° C ee vacuum ama jawiga argon. Marxaladani waxay jidhka cagaaran u beddeshaa qayb dhoobo ah oo cufan. The sintaygacan/gacan fargeetowaxa uu gaadhaa cufnaanta aragtida dhow, isaga oo siinaya sifooyin farsamo iyo kulayl aad u wanaagsan.

4. Machining sax ah

Ka-dib-u-qaadista, eeGacan/Gacan Fargeeto dhoobada Silicon Carbidemaro shiidi dheeman iyo mashiinka CNC. Tani waxay hubinaysaa fidsanaanta gudaha ± 0.01 mm waxayna u oggolaanaysaa in lagu daro godadka korka iyo helitaanka sifooyinka muhiimka u ah rakibaadda nidaamyada otomatiga ah.

5. Dhamaystirka dusha sare

Tooshka waxay yaraynaysaa qallafsanaanta dusha sare (Ra <0.02 μm), lama huraan u ah dhimista jiilka qaybsan. Dahaarka CVD Ikhtiyaarka ah ayaa lagu dabaqi karaa si loo hagaajiyo caabbinta balaasmaha ama lagu daro shaqeynta sida dabeecadda ka-hortagga ah.

Inta lagu jiro nidaamkan, borotokoolka ilaalinta tayada ayaa lagu dabaqaa si loo dammaanad qaadoGacan/Gacan Fargeeto dhoobada Silicon CarbideWaxay u qabataa si la isku halleyn karo codsiyada ugu xasaasisan.

Halbeegyada Gacanta/Gacanta Fargeetada Silicon Carbide

| Tilmaamaha ugu Muhiimsan ee Dahaarka CVD-SIC | ||

| Guryaha SiC-CVD | ||

| Dhismaha Crystal | FCC β wejiga | |

| Cufnaanta | g/cm³ | 3.21 |

| Adag | Vickers adag | 2500 |

| Cabirka Hadhuudhka | μm | 2 ~ 10 |

| Nadiifnimada Kiimikada | % | 99.99995 |

| Awoodda kulaylka | J·k-1 ·K-1 | 640 |

| Heerkulka Sublimation | ℃ | 2700 |

| Xoogga Felexural | MPa (RT 4-dhibcood) | 415 |

| Dhallinta Modul | Gpa (4pt laab, 1300 ℃) | 430 |

| Balaadhinta kulaylka (CTE) | 10-6K-1 | 4.5 |

| Dhaqdhaqaaqa kulaylka | (W/mK) | 300 |

Codsiyada Gacan/Gacda Fargeeto dhoobada Silicon Carbide

TheGacan/Gacan Fargeeto dhoobada Silicon Carbidesi weyn ayaa looga isticmaalaa guud ahaan warshadaha halkaas oo nadiif sare, xasilooni, iyo saxnaanta makaanikada ay lama huraan yihiin. Kuwaas waxaa ka mid ah:

1. Wax-soo-saarka Semiconductor

Samaynta semiconductor,Gacan/Gacan Fargeeto dhoobada Silicon Carbidewaxaa loo isticmaalaa in lagu qaado waferrada silikoon gudaha agabka habsocodka sida qolalka xargaha, nidaamyada meel dhigista, iyo qalabka kormeerka. Iska caabbinta kulaylka iyo saxnaanta cabbirkeeda ayaa ka dhigaysa mid ku habboon in la yareeyo khalkhalka waferka iyo wasakhda.

2. Soo saarista Gudida Bandhiga

In wax soo saarka OLED iyo LCD, kagacan/gacan fargeetowaxaa lagu dabaqaa hab-soo-saar-iyo-meel, halkaas oo ay ka qabato muraayadaha jilicsan ee jilicsan. Cufkeeda hoose iyo qallafsanaantiisa sare waxay awood u siinaysaa dhaqdhaqaaq degdeg ah oo deggan iyada oo aan gariir ama leexin.

3. Nidaamyada indhaha iyo sawir-qaadista

Si toos ah iyo meelaynta muraayadaha, muraayadaha, ama chips photonic, ahGacan/Gacan Fargeeto dhoobada Silicon Carbidewaxay bixisaa taageero bilaa gariir ah, oo muhiim u ah habaynta laysarka iyo codsiyada saxda ah ee metrology.

