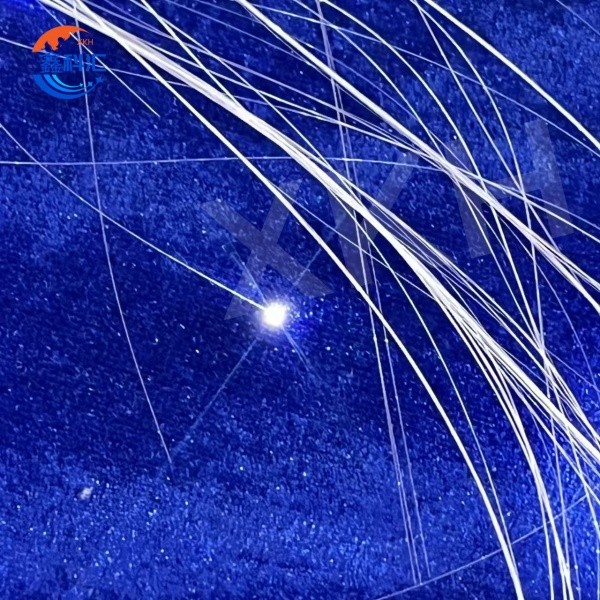

Sapphire fiber single crystal Al₂O₃ barta dhalaalka gudbinta indhaha sare 2072℃ waxaa loo isticmaali karaa qalabka daaqada laysarka

Habka diyaarinta

1. Fiber Sapphire waxaa sida caadiga ah lagu diyaariyaa habka saldhigga kuleylaha laser (LHPG). Habkan, fiber sapphire oo leh dhidibka joomatari iyo dhidibka C ayaa lagu kori karaa, kaas oo gudbin wanaagsan ku leh qaybta infrared agteeda. Khasaaruhu wuxuu inta badan ka yimaadaa kala firdhiso oo ay sababto cilladaha crystal-ka ee ka jira ama dushiisa fiber-ka.

2. Diyaarinta silica clad fiber sapphire: Marka hore, daahan poly (dimethylsiloxane) ayaa lagu dhejiyaa dusha sare ee fiber sapphire oo la daaweeyay, ka dibna lakabka la daaweeyay ayaa loo beddelaa silica at 200 ~ 250 ℃ si loo helo silica clad sapphire fiber. Habkani wuxuu leeyahay heerkulka habka hooseeya, hawlgalka fudud iyo waxtarka sare ee habka.

3.Preparation of sapphire fiber koorta: Qalabka koritaanka habka kuleylinta laysarka waxaa loo isticmaalaa in lagu diyaariyo fiber koorta sapphire iyadoo la xakameynayo xawaaraha qaadista ee sapphire abuur crystal abuur iyo xawaaraha quudinta ee sapphire crystal il ul. Habkani wuxuu diyaarin karaa fiber conical sapphire leh dhumuc kala duwan iyo dhamaadka wanaagsan, kaas oo buuxin kara shuruudaha codsiga gaarka ah.

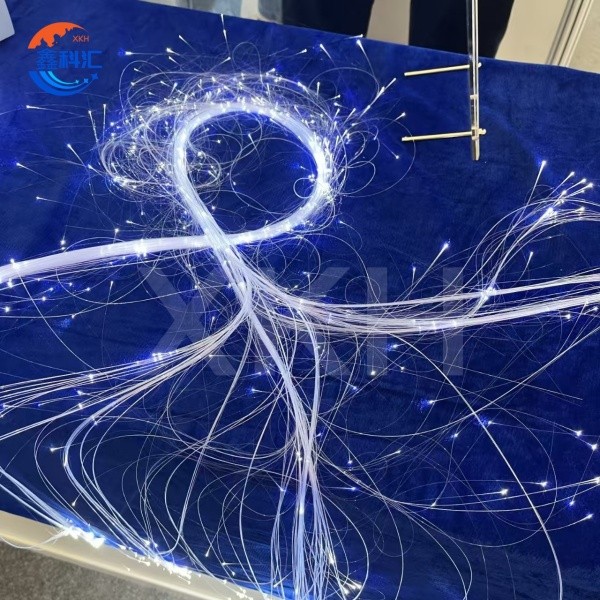

Noocyada fiber-ka iyo sifooyinka

Kala duwanaanshaha 1.Diameter: Dhexroorka fiber sapphire ayaa la dooran karaa inta u dhaxaysa 75 ~ 500μm si loo waafajiyo shuruudaha codsiga kala duwan.

