4H-N HPSI SiC wafer 6H-N 6H-P 3C-N SiC Epitaxial wafer ee MOS ama SBD

Substrate SiC SiC Epi-wafer Kooban

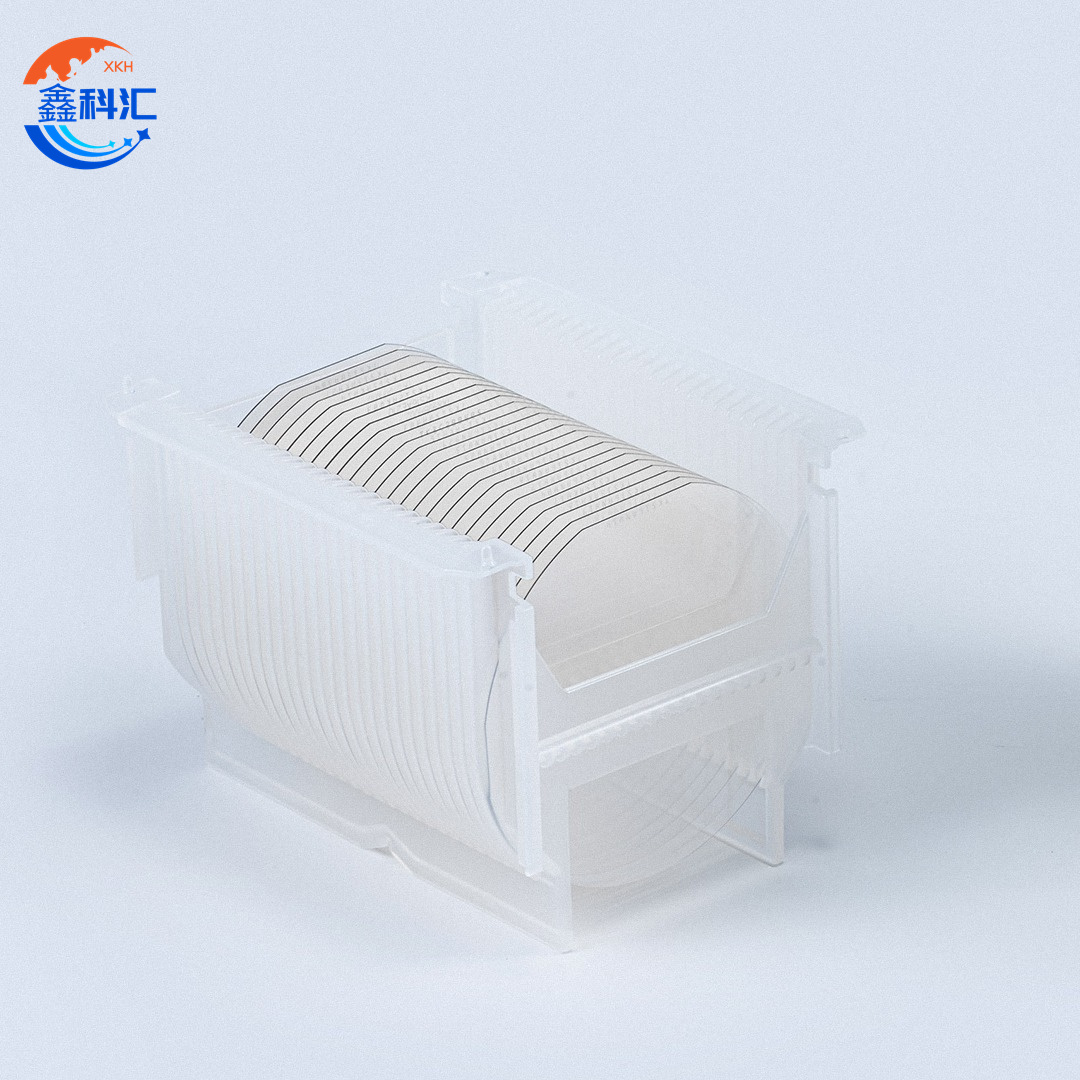

Waxaan bixinaa faylal buuxa oo tayo sare leh oo tayo sare leh oo SiC ah iyo wafers sic ah oo noocyo badan ah iyo profiles doping - oo ay ku jiraan 4H-N (n-conductive conductive), 4H-P (p-nooca conductive), 4H-HPSI (sulating-nadiif sare), iyo 6H-P (p-nooca conductive) ″ dhammaan dhexroorka iyo 6. ilaa 12 ". Marka laga soo tago substrate-yada qaawan, adeegyadayada koritaanka wafer-ka ee qiimaha lagu daray waxay bixiyaan wafers epitaxial (epi) oo leh dhumuc adag oo la xakameeyey (1-20 µm), uruurinta doping, iyo cufnaanta cilladaha.

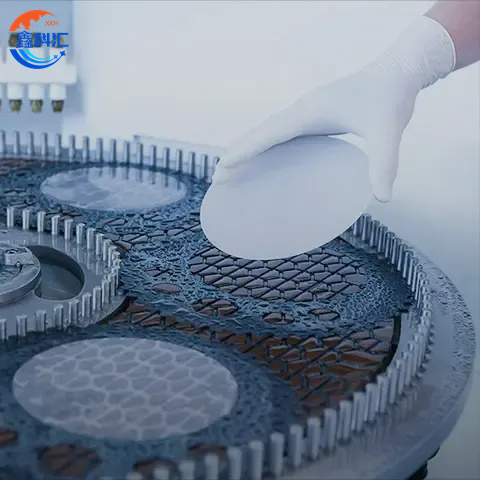

Wafer kasta iyo wafer kasta waxa la mariyaa kormeer adag oo gudaha ah (cufnaanta micropipe <0.1 cm⁻², qallafsanaanta dusha Ra <0.2 nm) iyo sifada korantada oo buuxda (CV, khariidad iska caabin ah) si loo hubiyo lebbiska kristaanka iyo waxqabadka. Haddii loo isticmaalo qalabka elektiroonigga ah ee korantada, cod-weyneyaasha RF-soo noqnoqda, ama aaladaha indhaha (LEDs, sawir-qaadayaasha), substrate-kayaga SiC iyo khadadka wax soo saarka ee epi wafer waxay keenaan kalsoonida, xasilloonida kulaylka, iyo xoogga burburka ee looga baahan yahay codsiyada maanta ugu baahida badan.

SiC Substrate 4H-N nooca guryaha iyo codsiga

-

4H-N SiC substrate Polytype (Hexagonal) Qaabdhismeedka

Baaxadda ballaaran ee ~ 3.26 eV waxay hubisaa waxqabadka korantada ee deggan iyo kuleylnimada heerkulka sare iyo xaaladaha-beeraha-korontada.

