Semiconductor Laser Lift-Off Qalabka Wax Ka Beddelka Khafiifinta Ingot

Jaantus faahfaahsan

Soo Bandhigista Alaabta Qalabka Dabka-Daminta Semiconductor Laser

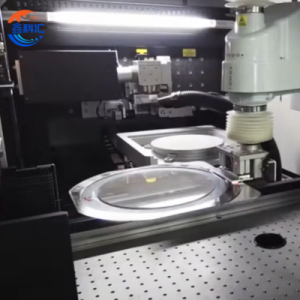

Semiconductor Laser Lift-Off Equipment waa xal warshadeed aad u khaas ah oo loogu talagalay khafiifinta saxda ah iyo kuwa aan la xiriirin ee khafiifinta semiconductor iyada oo loo marayo farsamooyinka kor u qaadista laysarka. Nidaamkan horumarsan waxa uu door muhiim ah ka ciyaara hababka wafering semiconductor-ka casriga ah, gaar ahaan samaynta waferrada aadka u dhuuban ee korantada wax-qabadka sare leh ee korantada, LED-yada, iyo aaladaha RF. Iyada oo awood u siinaysa kala-soocidda lakabyada khafiifka ah ee ka soocida bulk ama substrates deeq-bixiyayaasha, Semiconductor Laser Lift-Off Equipment waxay wax ka beddeshaa khafiifinta miskaha iyada oo meesha ka saaraysa miinshaarka farsamada, shiidida, iyo tillaabooyinka xoqidda kiimikada.

khafiifinta dhaqameed ee ingots semiconductor, sida gallium nitride (GaN), silicon carbide (SiC), iyo sapphire, inta badan waa xoog badan tahay, qashin, oo u nugul microcracks ama waxyeelo dusha sare ah. Taas bedelkeeda, Qalabka kor-u-qaadista ee Semiconductor Laser wuxuu bixiyaa beddelaad sax ah oo aan burburin, kaas oo yareynaya luminta walxaha iyo walbahaarka dusha sare iyadoo la kordhinayo wax soo saarka. Waxay taageertaa noocyo kala duwan oo ah crystalline iyo walxaha isku dhafan waxaana si aan kala go 'lahayn loogu dari karaa khadadka wax soo saarka semiconductor-dhamaadka hore ama dhexe.

Mawjadaha dhererka leysarka ee la habeyn karo, nidaamyada diiradda la qabsiga, iyo jeexjeexyada vacuum-ku habboon, qalabkani wuxuu si gaar ah ugu habboon yahay goynta goynta, abuurista lamella, iyo goosashada filimka aadka u khafiifka ah ee qaab-dhismeedka qalabka toosan ama wareejinta lakabka heteroepitaxial.