2. Fiber Conical: Fiber sapphire conical wuxuu gaari karaa gudbinta tamarta iftiinka sare iyada oo la hubinayo dabacsanaanta fiber-ka. Fiberkani waxa uu wanaajiyaa hufnaanta gudbinta tamarta iyada oo aan la hurin dabacsanaan.

3. Bushings iyo Xidhiidhiyayaasha: Fiber indhaha leh dhexroor ka weyn 100μm, waxaad dooran kartaa in aad isticmaasho polytetrafluoroethylene (PTFE) bushings ama xidhidhiye fiber indhaha si ay u ilaaliyaan ama isku xidhka.

Goobta codsiga

1.High heerkulka fibre dareemayaasha: Fiber Sapphire sababtoo ah caabbinta heerkulka sare, caabbinta daxalka kiimikada, aad ugu habboon dareenka fiber jawi heerkulka sare. Tusaale ahaan, xagga birta, warshadaha kiimikaad, daaweynta kulaylka iyo meelaha kale, dareemaha heerkulka sare ee sapphire fiber waxay si sax ah u cabbiri karaan heerkulka ilaa 2000 ° C.

2.Laser wareejinta tamarta: Tilmaamaha gudbinta tamarta sare ee fiber sapphire ayaa ka dhigaya mid si weyn loogu isticmaalo goobta wareejinta tamarta laysarka. Waxaa loo isticmaali karaa sidii qalab daaqad ah oo loogu talagalay laysarka si ay ugu adkeystaan shucaaca laysarka ee xoogga badan iyo jawiga heerkulka sare.

Qiyaasta heerkulka warshadaha 3.Industrial: Marka la eego cabbiraadda heerkulka warshadaha, sapphire fiber dareemayaasha heerkulka sare waxay ku siin karaan xogta cabbirka heerkulka saxda ah oo deggan, taas oo ka caawisa la socodka iyo xakamaynta isbeddelka heerkulka ee habka wax soo saarka.

4. Cilmi-baadhis cilmiyeed iyo caafimaad: Dhinaca cilmi-baadhista sayniska iyo daawaynta, faybarka sapphire waxa kale oo loo adeegsadaa cabbiraadyo kala duwan oo sax ah oo indho-indheyn ah iyo codsiyada dareenka sababtoo ah sifooyinka gaarka ah ee jirka iyo kiimikada.

Xuduudaha farsamada

| Halbeegga | Sharaxaada |

| Dhexroorka | 65um |

| Aperture tirooyinka | 0.2 |

| Range dhererka hirarka | 200nm - 2000nm |

| Attenuation/ lumin | 0.5 dB/m |

| Xakamaynta Awoodda ugu badan | 1w |

| Habdhaqanka kulaylka | 35 W/ (m·K) |

Marka loo eego baahiyaha gaarka ah ee macaamiisha, XKH waxay bixisaa adeegyo naqshadaynta caadadii sapphire fiber shakhsi ahaaneed. Haddii ay tahay dhererka iyo dhexroorka fiilada, ama shuruudaha waxqabadka indhaha ee gaarka ah, XKH waxay siin kartaa macaamiisha xalka ugu fiican si ay u daboolaan baahidooda codsi iyada oo loo marayo naqshad xirfadeed iyo xisaabin. XKH waxay leedahay tignoolajiyada wax soo saarka fibre sapphire oo horumarsan, oo ay ku jirto habka saldhiga kuleylka leysarka (LHPG), si loo soo saaro tayo sare leh, fiber sapphire wax qabad sare leh. XKH waxay si adag u xakameysaa xiriir kasta oo ka mid ah habka wax soo saarka si loo hubiyo in tayada badeecada iyo waxqabadka ay la kulmaan rajada macaamiisha.

Jaantus faahfaahsan