-

Substrate-ka SiCN-Nooca Doping

Daawooyinka nitrogen ee sida saxda ah loo kontoroolo waxa ay dhalisaa uruurinta qaadaha laga bilaabo 1×10¹⁶ ilaa 1×10¹⁹ cm⁻³ iyo heerkulka qolka dhaqdhaqaaqa elektarooniga ah ilaa ~900 cm²/V·s, taas oo yaraynaysa khasaaraha kadhasha.

-

Substrate-ka SiCIska caabin ballaaran & midaysan

Kala duwanaanshaha iska caabbinta la heli karo ee 0.01–10 Ω·cm iyo dhumucda wafer ee 350–650 µm oo leh ± 5% dulqaad labada doping iyo dhumucda — ku habboon samaynta aaladaha awoodda sare leh.

-

Substrate-ka SiCCufnaanta aadka u hooseeya

Cufnaanta Micropipe <0.1 cm⁻² iyo cufnaanta leexashada diyaaradda-basal <500 cm⁻², gaarsiinta> 99% dhalidda aaladda iyo hufnaanta crystal sare.

- Substrate-ka SiCHabdhaqanka Kulaylka Gaarka ah

Dhaqdhaqaaqa kulaylka ilaa ~ 370 W / m · K waxay sahlaysaa ka saarista kulaylka hufan, kor u qaadida kalsoonida qalabka iyo cufnaanta awoodda.

-

Substrate-ka SiCCodsiyada Bartilmaameedka

SiC MOSFETs, Schottky diodes, modules korantada iyo aaladaha RF ee darawalada baabuurta korantada, rogayaasha qoraxda, darawalada warshadaha, nidaamyada jiidashada, iyo suuqyada kale ee dalbanaya tamarta-electronics.

6inch 4H-N nooca SiC wafer's specification | ||

| Hanti | Wax-soo-saarka MPD eber (Grade Z) | Fasalka Dhamaystiran (D Derajada) |

| Darajo | Wax-soo-saarka MPD eber (Grade Z) | Fasalka Dhamaystiran (D Derajada) |

| Dhexroorka | 149.5 mm - 150.0 mm | 149.5 mm - 150.0 mm |

| Nooca-poly-ga | 4H | 4H |

| Dhumucda | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Hanuuninta Wafer | dhidibka ka baxsan: 4.0° dhanka <1120> 0.5° | dhidibka ka baxsan: 4.0° dhanka <1120> 0.5° |

| Cufnaanta Dheef-yar | ≤ 0.2 cm² | ≤ 15 cm² |

| iska caabin | 0.015 - 0.024 Ω·cm | 0.015 - 0.028 Ω·cm |

| Hanuuninta Flat Primary | [10-10] ± 50° | [10-10] ± 50° |

| Dhererka Guriga aasaasiga ah | 475 mm ± 2.0 mm | 475 mm ± 2.0 mm |

| Ka saarida gees | 3 mm | 3 mm |

| LTV/TIV / Qaansada / Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Qalafsanaan | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Dildilaaca Cidhifyada Iftiinka Xoogan Sare | Dhererka isugeynta ≤ 20 mm dhererka keli ah ≤ 2 mm | Dhererka isugeynta ≤ 20 mm dhererka keli ah ≤ 2 mm |

| Taarikada Hex By Iftiin Xoogan Sare | Aagga isugeynta ≤ 0.05% | Aagga isugeynta ≤ 0.1% |

| Meelo Badan Oo Iftiin Xoogan Sare leh | Aagga isugeynta ≤ 0.05% | Aagga isugeynta ≤ 3% |

| Kaarboon Muuqaal ah | Aagga isugeynta ≤ 0.05% | Aagga isugeynta ≤ 5% |

| Dusha sare ee Silikoon xoqida Iftiinka xoogga sare | Dhererka isugeynta ≤ 1 dhexroor maraq | |

| Chips-ka Cidhifyada Iftiinka Xoogga Sare | Midna lama oggola ≥ 0.2 mm ballac iyo qoto dheer | 7 waa la oggol yahay, ≤ 1 mm midkiiba |

| Kala-baxa Xadhkaha Isku-xidhka | <500 cm³ | <500 cm³ |

| Wasakhaynta Dusha Silikoon ee Iftiinka Xoogan Sare | ||

| Baakadaha | Cassette Multi-wafer ah ama Konteenarka Waferka Keliya | Cassette Multi-wafer ah ama Konteenarka Waferka Keliya |

8inch 4H-N nooca SiC wafer sifada | ||

| Hanti | Wax-soo-saarka MPD eber (Grade Z) | Fasalka Dhamaystiran (D Derajada) |

| Darajo | Wax-soo-saarka MPD eber (Grade Z) | Fasalka Dhamaystiran (D Derajada) |

| Dhexroorka | 199.5 mm - 200.0 mm | 199.5 mm - 200.0 mm |

| Nooca-poly-ga | 4H | 4H |

| Dhumucda | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Hanuuninta Wafer | 4.0° dhanka <110> ± 0.5° | 4.0° dhanka <110> ± 0.5° |

| Cufnaanta Dheef-yar | ≤ 0.2 cm² | ≤ 5 cm² |

| iska caabin | 0.015 - 0.025 Ω·cm | 0.015 - 0.028 Ω·cm |

| Hanuuninta Sharafta leh | ||

| Ka saarida gees | 3 mm | 3 mm |

| LTV/TIV / Qaansada / Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Qalafsanaan | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Dildilaaca Cidhifyada Iftiinka Xoogan Sare | Dhererka isugeynta ≤ 20 mm dhererka keli ah ≤ 2 mm | Dhererka isugeynta ≤ 20 mm dhererka keli ah ≤ 2 mm |

| Taarikada Hex By Iftiin Xoogan Sare | Aagga isugeynta ≤ 0.05% | Aagga isugeynta ≤ 0.1% |

| Meelo Badan Oo Iftiin Xoogan Sare leh | Aagga isugeynta ≤ 0.05% | Aagga isugeynta ≤ 3% |

| Kaarboon Muuqaal ah | Aagga isugeynta ≤ 0.05% | Aagga isugeynta ≤ 5% |

| Dusha sare ee Silikoon xoqida Iftiinka xoogga sare | Dhererka isugeynta ≤ 1 dhexroor maraq | |

| Chips-ka Cidhifyada Iftiinka Xoogga Sare | Midna lama oggola ≥ 0.2 mm ballac iyo qoto dheer | 7 waa la oggol yahay, ≤ 1 mm midkiiba |

| Kala-baxa Xadhkaha Isku-xidhka | <500 cm³ | <500 cm³ |

| Wasakhaynta Dusha Silikoon ee Iftiinka Xoogan Sare | ||

| Baakadaha | Cassette Multi-wafer ah ama Konteenarka Waferka Keliya | Cassette Multi-wafer ah ama Konteenarka Waferka Keliya |

4H-SiC waa wax qabad heersare ah oo loo isticmaalo korantada elektiroonigga ah, aaladaha RF, iyo codsiyada heerkulka sare. "4H" waxaa loola jeedaa qaab dhismeedka crystal, kaas oo ah laba geesood, iyo "N" waxay muujinaysaa nooca doping ah loo isticmaalo si loo hagaajiyo waxqabadka alaabta.