Halbeegga Qalabka Dab-ka-qaadista ee Semiconductor Laser

| Mawjada dhererka | IR/SHG/THG/FHG |

|---|---|

| Ballaca garaaca | Nanosecond, Picosecond, Femtosecond |

| Nidaamka indhaha | Nidaamka indhaha ee go'an ama Galvano-optical system |

| Marxaladda XY | 500 mm × 500 mm |

| Range Processing | 160 mm |

| Xawaaraha dhaqdhaqaaqa | Ugu badnaan 1,000 mm/sek |

| Ku celcelinta | ± 1 μm ama ka yar |

| Saxnaanta Mawqifka Dhabta ah: | ± 5 μm ama ka yar |

| Cabirka Wafer | 2-6 inji ama la habeeyey |

| Xakamaynta | Windows 10,11 iyo PLC |

| Korontada Supply | AC 200 V ± 20 V, Hal-waji, 50/60 kHz |

| Cabbirrada Dibadda | 2400 mm (W) × 1700 mm (D) × 2000 mm (H) |

| Miisaanka | 1,000 kg |

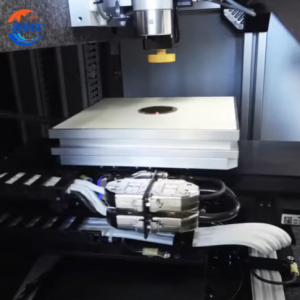

Mabaadi'da Shaqada ee Qalabka Kor-u-qaadista Laysarka Semiconductor

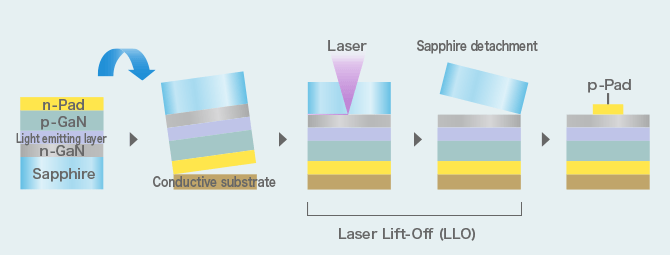

Habka xudunta u ah Qalabka Lift-Off ee Semiconductor Laser-ku wuxuu ku tiirsan yahay kala-soocidda photothermal ee xulashada ama baabi'inta isdhexgalka u dhexeeya deeq-bixiyaha iyo lakabka epitaxial ama bartilmaameedka. Laysarka tamarta sare ee UV (sida caadiga ah KrF oo ah 248 nm ama leysarka UV ee adag ee ku wareegsan 355 nm) ayaa diirada lagu saaray iyada oo loo marayo walxo deeq bixiye ah oo hufan ama dhexdhexaad ah, halkaas oo tamarta si xushmad leh loogu nuugo qoto dheer oo hore loo go'aamiyay.

Nuugista tamarta deegaanku waxay abuurtaa weji gaas cadaadis-sare leh ama lakabka fidinta kulaylka ee interface-ka, kaas oo bilaaba delamination nadiif ah ee waferka sare ama lakabka qalabka laga bilaabo saldhigga la geliyey. Nidaamku si fiican ayaa loo hagaajiyay iyadoo la hagaajinayo cabbirrada sida ballaca garaaca wadnaha, faleelka laysarka, xawaaraha sawirida, iyo qoto-dheeraanta dhidibka z-axis. Natiijadu waa jeex dhuuban-badanaa inta u dhaxaysa 10 ilaa 50 µm — si nadiif ah uga soocday waalidkii oo aan xoqin makaanikada.

Habkan qaadista laysarka ee khafiifinta qallafsan waxay ka fogaanaysaa luminta kerf iyo dhaawaca dusha sare ee la xidhiidha miinshaarka siliga dheemanka ama jilitaanka farsamada. Waxa kale oo ay ilaalisaa daacadnimada kristanta waxayna yaraynaysaa shuruudaha dhalaalka hoose, samaynta Semiconductor Laser Lift-Off Qalabka qalab beddelka ciyaarta wax soo saarka wafer-ka soo socda.

Codsiyada Qalabka Kor-u-qaadista Laysarka Semiconductor

Semiconductor Laser Lift-Off Equipment waxay helaysaa ku-dhaqanka ballaadhan ee khafiifinta qallafsan ee agabka iyo noocyada aaladaha kala duwan, oo ay ku jiraan:

-

GaN iyo GaAs Ingot Thinning ee Qalabka Korontada

Waxay u sahlaysa abuurista maraqa khafiifka ah ee waxtarka sare leh, awood-iska-caabbinta hoose iyo diodka.

-

Soo-celinta Substrate-ka SiC iyo Kala-soocidda Lamella

Oggolow ka-qaadista cabbirka wafer-ka ee bustaha SiC-ga ee qaab-dhismeedka aaladaha toosan iyo dib-u-isticmaalka waferka.

-

Goynta Waferka LED

Waxay sahlaysa ka-qaadista lakabyada GaN-ka ee sapphire ingots qaro weyn si ay u soo saaraan substrate-ka LED-ka ee aadka u dhuuban.

-

RF iyo Aaladda Microwave ee Farsamaynta

Waxay taageertaa qaab-dhismeedyada aadka u khafiifsan ee-electron-mobility transistor (HEMT) ee looga baahan yahay nidaamyada 5G iyo radar.

-

Wareejinta lakabka Epitaxial

Wuxuu si sax ah uga soocaa lakabyada epitaxial ee xinjirowga crystalline si dib loogu isticmaalo ama loogu daro qaab-dhismeedka heterostructures.

-

Unugyada Cadceedda-Filimka khafiifka ah iyo Sawir-qaadayaasha

Loo isticmaalo in lagu kala saaro lakabyada nuugista dhuuban ee unugyada qorraxda dabacsan ama waxtarka sare leh.

