SiCOI wafer 4inch 6inch HPSI SiC SiO2 Si qaabdhismeedka hoosaadka

Qaab dhismeedka waferka SiCOI

HPB (Bondeynta Waxqabadka Sare) BIC (Bonded Integrated Circuit) iyo SOD (Silicon-on-Diamond ama Silicon-on-Insulator-like technology). Waxaa ka mid ah:

Hababka Waxqabadka:

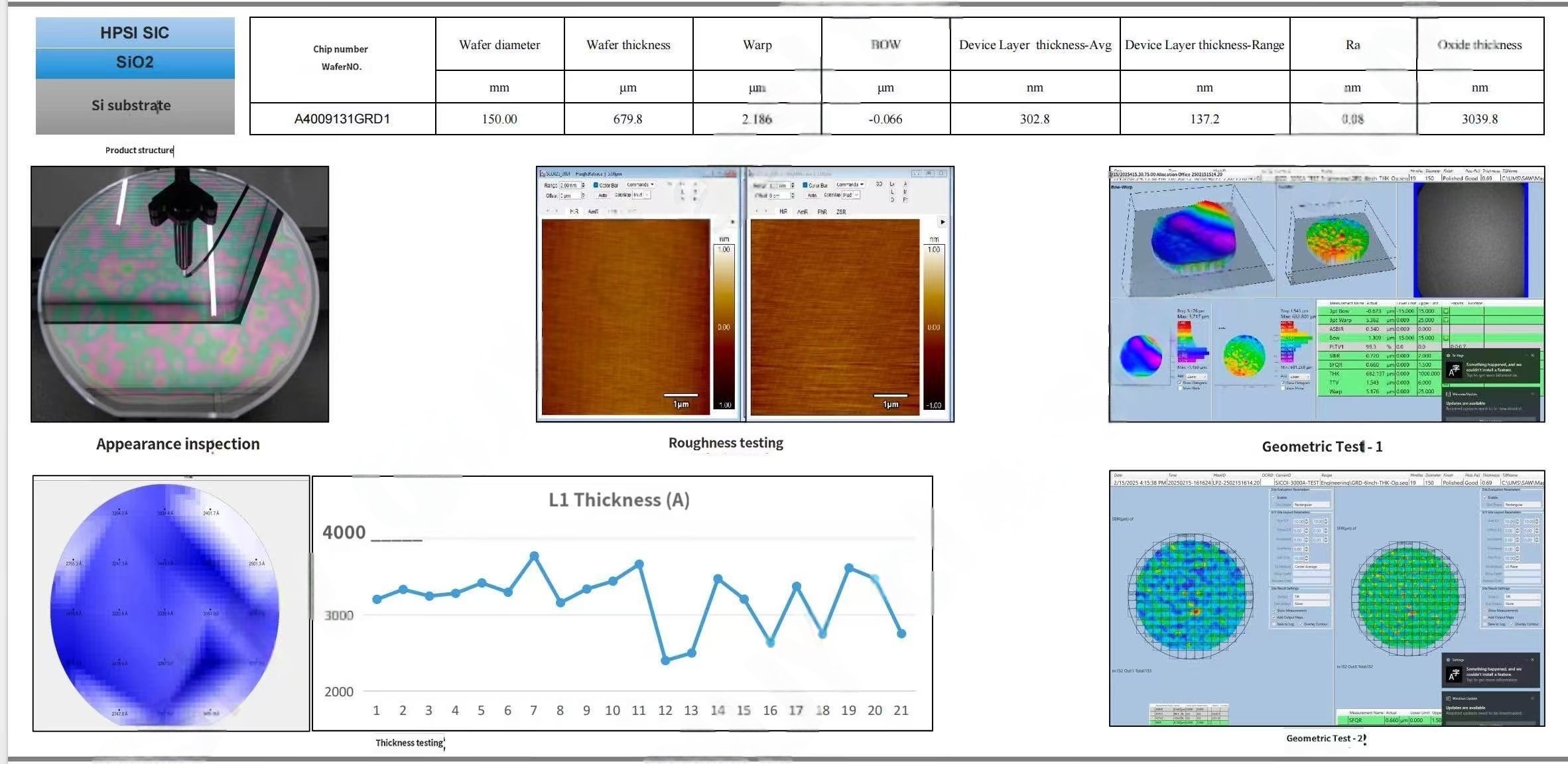

Waxay taxdaa cabbirrada sida saxnaanta, noocyada khaladka (tusaale, "Ma jiro qalad," "Masaafada Qiimaha"), iyo cabbirada dhumucda (tusaale, "Lakabka Tooska ah/kg").