The4H-SiCnooca waxaa inta badan loo isticmaalaa:

Korantada Korontada:Loo isticmaalo aaladaha sida dioska, MOSFETs, iyo IGBTs ee tareennada korantada ee baabuurta, mishiinada warshadaha, iyo nidaamyada tamarta la cusboonaysiin karo.

Tignoolajiyada 5G:Baahida 5G ee qaybaha wax-ku-oolnimada sare iyo waxtarka sare leh, awoodda SiC ee ay ku maarayn karto danab sare oo ay ku shaqeyso heerkul sare ayaa ka dhigaysa mid ku habboon cod-weyneyaasha saldhigga saldhigga iyo aaladaha RF.

Nidaamyada Tamarta Cadceedda:Guryaha wax ka qabashada awooda aadka u fiican ee SiC waxay ku habboon yihiin beddelayaasha iyo beddelayaasha sawir-voltaic ah.

Baabuurta Korontada (EVs):SiC waxaa si weyn loogu isticmaalaa tareennada tamarta ee EV si loogu beddelo tamar waxtar badan leh, kuleyl hoose oo soo saara, iyo cufnaanta awoodda sare.

Substrate-ka SiC Substrate 4H Noocyada iyo codsiga nooca dahaadhka ah

Guryaha:

-

Farsamooyinka xakamaynta cufnaanta-ka-free-boobka-yar: Waxay hubisaa maqnaanshaha micropipes, hagaajinta tayada substrate-ka.

-

Farsamooyinka xakamaynta Monocrystalline: Waxay dammaanad qaadaysaa hal dhisme oo crystal ah oo loogu talagalay sifooyinka walxaha la xoojiyay.

-

Ku darida farsamooyinka xakamaynta: Waxay yaraynaysaa joogitaanka wasakhda ama ku darida, hubinta substrate saafi ah.

-

Farsamooyinka xakamaynta iska caabintaWaxay u ogolaataa xakamaynta saxda ah ee iska caabbinta korantada, taas oo muhiim u ah waxqabadka qalabka.

-

Nidaaminta wasakhda iyo farsamooyinka xakamaynta: Wuxuu nidaamiyaa oo xaddidaa soo bandhigida wasakhda si loo ilaaliyo daacadnimada substrate-ka.

-

Talaabada substrate farsamooyinka xakamaynta ballaca: Waxay siisaa kontorool sax ah oo ku saabsan ballaca tillaabada, isaga oo hubinaya joogteynta guud ahaan substrate-ka

6Inji 4H-semi SiC qeexida substrate | ||

| Hanti | Wax-soo-saarka MPD eber (Grade Z) | Fasalka Dhamaystiran (D Derajada) |

| Dhexroorka (mm) | 145 mm - 150 mm | 145 mm - 150 mm |

| Nooca-poly-ga | 4H | 4H |

| Dhumucda (um) | 500 ± 15 | 500 ± 25 |

| Hanuuninta Wafer | Dhinaca dhidibka: ± 0.0001° | Dhinaca dhidibka: ± 0.05° |

| Cufnaanta Dheef-yar | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Iska caabin (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Hanuuninta Flat Primary | (0-10)° ± 5.0° | (10-10)° ± 5.0° |

| Dhererka Guriga aasaasiga ah | Darajo | Darajo |

| Ka saarida cidhifka (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Bowl / Warp | ≤ 3µm | ≤ 3µm |

| Qalafsanaan | Polish Ra ≤ 1.5 µm | Polish Ra ≤ 1.5 µm |

| Chips-ka Cidhifyada Iftiinka Xoogga Sare | ≤20 µm | ≤ 60µm |

| Kuleylka Taarikada Iftiinka Xoogga Sare | Isugeynta ≤ 0.05% | Isugeynta ≤ 3% |

| Meelo Badan Oo Iftiin Xoogan Sare leh | Kaarboonka Muuqaalka ah ≤ 0.05% | Isugeynta ≤ 3% |

| Dusha sare ee Silikoon xoqida Iftiinka xoogga sare | ≤ 0.05% | Isugeynta ≤ 4% |

| Chips-ka Cidhifyada Iftiinka Xoogga Sare (Xajmiga) | Lama Ogolaan> 02mm Balac iyo Qoto dheer | Lama Ogolaan> 02mm Balac iyo Qoto dheer |

| Caawinta Screw Dilation | ≤ 500 µm | ≤ 500 µm |

| Wasakhaynta Dusha Silikoon ee Iftiinka Xoogan Sare | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Baakadaha | Cassette-wafer-badan ama weel wafer oo kali ah | Cassette-wafer-badan ama weel wafer oo kali ah |

4-Inch 4H-Semi Insulating SiC Substrate Caymiska

| Halbeegga | Wax-soo-saarka MPD eber (Grade Z) | Fasalka Dhamaystiran (D Derajada) |

|---|---|---|

| Guryaha Jirka | ||

| Dhexroorka | 99.5 mm - 100.0 mm | 99.5 mm - 100.0 mm |

| Nooca-poly-ga | 4H | 4H |

| Dhumucda | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Hanuuninta Wafer | Dhinaca dhidibka: <600h> 0.5° | Dhanka dhidibka: <000h> 0.5° |

| Guryaha Korontada | ||

| Cufnaanta Micropipe (MPD) | ≤1cm⁻² | ≤15cm⁻² |

| iska caabin | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Dulqaadyada joomatari | ||

| Hanuuninta Flat Primary | (0x10) ± 5.0° | (0x10) ± 5.0° |

| Dhererka Guriga aasaasiga ah | 52.5 mm ± 2.0 mm | 52.5 mm ± 2.0 mm |

| Dhererka Guriga Sare | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| Hanuuninta Guriga Sare | 90° CW oo ka yimid dabaqa Primer ± 5.0° (Si weji kor) | 90° CW oo ka yimid dabaqa Primer ± 5.0° (Si weji kor) |

