SICOI (Silicon Carbide on Insulator) Wafers SiC Film on Silicon

Jaantus faahfaahsan

Soo bandhigida Silicon Carbide on Insulator (SICOI) wafers

Silicon Carbide on Insulator (SICOI) wafers waa jiilka soo socda ee semiconductor substrates kaas oo isku dara sifooyinka sare ee jirka iyo elektiroonigga ah ee Silicon carbide (SiC) oo leh sifooyinka go'doominta korantada ee muuqda ee lakabka daboolka, sida silicon dioxide (SiO₂) ama silicon nitride (Si₃N₄). Waferka caadiga ah ee SICOI wuxuu ka kooban yahay lakabka SiC ee epitaxial dhuuban, filim dhexdhexaad ah, iyo substrate saldhig taageero, kaas oo noqon kara silikoon ama SiC.

Qaab-dhismeedkan isku-dhafan waxa loo habeeyey si uu u daboolo baahida adag ee qalabka elektarooniga ah ee awoodda-sare leh,-soo noqnoqda, iyo kulaylka sarreeya. Marka lagu daro lakabka dahaarka, waferrada SICOI waxay yareeyaan awoodda dulin waxayna xakameeyaan qulqulka qulqulka, si loo hubiyo dhaqdhaqaaqyo hawleed oo sarreeya, hufnaan wanaagsan, iyo hagaajinta maamulka kulaylka. Faa'iidooyinkani waxay ka dhigayaan kuwo aad u qiimo badan qaybaha sida baabuurta korontada, kaabayaasha isgaarsiinta 5G, nidaamyada hawada sare, qalabka elektiroonigga ah ee RF, iyo tignoolajiyada dareemayaasha MEMS.

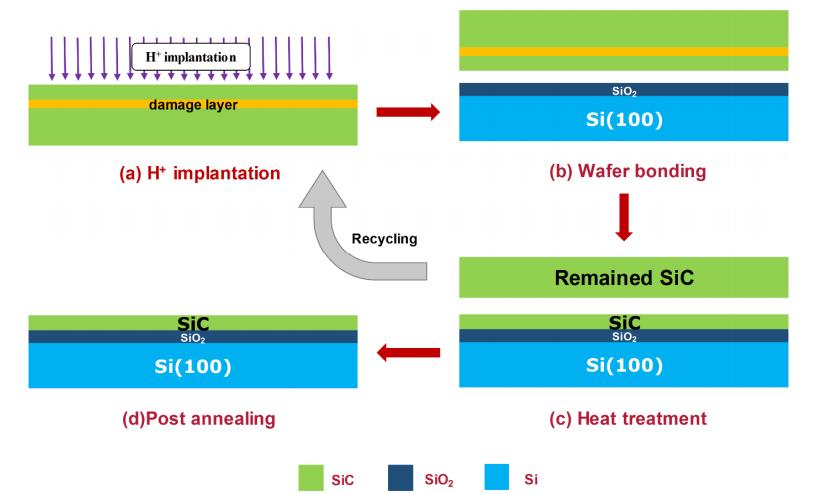

Mabaadi'da Wax-soo-saarka ee SICOI Wafers

SICOI (Silicon Carbide on Insulator) waferrada waxaa lagu soo saaray horumarsanisku xidhka wafer iyo habka khafiifinta:

-

Kobaca Substrate-ka SiC- Wafer SiC ah oo hal-crystal ah oo tayo sare leh (4H/6H) ayaa loo diyaariyey sidii walxaha ku-deeqaha.

-

Dhigista Lakabka Dahaarka- Filim dahaar ah (SiO₂ ama Si₃N₄) ayaa lagu sameeyay wafer-side (Si ama SiC).

-

Wafer Bonding- Waferka SiC iyo maraqa qaadaha waxa ay ku xidhan yihiin heerkul sare ama caawimada balaasmaha.

-

Khafiifinta & Toosinta- Waferka ku-deeqaha SiC waa la khafiifiyey ilaa dhowr mikromitir oo la sifeeyey si loo gaaro meel siman oo siman.

-

Kormeerka ugu dambeeya- Waferka SICOI ee la dhammaystiray waxaa lagu tijaabiyay lebbiska dhumucda, qallafsanaanta dusha sare, iyo waxqabadka dahaarka.

Habkan, alakabka SiC oo khafiif ah oo firfircoonoo leh sifooyin koronto oo heer sare ah iyo heerkulbeeg ah ayaa lagu daraa filim dahaaran iyo substrate taageero, abuurista madal wax qabad heersare ah oo loogu talagalay awooda jiilka soo socda iyo aaladaha RF.

Faa'iidooyinka Muhiimka ah ee Waferrada SICOI

| Qaybta Tilmaamaha | Tilmaamaha Farsamada | Faa'iidooyinka Muhiimka ah |

|---|---|---|

| Dhismaha Qalabka | 4H/6H-SiC lakabka firfircoon + filim dahaarka (SiO₂/Si₃N₄) + Si ama SiC side | Wuxuu gaaraa go'doomin koronto oo xoogan, wuxuu yareeyaa faragelinta dulin |

| Guryaha Korontada | Awood burbur sare leh (> 3 MV/cm), lumis koronto yar | Loo habeeyay hawlgal koronto-sare iyo mid-sare |

| Guryaha kulaylka | Dhaqdhaqaaqa kulaylka ilaa 4.9 W/cm · K, deggan oo ka sarreeya 500°C | Kuleyl wax ku ool ah oo baabi'iya, wax qabad heer sare ah oo ka hooseeya culeysyada kulaylka adag |

| Guryaha Makaanikada | Adag aad u daran (Mohs 9.5), iskudar hoose ee ballaarinta kulaylka | Si adag uga soo horjeeda diiqada, waxay kordhisaa cimriga aaladda |

| Tayada dusha sare | Oogada aadka u jilicsan (Ra <0.2 nm) | Waxay kor u qaadaa epitaxy-ka aan cillad lahayn iyo samaynta aaladda la isku halayn karo |

| Dahaarka | Iska caabin>10¹⁴ Ω·cm, dareere hoose | Hawlgal lagu kalsoonaan karo ee RF iyo codsiyada go'doominta korantada sare |

| Cabbirka & Habaynta | Lagu heli karo qaababka 4, 6, iyo 8-inch; Dhumucda SiC 1-100 μm; dahaarka 0.1-10 μm | Naqshad dabacsan oo loogu talagalay shuruudaha codsiyada kala duwan |

Aagagga Codsiga Muhiimka ah

| Qaybta Codsiga | Kiisaska Isticmaalka Caadiga ah | Faa'iidooyinka Waxqabadka |

|---|---|---|

| Korantada Korontada | EV rogos, saldhigyada dallaca, qalabka korontada | Danab burbursan oo sarreeya, luminta beddelka oo yaraatay |

| RF & 5G | Cod-weyneyaasha awoodda saldhigga saldhigga, qaybaha milimitirka-mawjada | Ku dulin yar, waxay taageertaa hawlgallada kala duwan ee GHz |

| Dareemayaasha MEMS | Dareemaha cadaadiska deegaanka ee adag, MEMS-navigation-grade | Deganaanshaha kulaylka sare, u adkaysta shucaaca |

| Hawada & Difaaca | Isgaarsiinta dayax-gacmeedka, cutubyada tamarta avionics | Isku hallaynta heerkulka aadka u daran iyo soo-gaadhista shucaaca |

| Smart Grid | Beddelayaasha HVDC, jebiyeyaasha wareegyada adag ee gobolka | Dahaarka sare wuxuu yareeyaa luminta tamarta |

| Optoelectronics | UV LEDs, substrates laser | Tayada crystalline sare waxay taageertaa qiiqa wax ku ool ah |

Samaynta 4H-SiCOI

Wax soo saarka 4H-SiCOI wafers waxaa lagu gaaraa iyada oo loo marayoisku xidhka wafer iyo hababka khafiifinta, awood u siinaya is-dhexgalka tayada sare leh iyo lakabyo firfircoon oo SiC ah oo aan cillad lahayn.