Jadwal leh qiyam nambareed (laga yaabo inuu tijaabo yahay ama cabbiraadda habka) ee hoos yimaada cinwaannada sida "ADDR/SYGBDT," "10/0," iwm.

Xogta Dhumucda lakabka:

Gelitaanno badan oo soo noqnoqda oo lagu calaamadeeyay "L1 Dhumucdiisuna (A)" ilaa "L270 Dhumucdiisuna (A)" (laga yaabaa in Ångströms, 1 Å = 0.1 nm).

Waxay soo jeedinaysaa qaab dhismeed dhowr lakab ah oo leh kontorool dhumuc gaar ah oo lakab kasta ah, oo caadi ku ah wafers-ka sare ee semiconductor.

Qaabdhismeedka Wafer ee SiCOI

SiCOI (Silicon Carbide on Insulator) waa qaab dhismeed gaar ah oo wafer ah oo isku daraya silikoon carbide (SiC) oo leh lakab dahaar ah, oo la mid ah SOI (Silicon-on-Insulator) laakiin loo habeeyay codsiyada heerkulka sare/kulka sare. Tilmaamaha muhiimka ah:

Lakabka Halabuurka:

Lakabka sare: Silicon Carbide-kaliya (SiC) ee dhaqdhaqaaqa elektaroonigga sare iyo xasilloonida kulaylka.

Insulator la aasay: Caadi ahaan SiO₂ (oxide) ama dheeman (SOD) si loo yareeyo awoodda dulin loona hagaajiyo go'doominta.

Substrate-ka saldhigga: Silikoon ama polycrystalline SiC ee taageerada farsamada

Guryaha wafer ee SiCOI

Guryaha Korontada Wide Bandgap (3.2 eV for 4H-SiC): Waxay sahlaysaa korantada burburka sare (> 10 × ka sarraysa silikon) .Waxay yaraynaysaa qulqulka qulqulka, hagaajinta waxtarka qalabka korontada.

Dhaqdhaqaaqa Sare ee Electron:~ 900 cm²/V·s (4H-SiC) vs. ~ 1,400 cm²/V·s (Si), laakiin waxqabadka garoonka sare ka wanaagsan.

Iska caabin Hoose:SiCOI-ku-saleysan transistor-ku (tusaale, MOSFETs) waxay muujinayaan khasaaraha kadhalanka hoose.

Dahaarka heersare ah:Lakabka dheemanka ah ee la aasay (SiO₂) ama lakabka dheeman wuxuu yareeyaa awoodda dulin iyo hadal isdhaafsi.

- Guryaha kulaylkaDhaqdhaqaaqa Kulaylka Sare: SiC (~ 490 W/m·K ee 4H-SiC) vs. Si (~ 150 W/m·K)

Deganaanshaha kulaylka:Wuxuu u shaqeeyaa si la isku halleyn karo>300°C (marka loo eego ~150°C ee silikoon) .Waxay yaraynaysaa shuruudaha qaboojinta ee korantada korantada.

3. Guryaha Makaanikada & KiimikadaAdag aad u daran (~ 9.5 Mohs): Waxay iska caabisaa xidhashada, taasoo ka dhigaysa SiCOI mid u adkaysata bay'adaha adag.

Firfircoonida Kiimikada:Waxay u adkaysataa oksaydhka iyo daxalka, xitaa xaaladaha acidic/alkaline.

Balaadhinta kulaylka Hoose:Si fiican ugu dhigma qalabka kale ee heerkulka sare leh (tusaale, GaN).

4. Faa'iidooyinka Dhismaha (marka la barbar dhigo. Bulk SiC ama SOI)

Khasaaraha Substrate-ka oo la dhimay:Lakabka dahaadhku wuxuu ka hortagayaa daadinta hadda ee substrate-ka.

Waxqabadka RF ee la hagaajiyay:Awoodda hoose ee dulinku waxa ay saamaxdaa beddelaad degdeg ah (oo waxtar u leh 5G/mmWave).

Naqshad dabacsan:Lakabka sare ee khafiifka ah ee SiC wuxuu u oggolaanayaa in la hagaajiyo cabbirida qalabka (tusaale, kanaalada aadka u dhuuban ee transistor-ka).

