Mashiinka Tooshka Robotiga - Dhammaystirka dusha sare ee toosan ee saxda ah

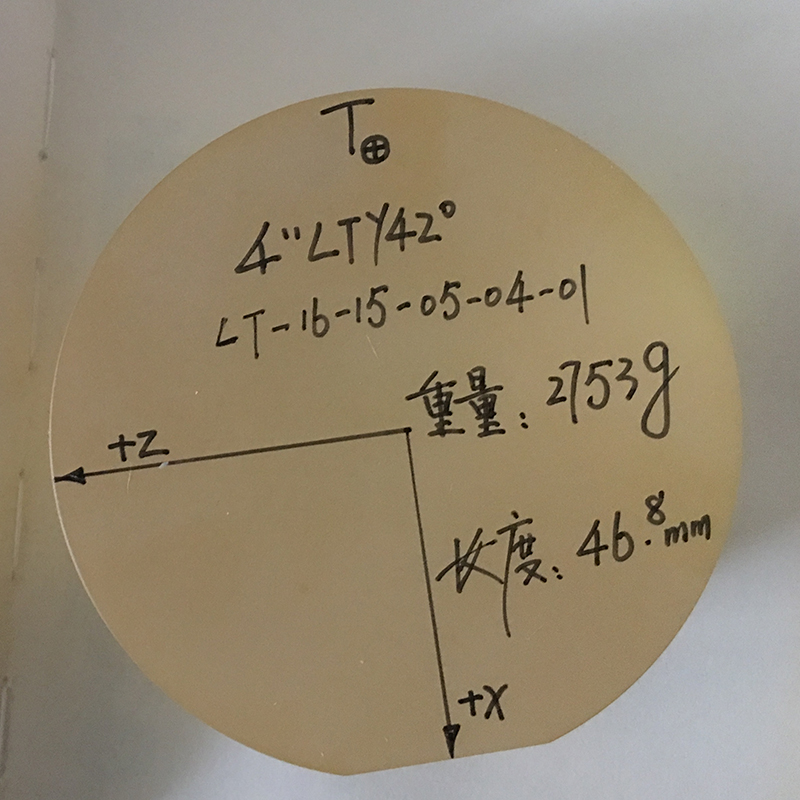

Jaantus faahfaahsan

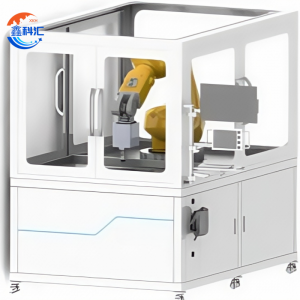

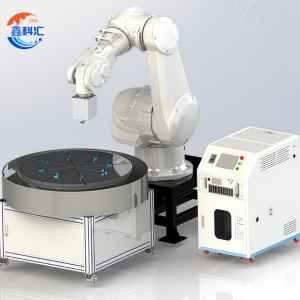

Dulmar guud ee Mashiinka Polishing Robotic

Mashiinka Polishing Machine-ka Robotic waa mid horumarsan, oo si buuxda otomaatig ah ugu habaysan oo loogu talagalay in lagu buuxiyo shuruudaha ugu sarreeya ee wax soo saarka saxda ah. Waxay isku daraysaa lix dhidib ah kantaroolka robotiga ah, tignoolajiyada dib-u-celinta xoog-celinta, iyo qaabeynta laba-madaxa ah si loo maareeyo agabyo kala duwan iyo joomatariyaal adag oo sax ah oo joogto ah.

Haddi ay ahaan lahayd muraayadaha indhaha, qaybaha hawada hawada, qaybaha injineernimada saxda ah, ama codsiyada semiconductor, mishiinkani waxa uu keenaa dhammays dagan, lagu celin karo, iyo tayo sare oo dusha sare ah-xitaa dulqaadka heerka nanometer-ka.

Wanaagsanaanta Qalabka Shaqada ee Dhameystiran ee Mashiinka Daloolinta Robotiga

Nidaamku wuxuu taageeraa habaynta:

-

Oogada fidsandhalooyinka, ceramics, iyo taarikada birta ah

-

Qaababka cylindrical iyo conicalsida rollers, shafts, iyo tubes

-

Qaybaha wareega iyo asphericalhababka indhaha

-

Qaabka xorta ah iyo dusha sare ee dhidibka ka baxsanoo leh qaloocyo adag iyo kala-guurid

Kala duwanaanshaheeda ayaa ka dhigaya mid ku habboonwax-soo-saarka ballaaran iyo wax-soo-saarka caadada ah ee saxda ah labadaba.

Astaamaha Muhiimka ah & Faa'iidooyinka Mashiinka Tooshka Robotiga

1. Tiknoolajiyada madaxa ee laba-laabashada

-

Lagu qalabeeyayhal-wareegiyois-wareejinmadax fiiqid dabacsanaan.

-

Awoodda isbeddelka qalabka degdega ah waxay taageertaa habab farsameedyo badan iyada oo aan wakhti dheer la helin.

-

Ku habboon in loo kala beddelo inta u dhaxaysa marxaladaha dhalaalidda qallafsan iyo kuwa wanaagsan.

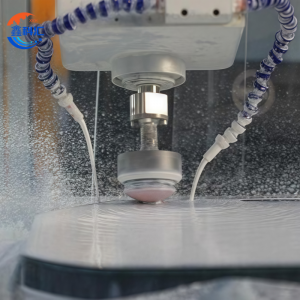

2. Habka Xakamaynta Ciidanka-Suxdinta

-

la socodka waqtiga-dhabta ah eecadaadiska, heerkulka, iyo qulqulka dareeraha dhalaalaysa.

-

Codsiga xoogga joogtada ahi waxa uu hubinayaa in dusha sare ee lebbiska ah uu dhammaanayo qaybta shaqada.

-

Awood u leh in uu si toos ah ula qabsado cilladaha dusha sare.

3. Xakamaynta Robotic-ka ee Lix-Axis

-

Xoriyad buuxda oo dhaq-dhaqaaq si aad u maamusho joomatariyada adag.

-

Waddooyin dhaq-dhaqaaq sax ah oo siman oo sax ah oo lagu xisaabiyo algorithms horumarsan.

-

Xaqiijinta meelaynta sare ee ku celcelinta min ± 0.04 mm ilaa ± 0.1 mm taas oo ku xidhan moodelka.

4. Smart Automation & Cabbir

-

Aaladaha toosinta tooska ah ee habaynta iyo toosinta saxda ah.

-

Isku-dubarid nidaamka cabbirka meelaynta saxda ah.

-

Ikhtiyaarila socodka dhumucda onlinesi loo xakameeyo tayada waqtiga-dhabta ah.

5. Tayada Dhisida Fasalka Warshadaha

-

Naqshadaynta mootooyinka laba-geesoodka ah waxay kordhisaa waxtarka dhalaalka iyo xasilloonida.

-

Qaab dhismeedka farsamada adag wuxuu yareeyaa gariirka wuxuuna xaqiijiyaa adkeysiga muddada dheer.

Tilmaamaha Farsamada ee Mashiinka Daloolinta Robotiga

| Qaabka Qalabka | Jirka Robot | Ku celi Xaqiijinta Meelaynta | Dhererka dhexroorka | Madaxa Polishing Single Rotation | