Saxeexa dhoobada SiC ee Wafer Carrier oo leh iska caabin heerkul sare ah

Saxeexa dhoobada ee Silicon Carbide (SiC Tray)

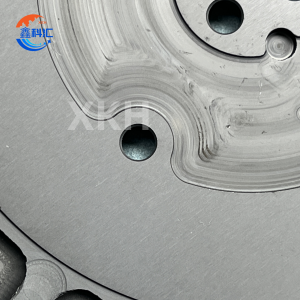

Qayb dhoobo ah oo waxqabadkeedu sarreeyo oo ku salaysan silikoon carbide (SiC), oo loogu talagalay codsiyada warshadaha horumarsan sida wax soo saarka semiconductor iyo wax soo saarka LED. Shaqadeeda xudunta u ah waxaa ka mid ah u adeegida sida wafer-qaade, habka etching, ama taageerada habka heerkulka sare, ka faa'ideysiga kulaylka aan caadiga ahayn, caabbinta heerkulka sare, iyo xasiloonida kiimikada si loo hubiyo isku mid ahaanshaha habka iyo wax soo saarka.

Tilmaamaha Muhiimka ah

1. Waxqabadka kulaylka

- Dhaqdhaqaaqa Heerarka Sare: 140-300 W/m·K, oo si aad ah uga sarreeya garaafka dhaqameed (85 W/m·K), taas oo awood u siinaysa kala-baxa kulaylka degdega ah iyo hoos u dhigista cadaadiska kulaylka.

- Iskuxidhka Balaadhinta Kulaylka Hoose: 4.0 × 10⁻⁶/℃ (25-1000 ℃), silikoon si dhow u dhigma (2.6×10⁻⁶/℃), yaraynta khataraha qallafsanaanta kulaylka.

2. Mechanical Properties

- Xoog Sare: Xoog dabacsan ≥320 MPa (20℃), adkaysi u cadaadis iyo saamaynta.

- Adag-sare: Mohs adag 9.5, labaad oo kaliya dheeman, oo bixiya iska caabin heer sare ah.

3. Xasilloonida Kiimikada

- Iska caabinta daxalka: U adkaysta asiidhyada xooggan (tusaale, HF, H₂SO₄), oo ku habboon jawiga habka xoqidda.

- Non-Magnetic

4. Dulqaadka Deegaanka oo aad u daran

- Joogteynta Heerkulka Sare: Heerkulka hawlgalka muddada-dheer ilaa 1600-1900 ℃; iska caabin muddo gaaban ah ilaa 2200 ℃

- Iska caabinta shoogga kulaylka: Waxay u adkaysataa isbeddelada heerkulka degdega ah (ΔT> 1000 ℃) iyada oo aan dillaacin.

Codsiyada

| Goobta Codsiga | Xaalado gaar ah | Qiimaha Farsamada |

| Wax-soo-saarka Semiconductor | Wafer etching (ICP), dhigista filim khafiif ah (MOCVD), dhalaalid CMP | Wanaajinta kulaylka sare waxay hubisaa goobaha heerkulka isku midka ah; balaadhinta kulaylka hoose waxay yaraynaysaa warwarka wafer. |

| Wax soo saarka LED | Koritaanka Epitaxial (tusaale, GaN), wafer dicing, baakadaha | Waxay xakameysaa cilladaha noocyada badan, kor u qaadaya waxtarka iftiinka LED-ka iyo cimriga. |

| Warshadaha Photovoltaic | Foornooyinka wafer wafer-ka ah, qalabka PECVD ayaa taageera | Heerkulka sare iyo iska caabbinta shoogga kulaylka ayaa kordhiya cimriga qalabka. |

| Laser & Optics | Substrates qaboojinta laysarka awoodda sare leh, nidaamka indhaha ayaa taageera | Dhaqdhaqaaqa kulaylka sare wuxuu awood u siinayaa kuleylka degdega ah, xasilinta qaybaha indhaha. |

| Qalabka Analytical | Sambalayaasha TGA/DSC | Awoodda kulaylka hooseeya iyo ka jawaab celinta kulaylka degdega ah waxay hagaajiyaan saxnaanta cabbirka. |

Faa'iidooyinka Waxsoosaarka

- Waxqabad Dhamaystiran: Dhaqdhaqaaqa kulaylka, xoogga, iyo iska caabbinta daxalka ayaa aad uga badan ceramics alumina iyo silikoon nitride, oo buuxinaya baahiyo hawleed oo xad dhaaf ah.