| Ka saarida gees | 3 mm | 3 mm |

| LTV / TTV / Qaansada / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| Tayada dusha sare | ||

| Roughness dusha sare (Polish Ra) | ≤1 nm | ≤1 nm |

| Dusha sare (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Dildilaaca cidhifka (Iftiinka xoogga badan) | Lama ogola | Dhererka isugeynta ≥10 mm, hal dildilaac ≤2 mm |

| Cilladaha saxan saddex geesoodka ah | ≤0.05% aagga isugeynta | ≤0.1% aagga isugeynta |

| Noocyada ka mid noqoshada aagagga | Lama ogola | ≤1% aagga isugeynta |

| Kaarboon Muuqaal ah | ≤0.05% aagga isugeynta | ≤1% aagga isugeynta |

| Xoqashada dusha sare ee Silicon | Lama ogola | ≤1 dhexroorka wafer dhererka wadarta |

| Chips Edge | Midna lama oggola (≥0.2 mm ballac/ qoto dheer) | ≤5 chips (mid walba ≤1 mm) |

| Wasakhaynta Dusha Silicon | Lama cayimin | Lama cayimin |

| Baakadaha | ||

| Baakadaha | Cajalad badan oo wafer ah ama weel kaliya oo canjeero ah | Cajalad wafer badan ama |

Codsiga:

TheSiC 4H Substrate-ka-dahaaran ee Semi-Insulatingwaxaa ugu horrayn loo adeegsadaa aaladaha elegtarooniga ah ee awoodda sare leh iyo kuwa soo noqnoqonaya, gaar ahaan kuwa ku jiragoobta RF. Substrate-yadan ayaa muhiim u ah codsiyada kala duwan oo ay ku jiraannidaamyada isgaarsiinta microwave, raadaar weji lehiyoqalabka korontada ee wireless. Dhaqdhaqaaqooda kulaylka sare iyo sifooyinka korantada ee aadka u fiican ayaa ka dhigaya kuwo ku habboon dalabaadka codsiyada korontada iyo hababka isgaarsiinta.

SiC epi wafer 4H-N nooca guryaha iyo codsiga

SiC 4H-N Nooca Epi Wafer Guryaha iyo Codsiyada

Qalabka SiC 4H-N Nooca Epi Wafer:

Qalabaynta Maaddada:

SiC (Silicon Carbide): Waxaa lagu yaqaanaa adkeysigeeda aadka u sarreeya, kuleylka kuleylka sarreeya, iyo sifooyinka korantada ee aadka u wanaagsan, SiC waxay ku habboon tahay aaladaha elektiroonigga ah ee waxqabadka sarreeya.

4H-SiC Polytype: 4H-SiC polytype waxaa lagu yaqaanaa waxtarkeeda sare iyo xasilloonida codsiyada elektaroonigga ah.

Nooca N-Doping: N-nooca doping (doped with nitrogen) waxay bixisaa dhaqdhaqaaqa elektaroonigga ah ee aad u fiican, taasoo ka dhigaysa SiC ku habboon codsiyada soo noqnoqda iyo awoodda sare.

Habdhaqanka Kulaylka Sare:

Wafers-yada SiC waxay leeyihiin kuleyl heer sare ah, oo caadi ahaan u dhexeeya120–200 W/m·K, iyaga oo u oggolaanaya inay si wax ku ool ah u maareeyaan kulaylka aaladaha awoodda sare leh sida transistor-ka iyo diodeska.

Bandgap ballaaran:

Iyada oo bandgap ah3.26 eV, 4H-SiC waxay ku shaqeyn kartaa koronto sare, wareegyo, iyo heerkul marka la barbar dhigo qalabka caadiga ah ee silikon ku salaysan, taas oo ka dhigaysa mid ku habboon codsiyada waxtarka sare leh.

Guryaha Korontada:

Dhaqdhaqaaqa elektaroonigga sare ee SiC iyo dhaqdhaqaaqa ayaa ka dhigaya mid ku habboonkorontada korontada, Bixinta xawaaraha beddelka degdega ah iyo awoodda wax ka qabashada hadda iyo korantada oo sarreeya, taasoo keentay nidaamyo maareyn koronto oo hufan.

Iska caabinta Makaanikada iyo Kiimikada:

SiC waa mid ka mid ah qalabka ugu adag, labaad oo kaliya dheeman, oo aad bay u adkeysi u leh oksaydhka iyo daxalka, taas oo ka dhigaysa mid ku waaraya jawi adag.

Codsiyada SiC 4H-N Nooca Epi Wafer:

Korantada Korontada:

Wafers nooca SiC 4H-N ayaa si weyn loogu isticmaalaa gudahaMOSFET-yada awoodda, IGBTsiyodareereyaalwaayoawoodda beddeliddanidaamyada sidarogayaasha qoraxda, baabuurta korontadaiyonidaamyada kaydinta tamarta, bixinta waxqabadka la xoojiyay iyo hufnaanta tamarta.

Baabuurta Korontada (EVs):

In tareennada korantada ee baabuurta, kontaroolayaasha mootadaiyosaldhigyada dallacaadda, Wafers SiC waxay gacan ka geysataa sidii loo gaari lahaa hufnaanta batteriga, dallaca degdega ah, iyo hagaajinta waxqabadka tamarta guud sababtoo ah awoodda ay u leeyihiin inay xakameyaan awoodda sare iyo heerkulka.

Nidaamyada tamarta la cusboonaysiin karo:

Rogayaasha Qorraxda: Waferrada SiC waxaa loo isticmaalaa gudahanidaamyada tamarta qoraxdasi loogu beddelo awoodda DC ee muraayadaha qorraxda loona beddelo AC, kordhinta guud ahaan waxtarka nidaamka iyo waxqabadka.

Mashiinnada dabaysha: Tignoolajiyada SiC ayaa lagu shaqeeyaanidaamyada xakamaynta marawaxadaha dabaysha, wanaajinta koronto-dhaliyaha iyo waxtarka beddelka.

Hawada iyo Difaaca:

Waferrada SiC ayaa ku habboon in lagu isticmaaloaerospace electronicsiyocodsiyo ciidan, oo ay ku jiraannidaamyada radariyoqalabka elektarooniga ah ee dayax-gacmeedka, halkaas oo iska caabbinta shucaaca sare iyo xasilloonida kulaylku ay muhiim u yihiin.

