Semiconductor Laser Qalabka Kor-u-qaadka

Jaantus faahfaahsan

Dulmarka alaabta ee Qalabka Kor-u-qaadista Laser

Semiconductor Laser Lift-Off Equipment waxay u taagan tahay xalka jiilka soo socda ee khafiifinta horumarsan ee wax-soo-saarka semiconductor. Si ka duwan hababka wafering dhaqameed ee ku tiirsan shiidi mishiinka, miinshaar silig dheeman, ama qorshaynta kiimikaad-farsamo, madal-ku-salaysan laser-ku-salaysan waxay bixisaa xiriir-free, beddelka aan burburin oo ka go'aya lakabyada aadka u khafiifka ah ee semiconductor badan.

Waxaa loo habeeyay qalabka jajaban iyo kuwa qiimaha sare leh sida gallium nitride (GaN), silicon carbide (SiC), sapphire, iyo gallium arsenide (GaAs), Semiconductor Laser Lift-Equipment waxay awood u siineysaa in si sax ah loo gooyo filimada cabbirka wafer-ka si toos ah uga soo gala galaaska crystal. Tiknoolajiyadan horumarsan waxay si weyn u yaraynaysaa qashinka walxaha, waxay wanaajisaa wax soo saarka, waxayna kor u qaadaysaa daacadnimada substrate - kuwaas oo dhamaantood muhiim u ah aaladaha soo socda ee korantada elektiroonigga ah, nidaamyada RF, sawir-qaadista, iyo bandhigyada-yar.

Iyada oo xoogga la saarayo kontoroolka otomaatiga ah, qaabeynta iftiinka, iyo falanqaynta isdhexgalka walxaha laser-ka, Qalabka Sare-qaadista ee Semiconductor Laser waxaa loogu talagalay in uu si aan kala go 'lahayn ugu dhex milmo qulqulka warshadaynta semiconductor iyada oo la taageerayo dabacsanaanta R&D iyo miisaan wax soo saar ballaaran.

Farsamada & Mabda'a Hawlgelinta Qalabka Laysarka Dabka Ka Qaado

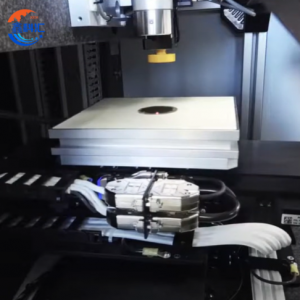

Habka uu sameeyo Semiconductor Laser Lift-Off Equipment wuxuu ku bilaabmaa iyada oo ka iftiiminaysa deeq-bixiyaha hal dhinac iyadoo la adeegsanayo laydhka ultraviolet tamar sare leh. Laydhkani waxa uu si adag diiradda u saaray qoto dheer oo gudaha ah, sida caadiga ah iyada oo la socota is-dhexgalka injineernimada, halkaas oo nuugista tamarta la kordhiyo sababtoo ah isbarbardhigga indhaha, kulaylka, ama kiimikada.

Lakabka nuugista tamarta, kuleylinta deegaanka waxay keentaa qarax yar oo degdeg ah, balaadhinta gaaska, ama burburka lakabka wajiga dhexdooda ah (tusaale, filim walbahaarka ama sacrificial oxide). Khalkhalkan sida saxda ah loo xakameeyay wuxuu sababaa lakabka crystalline-ka sare - oo leh dhumucdiisuna tahay tobanaan micromitir - inay ka go'do saldhigga si nadiif ah.

Semiconductor Laser Lift-Off Equipment waxay kaalmaynaysaa madax sawireedka dhaqdhaqaaqa isku-dhafan, kantaroolka dhidibka z-axis, iyo milicsiga wakhtiga-dhabta ah si loo hubiyo in garaac kastaa uu tamar si sax ah ugu keeno diyaaradda la beegsanayo. Qalabka waxa kale oo lagu habayn karaa qaab-qarxinta ama awoodaha garaaca garaaca badan si kor loogu qaado jilicsanaanta kala goynta oo loo yareeyo walbahaarka hadhaaga ah. Muhiimad ahaan, sababtoo ah iftiinka laysarka waligiis lama xiriirin walxaha jir ahaan, khatarta microcracking, foorarsiga, ama jajabinta dusha sare si aad ah ayaa loo yareeyaa.

Tani waxay ka dhigaysa habka khafiifinta qaadista laysarka mid wax ka beddela ciyaarta, gaar ahaan codsiyada meelaha ultra-flat, ultra- khafiif ah loo baahan yahay TTV-hoosaadka (Isugeynta Dhumucda Kala Duwanaanta).