- Naqshadaynta Fudud: Cufnaanta 3.1-3.2 g/cm³ (40% ee birta), yaraynta culayska aan shaqaynayn iyo kor u qaadida saxnaanta dhaqdhaqaaqa.

- Cimri dheer & Kalsooni: Nolosha adeeggu waxay dhaaftaa 5 sano 1600 ℃, yaraynta wakhtiga hoos u dhaca iyo hoos u dhigida kharashaadka hawlgalka 30%.

- Habaynta

Tilmaamaha Farsamada

| Qaybta Parameter | tilmaame |

| Qalabka Jirka | |

| Cufnaanta | ≥3.10 g/cm³ |

| Xoog Jilicsan (20 ℃) | 320-410 MPa |

| Heerarka kulka (20 ℃) | 140–300 W/(m·K) |

| Isku xidhka Balaadhinta kulaylka (25-1000 ℃) | 4.0×10⁻⁶/℃ |

| Guryaha Kiimikada | |

| Iska caabinta aysiidhka (HF/H₂SO₄) | Wax daxal ah ma jiro 24saac ka dib |

| Saxnaanta Machining | |

| Fiican | ≤15 μm (300×300 mm) |

| Dusha sare (Ra) | ≤0.4 μm |

Adeegyada XKH

XKH waxay bixisaa xalal warshadeed oo dhamaystiran oo ku saabsan horumarinta caadada, farsamaynta saxda ah, iyo xakamaynta tayada adag. Horumarinta gaarka ah, waxay bixisaa nadiifnimo sare (> 99.999%) iyo daloolo (30-50% porosity) xalalka walxaha, oo lagu daray qaabaynta 3D iyo jilitaanka si kor loogu qaado joomatariyada adag ee codsiyada sida semiconductors iyo aerospace. Mashiinka saxda ah wuxuu raacayaa nidaam la hagaajiyay: ka baaraandegidda budada → cadaadis-sostatic / qalalan → 2200 ° C sintering → CNC / dheeman shiidi → kormeer, hubinta dhalaalid heerka nanometer iyo ± 0.01 mm dulqaad cabbir. Xakamaynta tayada waxaa ka mid ah tijaabinta nidaamka buuxa (HRD Halabuurka, SEM microstructure, 3-dhibcood foorarsiga) iyo taageero farsamo (habaynta habka, la-tashiga 24/7, bixinta muunad 48-saac ah), bixinta qaybo lagu kalsoonaan karo, waxqabadka sare ee baahida warshadaha horumarsan.

Su'aalaha Inta Badan La Isweydiiyo (FAQ)

1. S: Waa maxay warshadaha isticmaala saxarada dhoobada ee silicon carbide?

A: Si ballaaran loogu isticmaalo wax soo saarka semiconductor (maareynta wafer), tamarta qoraxda

2. S: Sidee buu silikoon kaarbiide uga sarreeyaa saxaammada quartz/ galaas?

J: Iska caabin shoog heer sare ah oo heerkul sare ah (ilaa 1800°C vs. quartz's 1100°C), faragelinta magnetic eber, iyo cimri dhererka (5+ sano vs.

3. S: saxaarad kaarbide silikoon ma xamili karaan bay'ada aashitada?

J: Haa. U adkaysta HF, H2SO4, iyo NaOH oo leh <0.01mm daxal/sanad, taasoo ka dhigaysa mid ku habboon nadiifinta kiimikada

4. S: Saxanadaha silikoon carbide ma ku habboon yihiin otomaatiga?

J: Haa. Naqshadeynta vacuum ka qaadista iyo maaraynta robotiga, oo leh fidsan oogada <0.01mm si looga hortago wasakheynta walxaha ku jira dharka iswada.

5. S: Waa maxay isbarbardhigga qiimaha iyo agabka dhaqameed?

J: Kharashka hore ee sare (3-5x quartz) laakiin 30-50% hoose TCO