Codsiyada Heerkulka Sare iyo Joogtada Sare:

SiC wafers ayaa aad ugu fiicanqalabka elektarooniga ah ee heerkulka sare leh, loo isticmaalomatoorada diyaaradaha, dayaxgacmeediyohababka kululaynta warshadaha, maadaama ay ku hayaan waxqabadka xaaladaha kulaylka aadka u daran. Intaa waxaa dheer, xirmooyinkooda ballaaran ayaa u oggolaanaya in lagu isticmaalo gudahacodsiyada soo noqnoqda saresidaQalabka RFiyoisgaarsiinta microwave.

| 6-inch N-nooca Epit axial specification | |||

| Halbeegga | unug | Z-MOS | |

| Nooca | Dabeecadda/Dopant | - | N-nooca / Nitrojiinka |

| Lakabka Buffer | Dhumucda Lakabka Buffer | um | 1 |

| Dulqaadashada Dhumucda lakabka Buffer | % | ± 20% | |

| Isku-xidhka Lakabka Buffer | cm-3 | 1.00E+18 | |

| Dulqaadashada Lakabka Buffer | % | ± 20% | |

| Lakabka Epi 1aad | Dhumucda lakabka Epi | um | 11.5 |

| Midaynta Dhumucda lakabka Epi | % | ± 4% | |

| Dulqaadashada Dhumucda lakabyada Epi ((Spec- Ugu badnaan, Min)/Spec) | % | ± 5% | |

| Isku-duubnida lakabka Epi | cm-3 | 1E 15~ 1E 18 | |

| Dulqaadashada Lakabka Epi | % | 6% | |

| Isku-duubnaanta Isku-duubnida lakabka Epi (σ /macnaha) | % | ≤5% | |

| Lakabka Epi Isku-duubnida <(max-min)/(max+min> | % | ≤ 10% | |

| Qaabka Waferka ee Epitaixal | Qaansada | um | ≤±20 |

| WARP | um | ≤30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤2 | |

| Tilmaamaha Guud | dhererka xaaqid | mm | ≤30mm |

| Chips Edge | - | MIDNA | |

| Qeexitaanka cilladaha | ≥97% ( Lagu cabiray 2*2, Cilladaha dilaaga ah waxaa ka mid ah: Cilladaha waxaa ka mid ah Karootada, saddex xagal | ||

| Wasakhowga birta | atamka/cm² | d f f i ≤5E10 atamka/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Xidhmada | Tilmaamaha xirxirida | pcs/sanduuqa | cajalad wafer ah oo badan ama weel maraf ah oo keliya |

| 8-inch nooca N-qeexitaanka epitaxial | |||

| Halbeegga | unug | Z-MOS | |

| Nooca | Dabeecadda/Dopant | - | N-nooca / Nitrojiinka |

| Lakabka kaydinta | Dhumucda Lakabka Buffer | um | 1 |

| Dulqaadashada Dhumucda lakabka Buffer | % | ± 20% | |

| Isku-xidhka Lakabka Buffer | cm-3 | 1.00E+18 | |

| Dulqaadashada Lakabka Buffer | % | ± 20% | |

| Lakabka Epi 1aad | Celceliska dhumucda lakabyada Epi | um | 8 ~ 12 |

| Midaynta Dhumucda lakabyada Epi (σ/ celcelis ahaan) | % | ≤2.0 | |

| Dulqaadashada Dhumucda lakabyada Epi ((Spec -Max, Min)/Spec) | % | ±6 | |

| Lakabyada Epi Celceliska Doping | cm-3 | 8E+15 ~2E+16 | |

| Epi Layers Net Doping Uniformity (σ/macnaha) | % | ≤5 | |

| Epi Layers Net DopingTolerance ((Spec-Max,) | % | ± 10.0 | |

| Qaabka Waferka ee Epitaixal | Mi )/S) Warp | um | ≤50.0 |

| Qaansada | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm×10mm) | |

| Guud ahaan Astaamaha | xoqid | - | Dhererka isugeynta≤ 1/2 dhexroorka wafer |

| Chips Edge | - | ≤2 chips, Radius kasta≤1.5mm | |

| Wasaqda Biraha Dusha sare | atamka/cm2 | ≤5E10 atamka/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Baadhitaanka cilladaysan | % | ≥ 96.0 (2X2 cilladaha waxaa ka mid ah Micropipe / godad waaweyn, Karootada, cilladaha saddex xagal, hoos u dhaca, Linear/IGSF-s, BPD) | |

| Wasaqda Biraha Dusha sare | atamka/cm2 | ≤5E10 atamka/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Xidhmada | Tilmaamaha xirxirida | - | cajalad wafer ah oo badan ama weel maraf ah oo keliya |

Su'aalaha iyo jawaabaha SiC wafer

Q1: Waa maxay faa'iidooyinka ugu muhiimsan ee isticmaalka waferrada SiC ee ku saabsan waferrada silikoon ee dhaqameed ee korontada ku shaqeeya?

A1:

Waferrada SiC waxay bixiyaan faa'iidooyin dhowr ah oo muhiim ah marka loo eego silikoon (Si) wafers-dhaqameedka korontada ku shaqeeya, oo ay ku jiraan:

Waxtarka sareSiC waxay leedahay faashad ballaadhan (3.26 eV) marka la barbar dhigo silikoon (1.1 eV), taas oo u oggolaanaysa aaladaha inay ku shaqeeyaan koronto sare, wareegyo, iyo heerkul. Tani waxay keenaysaa hoos u dhaca awoodda iyo waxtarka sare ee nidaamyada beddelka awoodda.

Dhaqdhaqaaqa Kuleylka Sare: Xakamaynta kulaylka ee SiC ayaa aad uga sarreeya kan silikoon, taas oo awood u siinaysa kulaylka wanaagsan ee codsiyada awoodda sare leh, taas oo hagaajinaysa kalsoonida iyo cimriga qalabka korontada.

Korantada Sare iyo Qabashada Hadda: Aaladaha SiC waxay xamili karaan danab sare iyo heerar hadda jira, taasoo ka dhigaysa inay ku habboon yihiin codsiyada awoodda sare leh sida baabuurta korantada, nidaamyada tamarta la cusboonaysiin karo, iyo wadista baabuurta warshadaha.

Xawaaraha beddelka degdega ah: Aaladaha SiC waxay leeyihiin awood beddelasho degdeg ah, taas oo gacan ka geysata dhimista lumitaanka tamarta iyo cabbirka nidaamka, iyaga oo ka dhigaya kuwo ku habboon codsiyada soo noqnoqda.

Q2: Waa maxay codsiyada ugu muhiimsan ee waferrada SiC ee warshadaha baabuurta?