4. Aerospace & Nidaamyada Vacuum

Nidaamyada indhaha ee hawada sare iyo aaladaha faakuumka, qaybtaan qaab dhismeedka aan magnetka ahayn, ee daxalka u adkaysta waxay hubisaa xasilloonida muddada dheer. Thegacan/gacan fargeetoWaxa kale oo uu ku shaqayn karaa vacuum ultra-high (UHV) iyada oo aan la saarin.

Dhammaan dhinacyadan, theGacan/Gacan Fargeeto dhoobada Silicon Carbidewuxuu ka sarreeyaa beddelka biraha dhaqameed ama polymer-ka ee isku halaynta, nadaafadda, iyo nolosha adeegga.

FAQ ee Gacan/Gacda Fargeeto dhoobada Silicon Carbide

Q1: Waa maxay cabbirrada wafer-ka ay taageerto Fargeeto Gacan/Gacanta Silicon Carbide Ceramic Fork?

Thegacan/gacan fargeetowaxaa loo habeyn karaa si loo taageero 150 mm, 200 mm, iyo 300 mm wafers. Dhererka fargeetada, ballaca cududda, iyo qaababka daloolku waxa lagu habayn karaa si ay ugu habboonaato goobtaada gaarka ah ee otomaatiga ah.

Q2: Gacmaha/Gacanta ee Silicon-Carbide Ceramic Ceramic ma ku habboon tahay nidaamyada faakuumka?

Haa Thegacan/gacan fargeetowuxuu ku habboon yahay nidaamyada faakuumka hooseeya iyo ultra-sare labadaba. Waxay leedahay heerar gaas-soo-saar yar mana sii daayo qaybo ka mid ah, taasoo ka dhigaysa mid ku habboon qolalka nadiifka ah iyo bay'adaha faakuumka.

Q3: Ma ku dari karaa daahan ama wax ka beddelka dusha sare ee gacanta/gacanta fargeetada?

Hubaal. TheGacan/Gacan Fargeeto dhoobada Silicon Carbidewaxaa lagu dahaadhay karaa CVD-SiC, kaarboon, ama lakabyo oxide si kor loogu qaado caabbinta balaasmaha, sifooyinka anti-static, ama engegnaanta dusha.

Q4: Sidee loo xaqiijiyaa tayada gacanta fargeetada?

Mid walbaGacan/Gacan Fargeeto dhoobada Silicon Carbidewuxuu maraa kormeerka cabbirka iyadoo la adeegsanayo CMM iyo qalabka mitirka laysarka. Tayada dusha sare waxaa lagu qiimeeyaa SEM iyo profilometry aan lala xiriirin si loo buuxiyo heerarka ISO iyo SEMI.

Q5: Waa maxay wakhtiga hogaaminta ee amarrada gacanta/fargeetada gaarka ah?

Waqtiga ledhku wuxuu caadi ahaan u dhexeeyaa 3 ilaa 5 toddobaad iyadoo ku xidhan kakanaanta iyo tirada. Samaynta degdega ah ayaa diyaar u ah codsiyada degdega ah.

FAQ-yadan waxay ujeedadoodu tahay inay caawiyaan injineerada iyo kooxaha wax soo iibsiga inay fahmaan awoodaha iyo fursadaha jira marka la dooranayoGacan/Gacan Fargeeto dhoobada Silicon Carbide.

Annaga

XKH waxay ku takhasustay horumarinta tignoolajiyada sare, wax soo saarka, iyo iibinta muraayadaha indhaha ee gaarka ah iyo agabka cusub ee crystal. Badeecadahayadu waxay u adeegaan qalabka elektarooniga ah, elektiroonigga macaamiisha, iyo militariga. Waxaan bixinaa qaybaha indhaha ee Sapphire, daboolka muraayadda taleefanka gacanta, Ceramics, LT, Silicon Carbide SIC, Quartz, iyo maraqyada crystal semiconductor. Iyada oo leh khibrad xirfad leh iyo qalab-goynta, waxaan ku fiicanahay habaynta badeecada aan caadiga ahayn, annagoo higsanayna inaan noqono hormuudka agabka optoelectronic shirkad farsamo sare leh.