Isbarbardhigga SOI & Bulk SiC

| Hanti | SiCOI | SOI (Si/SiO₂/Si) | SiC badan |

| Bandgap | 3.2 eV (SiC) | 1.1 eV (Si) | 3.2 eV (SiC) |

| Habdhaqanka kulaylka | Sare (SiC + dheeman) | Hooseeyo (SiO₂ waxay xaddidaysaa socodka kulaylka) | Sare (SiC kaliya) |

| Burburinta Voltage | Aad u Sareeya | Dhexdhexaad | Aad u Sareeya |

| Qiimaha | Sareeye | Hoose | Ugu sarreeya (SiC saafi ah) |

Codsiyada wafer ee SiCOI

Korantada Korontada

Waferrada SiCOI waxaa si weyn loogu adeegsadaa aaladaha korantada sare iyo kuwa awoodda sare leh sida MOSFETs, Schottky diodes, iyo furayaasha korantada. Bannaanka ballaaran iyo koronta jabinta sare ee SiC waxay awood u siineysaa beddelaad awood hufan leh oo leh khasaare yar iyo waxqabadka kulaylka oo la xoojiyey.

Aaladaha Soo noqnoqda Raadiyaha (RF).

Lakabka dahaadhka ah ee waferrada SiCOI waxa ay yaraynaysaa awoodda dulinka, taas oo ka dhigaysa iyaga oo ku habboon transistor-ka soo noqnoqonaya iyo cod-weyneyaasha loo isticmaalo isgaadhsiinta, radar, iyo teknoolajiyada 5G.

Nidaamyada Makaanikada Microelectromechanical (MEMS)

Wafers-yada SiCOI waxay bixiyaan madal adag oo lagu soo saaro dareemayaasha MEMS iyo hawl-wadeennada si la isku halleyn karo ugu shaqeeya bay'ad adag taasoo ay ugu wacan tahay la'aanta kiimikada SiC iyo xoogga farsamada.

Elektrooniga Heerkulka Sare

SiCOI waxay awood u siisaa qalabka elektiroonigga ah ee ilaaliya waxqabadka iyo isku halaynta heerkulka sare, ka faa'iidaysiga baabuurta, hawada hawada, iyo codsiyada warshadaha halkaasoo aaladaha silikoon ee caadiga ah ay ku fashilmaan.

Aaladaha Photonic iyo Optoelectronic

Isku darka sifooyinka indhaha ee SiC iyo lakabka dahaadhku waxay fududeeyaan is dhexgalka wareegyada sawir-qaadista iyo maaraynta kulaylka ee la xoojiyey.

Qalabka Elektrooniga ah ee Shucaaca Adag

Sababtoo ah dulqaadka shucaaca ee dabiiciga ah ee SiC, waferrada SiCOI waxay ku fiican yihiin meelaha bannaan iyo codsiyada nukliyeerka ee u baahan aaladaha u adkeysanaya jawiga shucaaca sare.

SiCOI wafer's Q&A

Q1: Waa maxay waferka SiCOI?

A: SiCOI waxay u taagan tahay Silicon Carbide-on-Insulator. Waa qaab dhismeedka wafer semiconductor halkaas oo lakabka khafiifka ah ee silikoon carbide (SiC) uu ku xidhan yahay lakabka dahaaran (sida badan silikoon dioxide, SiO₂), kaas oo ay taageerto substrate silikoon. Qaab dhismeedkani wuxuu isku daraa sifooyinka wanaagsan ee SiC iyo go'doominta korantada ee daaha.

Q2: Waa maxay faa'iidooyinka ugu muhiimsan ee wafers SiCOI?

J: Faa'iidooyinka ugu muhiimsan waxaa ka mid ah danab burbursan oo sarreeya, bandgap ballaaran, kulaylka kuleylka aadka u wanaagsan, qallafsanaanta farsamada sare, iyo hoos u dhigista awoodda dulin iyada oo ay ugu wacan tahay lakabka daboolka. Tani waxay keenaysaa hagaajinta waxqabadka qalabka, hufnaanta, iyo isku halaynta.

Q3: Waa maxay codsiyada caadiga ah ee waferrada SiCOI?

J: Waxaa loo isticmaalaa korantada elektiroonigga ah, aaladaha RF-sare ee soo noqnoqda, dareemayaasha MEMS, qalabka elektiroonigga ah ee heerkulka sarreeya, aaladaha sawir-qaadista, iyo qalabka elektarooniga ah ee shucaaca adag.

Jaantus faahfaahsan