A2:

Warshadaha baabuurta, waferrada SiC ayaa ugu horrayn lagu isticmaalaa:

Gaadiidka Korontada (EV) Tareennada KorontadaQaybaha SiC-ku-salaysan sidarogayaashaiyoMOSFET-yada awooddawanaaji hufnaanta iyo waxqabadka tareennada baabuurta korontada ku shaqeeya adiga oo awood u siinaya xawaaraha beddelka degdega ah iyo cufnaanta tamarta sare. Tani waxay keenaysaa nolosha batteriga oo dheer iyo waxqabadka guud ee baabuurka oo wanaagsan.

Dabaysha-Boardka: Aaladaha SiC waxay gacan ka geystaan hagaajinta hufnaanta nidaamyada ku dallaca guddiga iyaga oo awood u siinaya waqtiyada dallacaadda degdegga ah iyo maaraynta kulaylka wanaagsan, taas oo muhiim u ah EVs si ay u taageeraan saldhigyada awoodda sare leh.

Nidaamyada Maareynta Batteriga (BMS): Tiknoolajiyada SiC waxay hagaajinaysaa waxtarkanidaamyada maareynta batteriga, taasoo u oggolaanaysa nidaaminta korantada ka wanaagsan, maaraynta awoodda sare, iyo nolosha batteriga oo dheer.

Beddelayaasha DC-DC: Waferrada SiC waxaa loo isticmaalaa gudahabeddelayaasha DC-DCsi loogu beddelo tamarta-sare ee DC awoodda korantada yar ee DC si wax ku ool ah, taas oo muhiim u ah baabuurta korontada si ay u maareeyaan awoodda batteriga ilaa qaybaha kala duwan ee gaariga.

Waxqabadka sare ee SiC ee korantada sare, heerkulka sare, iyo hufnaanta sare waxay ka dhigaysaa lama huraan u gudubka warshadaha baabuurta ee dhaqdhaqaaqa korantada.

6inch 4H-N nooca SiC wafer's specification | ||

| Hanti | Wax-soo-saarka MPD eber (Grade Z) | Fasalka Dhamaystiran (D Derajada) |

| Darajo | Wax-soo-saarka MPD eber (Grade Z) | Fasalka Dhamaystiran (D Derajada) |

| Dhexroorka | 149.5 mm - 150.0 mm | 149.5 mm - 150.0 mm |

| Nooca-poly-ga | 4H | 4H |

| Dhumucda | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Hanuuninta Wafer | dhidibka ka baxsan: 4.0° dhanka <1120> 0.5° | dhidibka ka baxsan: 4.0° dhanka <1120> 0.5° |

| Cufnaanta Dheef-yar | ≤ 0.2 cm² | ≤ 15 cm² |

| iska caabin | 0.015 - 0.024 Ω·cm | 0.015 - 0.028 Ω·cm |

| Hanuuninta Flat Primary | [10-10] ± 50° | [10-10] ± 50° |

| Dhererka Guriga aasaasiga ah | 475 mm ± 2.0 mm | 475 mm ± 2.0 mm |

| Ka saarida gees | 3 mm | 3 mm |

| LTV/TIV / Qaansada / Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Qalafsanaan | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Dildilaaca Cidhifyada Iftiinka Xoogan Sare | Dhererka isugeynta ≤ 20 mm dhererka keli ah ≤ 2 mm | Dhererka isugeynta ≤ 20 mm dhererka keli ah ≤ 2 mm |

| Taarikada Hex By Iftiin Xoogan Sare | Aagga isugeynta ≤ 0.05% | Aagga isugeynta ≤ 0.1% |

| Meelo Badan Oo Iftiin Xoogan Sare leh | Aagga isugeynta ≤ 0.05% | Aagga isugeynta ≤ 3% |

| Kaarboon Muuqaal ah | Aagga isugeynta ≤ 0.05% | Aagga isugeynta ≤ 5% |

| Dusha sare ee Silikoon xoqida Iftiinka xoogga sare | Dhererka isugeynta ≤ 1 dhexroor maraq | |

| Chips-ka Cidhifyada Iftiinka Xoogga Sare | Midna lama oggola ≥ 0.2 mm ballac iyo qoto dheer | 7 waa la oggol yahay, ≤ 1 mm midkiiba |

| Kala-baxa Xadhkaha Isku-xidhka | <500 cm³ | <500 cm³ |

| Wasakhaynta Dusha Silikoon ee Iftiinka Xoogan Sare | ||

| Baakadaha | Cassette Multi-wafer ah ama Konteenarka Waferka Keliya | Cassette Multi-wafer ah ama Konteenarka Waferka Keliya |

8inch 4H-N nooca SiC wafer sifada | ||

| Hanti | Wax-soo-saarka MPD eber (Grade Z) | Fasalka Dhamaystiran (D Derajada) |

| Darajo | Wax-soo-saarka MPD eber (Grade Z) | Fasalka Dhamaystiran (D Derajada) |

| Dhexroorka | 199.5 mm - 200.0 mm | 199.5 mm - 200.0 mm |

| Nooca-poly-ga | 4H | 4H |

| Dhumucda | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Hanuuninta Wafer | 4.0° dhanka <110> ± 0.5° | 4.0° dhanka <110> ± 0.5° |

| Cufnaanta Dheef-yar | ≤ 0.2 cm² | ≤ 5 cm² |

| iska caabin | 0.015 - 0.025 Ω·cm | 0.015 - 0.028 Ω·cm |

| Hanuuninta Sharafta leh | ||

| Ka saarida gees | 3 mm | 3 mm |

| LTV/TIV / Qaansada / Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Qalafsanaan | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Dildilaaca Cidhifyada Iftiinka Xoogan Sare | Dhererka isugeynta ≤ 20 mm dhererka keli ah ≤ 2 mm | Dhererka isugeynta ≤ 20 mm dhererka keli ah ≤ 2 mm |

| Taarikada Hex By Iftiin Xoogan Sare | Aagga isugeynta ≤ 0.05% | Aagga isugeynta ≤ 0.1% |

| Meelo Badan Oo Iftiin Xoogan Sare leh | Aagga isugeynta ≤ 0.05% | Aagga isugeynta ≤ 3% |

| Kaarboon Muuqaal ah | Aagga isugeynta ≤ 0.05% | Aagga isugeynta ≤ 5% |

| Dusha sare ee Silikoon xoqida Iftiinka xoogga sare | Dhererka isugeynta ≤ 1 dhexroor maraq | |

| Chips-ka Cidhifyada Iftiinka Xoogga Sare | Midna lama oggola ≥ 0.2 mm ballac iyo qoto dheer | 7 waa la oggol yahay, ≤ 1 mm midkiiba |

| Kala-baxa Xadhkaha Isku-xidhka | <500 cm³ | <500 cm³ |

| Wasakhaynta Dusha Silikoon ee Iftiinka Xoogan Sare | ||

| Baakadaha | Cassette Multi-wafer ah ama Konteenarka Waferka Keliya | Cassette Multi-wafer ah ama Konteenarka Waferka Keliya |