Halbeegga Qalabka Dab-ka-qaadista ee Semiconductor Laser

| Mawjada dhererka | IR/SHG/THG/FHG |

|---|---|

| Ballaca garaaca | Nanosecond, Picosecond, Femtosecond |

| Nidaamka indhaha | Nidaamka indhaha ee go'an ama Galvano-optical system |

| Marxaladda XY | 500 mm × 500 mm |

| Range Processing | 160 mm |

| Xawaaraha dhaqdhaqaaqa | Ugu badnaan 1,000 mm/sek |

| Ku celcelinta | ± 1 μm ama ka yar |

| Saxnaanta Mawqifka Dhabta ah: | ± 5 μm ama ka yar |

| Cabirka Wafer | 2-6 inji ama la habeeyey |

| Xakamaynta | Windows 10,11 iyo PLC |

| Korontada Supply | AC 200 V ± 20 V, Hal-waji, 50/60 kHz |

| Cabbirrada Dibadda | 2400 mm (W) × 1700 mm (D) × 2000 mm (H) |

| Miisaanka | 1,000 kg |

Codsiyada Wershadaha ee Qalabka Kor-u-qaadista Laser-ka

Semiconductor Laser Lift-Off Qalabka ayaa si degdeg ah u beddelaya sida agabka loogu diyaariyey qaybo badan oo semiconductor ah:

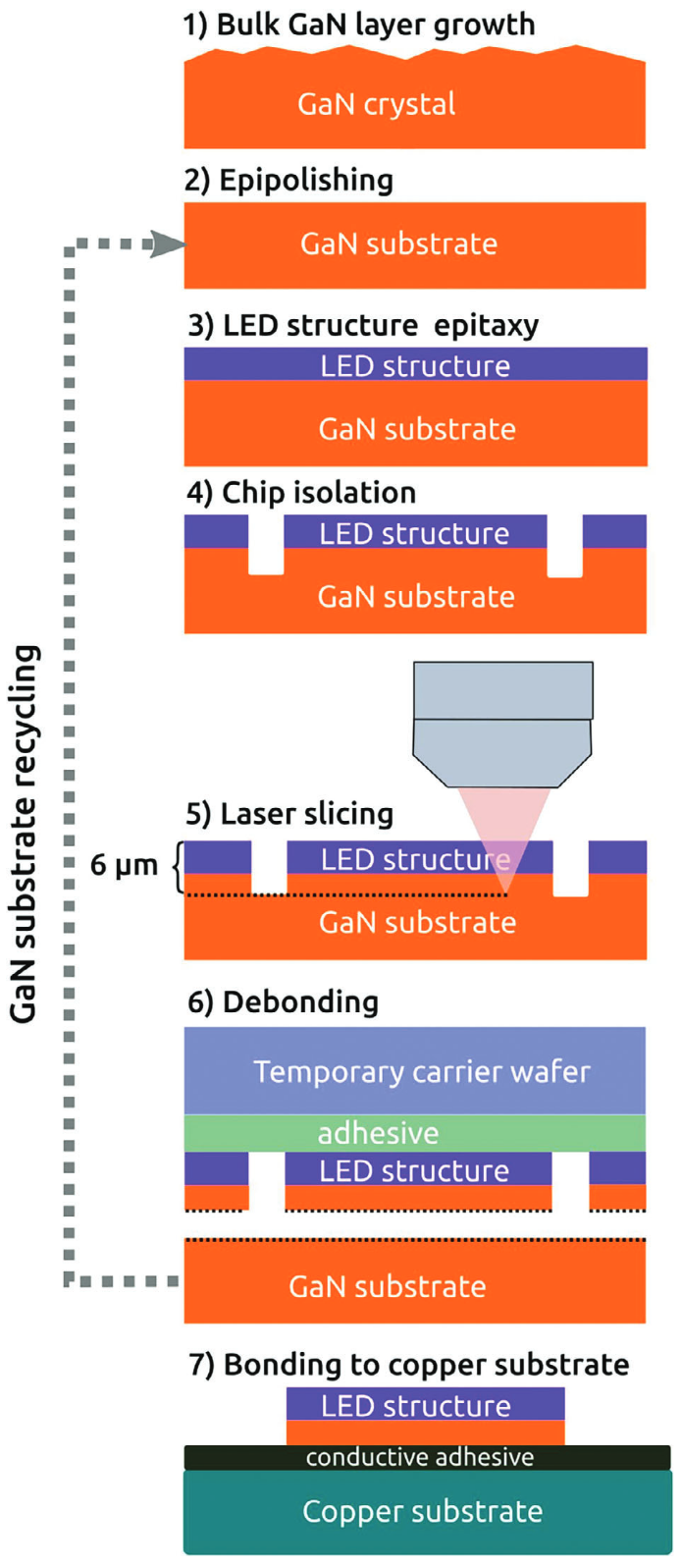

- Aaladaha Korantada GaN ee Tooska ah ee Qalabka Dabka Laysarka ah

Ka-qaadista filimada aadka u khafiifka ah ee GaN-on-GaN ee laga soo qaaday ingots bulk waxay awood u siinaysaa qaab-dhismeedka toosan iyo dib u isticmaalka substrate-ka qaaliga ah.