Mid kasta oo ka mid ah xayndaabkan, Semiconductor Laser Lift-Off Equipment wuxuu bixiyaa kontorool aan la qiyaasi karin oo ku saabsan lebbiska dhumucda, tayada dusha sare, iyo daacadnimada lakabka.

Faa'iidooyinka Leas-ku-saleysan Ingot khafiifinta

-

Waayida Walxaha eber-Kerf

Marka la barbar dhigo hababka wax lagu jarjaro wafer-dhaqameedka, habka laysarka wuxuu keenaa ku dhawaad 100% isticmaalka walxaha.

-

Cadaadiska Ugu Yar iyo Warping

Kor u qaadista aan xiriirka lahayn waxay baabi'isaa gariirka farsamada, yaraynta qaansada wafer iyo samaynta microcrack.

-

Ilaalinta Tayada Dusha sare

Looma baahna dharbaaxo khafiif ah ka dib ama dhalaalid loo baahan yahay xaalado badan, maaddaama qaadista laser-ka ay ilaaliso daacadnimada dusha sare.

-

Wax-soo-saarka Sare iyo Diyaarinta Automation-ka

Awood u leh in uu ku habeeyo boqollaal substrate-ka shifti kasta oo la rarid/ dejin toos ah.

-

Laqabsankaro Qalabyo Badan

La jaan qaadaya GaN, SiC, sapphire, GaAs, iyo agabka soo baxaya ee III-V.

-

Badbaado deegaan ahaan

Waxay yaraynaysaa isticmaalka abrasives iyo kiimikooyinka adag ee caadiga ah ee hababka khafiifinta ku salaysan slurry.

-

Dib u Isticmaalka Substrate

Ku-deeqaha deeq-bixiyeyaasha waxa dib loo warshadayn karaa wareegyo badan oo wax-ka-qaadis ah, taas oo aad u yaraynaysa kharashaadka alaabta.

Su'aalaha Inta badan La Isweydiiyo (FAQ) ee Qalabka Dab-ka-qaadista Semiconductor Laser

-

Q1: Waa maxay dhumucda kala duwan ee Semiconductor Laser Lift-Off Equipment ku gaari karaa xaleef wafer?

A1:Dhumucdiisuna waxay u dhaxaysaa 10 µm ilaa 100 µm iyadoo ku xidhan shayga iyo qaabaynta.Q2: Qalabkan ma loo isticmaali karaa in lagu khafiifiyo jeexjeexyada ka samaysan walxaha aan muuqan sida SiC?

A2:Haa Iyada oo la hagaajinayo hirarka dhererka laysarka iyo hagaajinta injineernimada is-dhexgalka (tusaale, is-dhex-galayaasha allabaryo), xitaa qayb ahaan agabka mugdiga ah waa la farsamayn karaa.Q3: Sidee buu substrate-ka deeq-bixiyuhu u siman yahay ka hor inta aan layska saarin?

A3:Nidaamku waxa uu isticmaalaa unugyo isku toosan oo ku salaysan aragga-micro-hoosaadka oo leh jawaab celin ka timid calamadaha daacadda ah iyo sawirada milicsiga oogada.Q4: Waa maxay wakhtiga wareegga la filayo ee hal hawlgal wiish laser ah?

A4:Iyadoo ku xiran xajmiga waferka iyo dhumucda, wareegyada caadiga ah waxay soconayaan 2 ilaa 10 daqiiqo.Q5: Nidaamku ma u baahan yahay deegaan qol nadiif ah?

A5:Inkastoo aysan qasab ahayn, isku dhafka qolka nadiifka ah ayaa lagula talinayaa in la ilaaliyo nadaafadda substrate-ka iyo wax-soo-saarka aaladaha inta lagu jiro hawlgallada saxda ah.