6Inji 4H-semi SiC qeexida substrate | ||

| Hanti | Wax-soo-saarka MPD eber (Grade Z) | Fasalka Dhamaystiran (D Derajada) |

| Dhexroorka (mm) | 145 mm - 150 mm | 145 mm - 150 mm |

| Nooca-poly-ga | 4H | 4H |

| Dhumucda (um) | 500 ± 15 | 500 ± 25 |

| Hanuuninta Wafer | Dhinaca dhidibka: ± 0.0001° | Dhinaca dhidibka: ± 0.05° |

| Cufnaanta Dheef-yar | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Iska caabin (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Hanuuninta Flat Primary | (0-10)° ± 5.0° | (10-10)° ± 5.0° |

| Dhererka Guriga aasaasiga ah | Darajo | Darajo |

| Ka saarida cidhifka (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Bowl / Warp | ≤ 3µm | ≤ 3µm |

| Qalafsanaan | Polish Ra ≤ 1.5 µm | Polish Ra ≤ 1.5 µm |

| Chips-ka Cidhifyada Iftiinka Xoogga Sare | ≤20 µm | ≤ 60µm |

| Kuleylka Taarikada Iftiinka Xoogga Sare | Isugeynta ≤ 0.05% | Isugeynta ≤ 3% |

| Meelo Badan Oo Iftiin Xoogan Sare leh | Kaarboonka Muuqaalka ah ≤ 0.05% | Isugeynta ≤ 3% |

| Dusha sare ee Silikoon xoqida Iftiinka xoogga sare | ≤ 0.05% | Isugeynta ≤ 4% |

| Chips-ka Cidhifyada Iftiinka Xoogga Sare (Xajmiga) | Lama Ogolaan> 02mm Balac iyo Qoto dheer | Lama Ogolaan> 02mm Balac iyo Qoto dheer |

| Caawinta Screw Dilation | ≤ 500 µm | ≤ 500 µm |

| Wasakhaynta Dusha Silikoon ee Iftiinka Xoogan Sare | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Baakadaha | Cassette-wafer-badan ama weel wafer oo kali ah | Cassette-wafer-badan ama weel wafer oo kali ah |

4-Inch 4H-Semi Insulating SiC Substrate Caymiska

| Halbeegga | Wax-soo-saarka MPD eber (Grade Z) | Fasalka Dhamaystiran (D Derajada) |

|---|---|---|

| Guryaha Jirka | ||

| Dhexroorka | 99.5 mm - 100.0 mm | 99.5 mm - 100.0 mm |

| Nooca-poly-ga | 4H | 4H |

| Dhumucda | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Hanuuninta Wafer | Dhinaca dhidibka: <600h> 0.5° | Dhanka dhidibka: <000h> 0.5° |

| Guryaha Korontada | ||

| Cufnaanta Micropipe (MPD) | ≤1cm⁻² | ≤15cm⁻² |

| iska caabin | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Dulqaadyada joomatari | ||

| Hanuuninta Flat Primary | (0×10) ± 5.0° | (0×10) ± 5.0° |

| Dhererka Guriga aasaasiga ah | 52.5 mm ± 2.0 mm | 52.5 mm ± 2.0 mm |

| Dhererka Guriga Sare | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| Hanuuninta Guriga Sare | 90° CW oo ka yimid dabaqa Primer ± 5.0° (Si weji kor) | 90° CW oo ka yimid dabaqa Primer ± 5.0° (Si weji kor) |

| Ka saarida gees | 3 mm | 3 mm |

| LTV / TTV / Qaansada / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| Tayada dusha sare | ||

| Roughness dusha sare (Polish Ra) | ≤1 nm | ≤1 nm |

| Dusha sare (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Dildilaaca cidhifka (Iftiinka xoogga badan) | Lama ogola | Dhererka isugeynta ≥10 mm, hal dildilaac ≤2 mm |

| Cilladaha saxan saddex geesoodka ah | ≤0.05% aagga isugeynta | ≤0.1% aagga isugeynta |

| Noocyada ka mid noqoshada aagagga | Lama ogola | ≤1% aagga isugeynta |

| Kaarboon Muuqaal ah | ≤0.05% aagga isugeynta | ≤1% aagga isugeynta |

| Xoqashada dusha sare ee Silicon | Lama ogola | ≤1 dhexroorka wafer dhererka wadarta |

| Chips Edge | Midna lama oggola (≥0.2 mm ballac/ qoto dheer) | ≤5 chips (mid walba ≤1 mm) |

| Wasakhaynta Dusha Silicon | Lama cayimin | Lama cayimin |

| Baakadaha | ||

| Baakadaha | Cajalad badan oo wafer ah ama weel kaliya oo canjeero ah | Cajalad wafer badan ama |

| 6-inch N-nooca Epit axial specification | |||

| Halbeegga | unug | Z-MOS | |

| Nooca | Dabeecadda/Dopant | - | N-nooca / Nitrojiinka |

| Lakabka Buffer | Dhumucda Lakabka Buffer | um | 1 |

| Dulqaadashada Dhumucda lakabka Buffer | % | ± 20% | |

| Isku-xidhka Lakabka Buffer | cm-3 | 1.00E+18 | |

| Dulqaadashada Lakabka Buffer | % | ± 20% | |

| Lakabka Epi 1aad | Dhumucda lakabka Epi | um | 11.5 |

| Midaynta Dhumucda lakabka Epi | % | ± 4% | |

| Dulqaadashada Dhumucda lakabyada Epi ((Spec- Ugu badnaan, Min)/Spec) | % | ± 5% | |

| Isku-duubnida lakabka Epi | cm-3 | 1E 15~ 1E 18 | |

| Dulqaadashada Lakabka Epi | % | 6% | |

| Isku-duubnaanta Isku-duubnida lakabka Epi (σ /macnaha) | % | ≤5% | |

| Lakabka Epi Isku-duubnida <(max-min)/(max+min> | % | ≤ 10% | |

| Qaabka Waferka ee Epitaixal | Qaansada | um | ≤±20 |

| WARP | um | ≤30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤2 | |

| Tilmaamaha Guud | dhererka xaaqid | mm | ≤30mm |

| Chips Edge | - | MIDNA | |

| Qeexitaanka cilladaha | ≥97% ( Lagu cabiray 2*2, Cilladaha dilaaga ah waxaa ka mid ah: Cilladaha waxaa ka mid ah Karootada, saddex xagal | ||