-

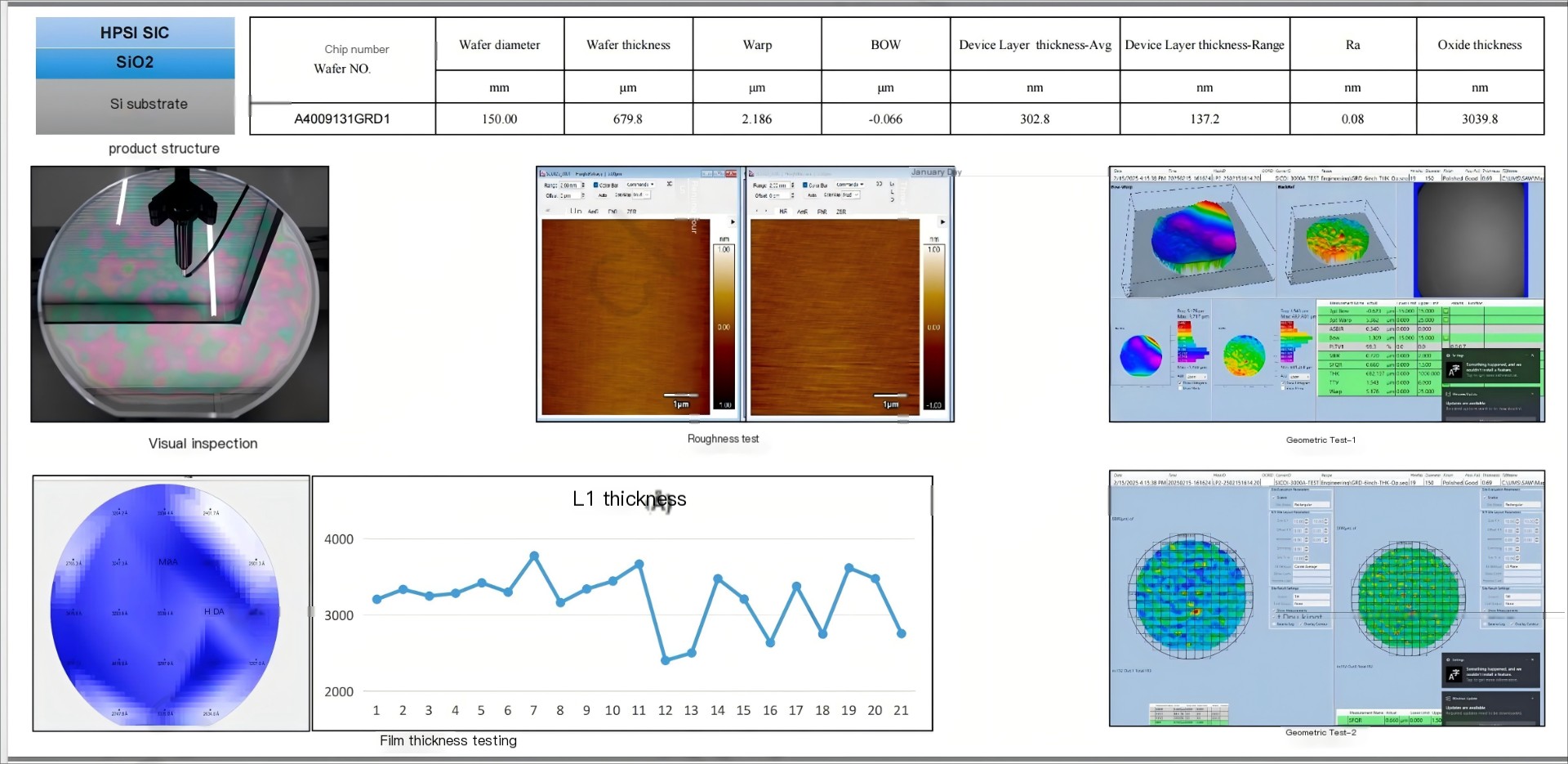

a: Jadwalka naqshadaynta qalabka 4H-SiCOI.

-

bSawirka wafer 4-inch 4H-SiCOI iyadoo la isticmaalayo isku xidhka iyo khafiifinta; aagagga cilladaysan ee la calaamadeeyay.

-

c: Sifaynta lebbiska dhumucda substrate-ka 4H-SiCOI.

-

dSawirka indhaha ee 4H-SiCOI dhinta.

-

eHabka socodka loogu talagalay soo saarista SiC microdisk resonator.

-

f: SEM ee resonator microdisk oo dhamaystiran.

-

gSEM weyn oo muujinaysa darbiga dhinaca resonator; Inset-ka AFM wuxuu muujinayaa simannaanta dusha nanoscale.

-

h: SEM-ka-talaabsan oo muujinaya dusha sare ee parabolic-qaabeeya.

FAQ on SICOI Wafers

Q1: Waa maxay faa'iidooyinkee ay leeyihiin waferrada SICOI marka loo eego maraqa dhaqameed ee SiC?

A1: Si ka duwan substrates-ka caadiga ah ee SiC, waferrada SICOI waxaa ka mid ah lakab dahaaran oo yareeya awoodda dulinka iyo qulqulka qulqulka, taasoo horseedaysa hufnaan sare, jawaab celin wanaagsan oo soo noqnoqda, iyo waxqabadka kulaylka sare.

Q2: Waa maxay cabbirrada wafer-ka ee sida caadiga ah la heli karo?

A2: Waferrada SICOI waxaa caadi ahaan loo soo saaraa 4-inch, 6-inch, iyo 8-inch formats, oo leh SiC habaysan iyo dhumucdiisuna waxay ku xiran tahay shuruudaha qalabka.

Q3: Waa kuwee warshadaha sida ugu badan uga faa'iideysta waferrada SICOI?

A3: Warshadaha muhiimka ah waxaa ka mid ah korantada korantada ee baabuurta korantada, RF electronics ee shabakadaha 5G, MEMS ee dareemayaasha hawada, iyo optoelectronics sida UV LEDs.

Q4: Sidee ayuu lakabka dahaadhka u hagaajiyaa waxqabadka qalabka?

A4: Filimka dahaarka ah (SiO₂ ama Si₃N₄) ayaa ka hortagaya daadinta hadda jirta oo waxay yaraynaysaa isdhaafsiga korantada, awood u yeelashada adkaysiga korantada sare, beddelka hufan, iyo hoos u dhaca kulaylka.

Q5: Waferrada SICOI ma ku habboon yihiin codsiyada heerkulka sare?

A5: Haa, oo leh kuleyl sare oo kuleyl ah iyo iska caabin ka baxsan 500 ° C, waferrada SICOI waxaa loogu talagalay inay si kalsooni leh ugu shaqeeyaan kulayl aad u daran iyo deegaanno adag.

Q6: Waferrada SICOI ma la beddeli karaa?

J6: Dhab ahaantii. Soo-saarayaashu waxay bixiyaan naqshado ku habboon dhumuc gaar ah, heerarka doping-ka, iyo isku-darka substrate si ay u daboolaan cilmi-baaris kala duwan iyo baahiyaha warshadaha.