- Khafiifinta SiC Wafer ee Qalabka Schottky iyo MOSFET

Waxay yaraynaysaa dhumucda lakabka aaladda iyadoo la ilaalinayo planarity substrate - ku habboon korontada degdegga ah ee elektiroonigga ah.

- Ilays-ku-saleysan Sapphire iyo Qalabka Muujinta ee Qalabka Dabka-Leerka ah

Waxay u sahlaysa kala-soocidda wax-ku-oolka ah ee lakabyada aaladaha laga soo bilaabo sapphire boules si ay u taageerto dhuuban, kuleyl ahaan wax soo saarka-LED-yar.

- III-V Injineeriyada Qalabka ee Qalabka Kor-u-qaadista Laser

Waxay fududaysaa kala goynta GaAs, InP, iyo AlGaN lakabyada is dhexgalka sare ee indhaha.

- Khafiif-Wafer IC iyo farsamaynta dareemayaasha

Waxay soo saartaa lakabyo shaqaynaya oo khafiif ah oo loogu talagalay dareemeyaasha cadaadiska, xawaaraha-mitirka, ama sawir-qaadayaasha, halkaas oo budhku uu yahay dhalo waxqabad.

- Elektaroonigga dabacsan oo hufan

Wuxuu diyaariyaa substrate-ka dhuuban ee ku habboon bandhigyada dabacsan, wareegyada xiran, iyo daaqadaha smart ee hufan.

Mid kasta oo ka mid ah aagaggaan, Semiconductor Laser Lift-Off Equipment wuxuu ka ciyaaraa door muhiim ah awood u yeelashada yaraynta, dib u isticmaalka alaabta, iyo fududaynta habka.

Su'aalaha Inta Badan La Isweydiiyo (FAQ) ee Qalabka Laysarka Daminta

Q1: Waa maxay dhumucda ugu yar ee aan ku gaari karo isticmaalka Semiconductor Laser Equipment?

A1:Caadi ahaan inta u dhaxaysa 10-30 microns iyadoo ku xiran walxaha. Nidaamku wuxuu awood u leeyahay natiijooyin khafiif ah oo leh habayn wax laga beddelay.

Q2: Tan ma loo isticmaali karaa in lagu jeexo wafers badan oo isku mid ah?

A2:Haa Macaamiil badan ayaa isticmaala farsamada kor-u-qaadista laysarka si ay u sameeyaan soosaaryo taxane ah oo lakabyo dhuuban oo badan oo laga soo qaaday hal xabbo.

Q3: Maxay yihiin sifooyinka badbaadada ee lagu daray hawlgalka laser-ka sare?

A3:Xeryaha fasalka 1-aad, nidaamyada isku-xidhka, gaashaanka iftiinka, iyo xidhitaanka otomaatiga ah dhammaantood waa heer.

Q4: Sidee ayuu nidaamkani u barbar dhigayaa miinshaarta siliga dheemanka ah marka loo eego kharashka?

A4:Iyadoo capex bilowga ah laga yaabo inuu sarreeyo, qaadista laser-ka waxay si aad ah u yaraynaysaa kharashyada la isticmaali karo, burburka substrate-ka, iyo talaabooyinka habaynta ka dib - hoos u dhigista wadarta qiimaha lahaanshaha (TCO) muddada dheer.

Q5: Hannaanka ma lagu qiyaasi karaa 6-inch ama 8-inch ingots?

A5:Dhab ahaantii. Madalku waxay taageertaa ilaa 12-inch substrates oo leh qaybinta alwaax isku mid ah iyo marxalado dhaqdhaqaaq qaabaysan.

Annaga

XKH waxay ku takhasustay horumarinta tignoolajiyada sare, wax soo saarka, iyo iibinta muraayadaha indhaha ee gaarka ah iyo agabka cusub ee crystal. Badeecadahayadu waxay u adeegaan qalabka elektarooniga ah, elektiroonigga macaamiisha, iyo militariga. Waxaan bixinaa qaybaha indhaha ee Sapphire, daboolka muraayadda taleefanka gacanta, Ceramics, LT, Silicon Carbide SIC, Quartz, iyo maraqyada crystal semiconductor. Iyada oo leh khibrad xirfad leh iyo qalab-goynta, waxaan ku fiicanahay habaynta badeecada aan caadiga ahayn, annagoo higsanayna inaan noqono hormuudka agabka optoelectronic shirkad farsamo sare leh.