| Wasakhowga birta | atamka/cm² | d f f i ≤5E10 atamka/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Xidhmada | Tilmaamaha xirxirida | pcs/sanduuqa | cajalad wafer ah oo badan ama weel maraf ah oo keliya |

| 8-inch nooca N-qeexitaanka epitaxial | |||

| Halbeegga | unug | Z-MOS | |

| Nooca | Dabeecadda/Dopant | - | N-nooca / Nitrojiinka |

| Lakabka kaydinta | Dhumucda Lakabka Buffer | um | 1 |

| Dulqaadashada Dhumucda lakabka Buffer | % | ± 20% | |

| Isku-xidhka Lakabka Buffer | cm-3 | 1.00E+18 | |

| Dulqaadashada Lakabka Buffer | % | ± 20% | |

| Lakabka Epi 1aad | Celceliska dhumucda lakabyada Epi | um | 8 ~ 12 |

| Midaynta Dhumucda lakabyada Epi (σ/ celcelis ahaan) | % | ≤2.0 | |

| Dulqaadashada Dhumucda lakabyada Epi ((Spec -Max, Min)/Spec) | % | ±6 | |

| Lakabyada Epi Celceliska Doping | cm-3 | 8E+15 ~2E+16 | |

| Epi Layers Net Doping Uniformity (σ/macnaha) | % | ≤5 | |

| Epi Layers Net DopingTolerance ((Spec-Max,) | % | ± 10.0 | |

| Qaabka Waferka ee Epitaixal | Mi )/S) Warp | um | ≤50.0 |

| Qaansada | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm×10mm) | |

| Guud ahaan Astaamaha | xoqid | - | Dhererka isugeynta≤ 1/2 dhexroorka wafer |

| Chips Edge | - | ≤2 chips, Radius kasta≤1.5mm | |

| Wasaqda Biraha Dusha sare | atamka/cm2 | ≤5E10 atamka/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Baadhitaanka cilladaysan | % | ≥ 96.0 (2X2 cilladaha waxaa ka mid ah Micropipe / godad waaweyn, Karootada, cilladaha saddex xagal, hoos u dhaca, Linear/IGSF-s, BPD) | |

| Wasaqda Biraha Dusha sare | atamka/cm2 | ≤5E10 atamka/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Xidhmada | Tilmaamaha xirxirida | - | cajalad wafer ah oo badan ama weel maraf ah oo keliya |

Q1: Waa maxay faa'iidooyinka ugu muhiimsan ee isticmaalka waferrada SiC ee ku saabsan waferrada silikoon ee dhaqameed ee korontada ku shaqeeya?

A1:

Waferrada SiC waxay bixiyaan faa'iidooyin dhowr ah oo muhiim ah marka loo eego silikoon (Si) wafers-dhaqameedka korontada ku shaqeeya, oo ay ku jiraan:

Waxtarka sareSiC waxay leedahay faashad ballaadhan (3.26 eV) marka la barbar dhigo silikoon (1.1 eV), taas oo u oggolaanaysa aaladaha inay ku shaqeeyaan koronto sare, wareegyo, iyo heerkul. Tani waxay keenaysaa hoos u dhaca awoodda iyo waxtarka sare ee nidaamyada beddelka awoodda.

Dhaqdhaqaaqa Kuleylka Sare: Xakamaynta kulaylka ee SiC ayaa aad uga sarreeya kan silikoon, taas oo awood u siinaysa kulaylka wanaagsan ee codsiyada awoodda sare leh, taas oo hagaajinaysa kalsoonida iyo cimriga qalabka korontada.

Korantada Sare iyo Qabashada Hadda: Aaladaha SiC waxay xamili karaan danab sare iyo heerar hadda jira, taasoo ka dhigaysa inay ku habboon yihiin codsiyada awoodda sare leh sida baabuurta korantada, nidaamyada tamarta la cusboonaysiin karo, iyo wadista baabuurta warshadaha.

Xawaaraha beddelka degdega ah: Aaladaha SiC waxay leeyihiin awood beddelasho degdeg ah, taas oo gacan ka geysata dhimista lumitaanka tamarta iyo cabbirka nidaamka, iyaga oo ka dhigaya kuwo ku habboon codsiyada soo noqnoqda.

Q2: Waa maxay codsiyada ugu muhiimsan ee waferrada SiC ee warshadaha baabuurta?

A2:

Warshadaha baabuurta, waferrada SiC ayaa ugu horrayn lagu isticmaalaa:

Gaadiidka Korontada (EV) Tareennada KorontadaQaybaha SiC-ku-salaysan sidarogayaashaiyoMOSFET-yada awooddawanaaji hufnaanta iyo waxqabadka tareennada baabuurta korontada ku shaqeeya adiga oo awood u siinaya xawaaraha beddelka degdega ah iyo cufnaanta tamarta sare. Tani waxay keenaysaa nolosha batteriga oo dheer iyo waxqabadka guud ee baabuurka oo wanaagsan.

Dabaysha-Boardka: Aaladaha SiC waxay gacan ka geystaan hagaajinta hufnaanta nidaamyada ku dallaca guddiga iyaga oo awood u siinaya waqtiyada dallacaadda degdegga ah iyo maaraynta kulaylka wanaagsan, taas oo muhiim u ah EVs si ay u taageeraan saldhigyada awoodda sare leh.

Nidaamyada Maareynta Batteriga (BMS): Tiknoolajiyada SiC waxay hagaajinaysaa waxtarkanidaamyada maareynta batteriga, taasoo u oggolaanaysa nidaaminta korantada ka wanaagsan, maaraynta awoodda sare, iyo nolosha batteriga oo dheer.

Beddelayaasha DC-DC: Waferrada SiC waxaa loo isticmaalaa gudahabeddelayaasha DC-DCsi loogu beddelo tamarta-sare ee DC awoodda korantada yar ee DC si wax ku ool ah, taas oo muhiim u ah baabuurta korontada si ay u maareeyaan awoodda batteriga ilaa qaybaha kala duwan ee gaariga.

Waxqabadka sare ee SiC ee korantada sare, heerkulka sare, iyo hufnaanta sare waxay ka dhigaysaa lama huraan u gudubka warshadaha baabuurta ee dhaqdhaqaaqa korantada.