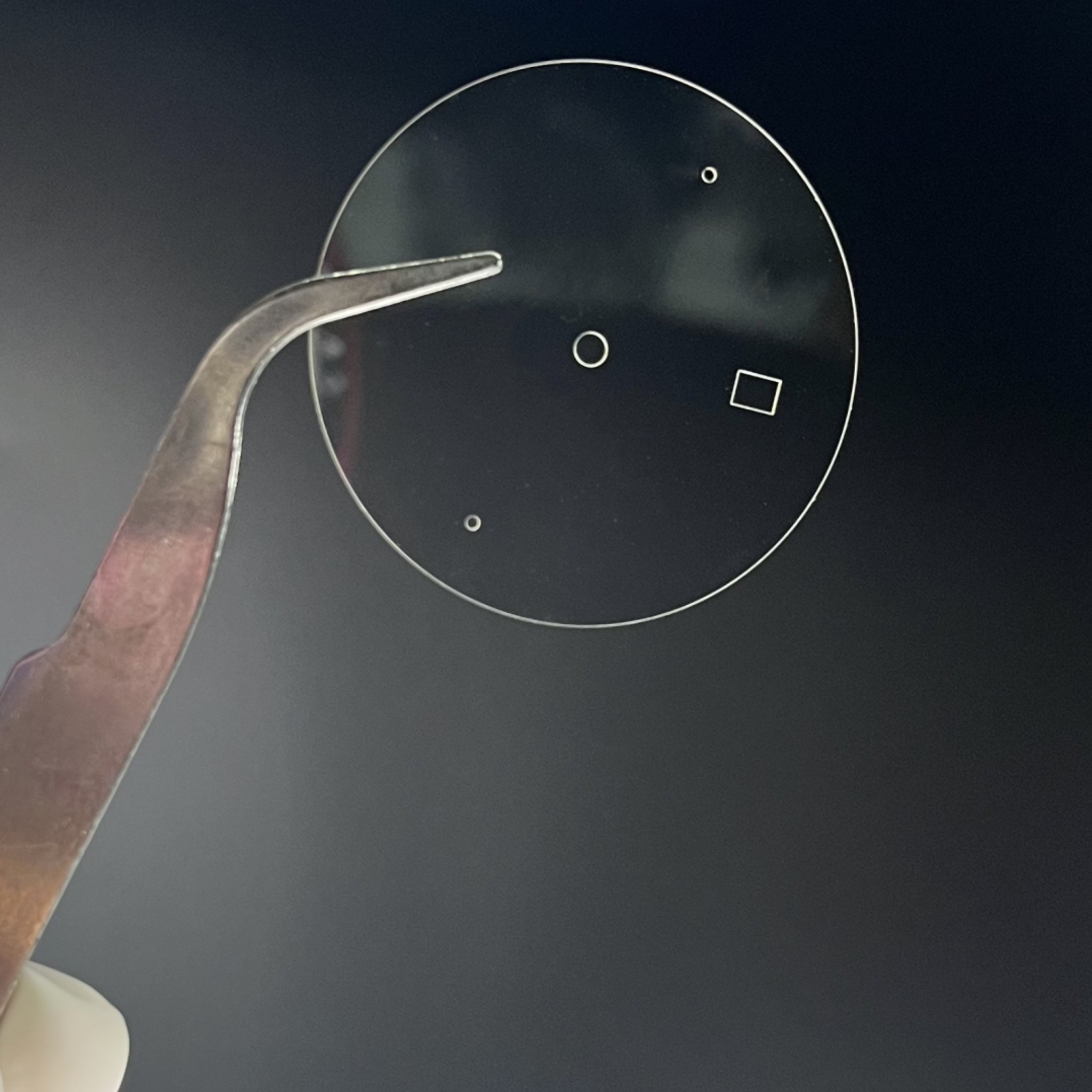

Annaga

XKH waxay ku takhasustay horumarinta tignoolajiyada sare, wax soo saarka, iyo iibinta muraayadaha indhaha ee gaarka ah iyo agabka cusub ee crystal. Badeecadahayadu waxay u adeegaan qalabka elektarooniga ah, elektiroonigga macaamiisha, iyo militariga. Waxaan bixinaa qaybaha indhaha ee Sapphire, daboolka muraayadda taleefanka gacanta, Ceramics, LT, Silicon Carbide SIC, Quartz, iyo maraqyada crystal semiconductor. Iyada oo leh khibrad xirfad leh iyo qalab-goynta, waxaan ku fiicanahay habaynta badeecada aan caadiga ahayn, annagoo higsanayna inaan noqono hormuudka agabka optoelectronic shirkad farsamo sare leh.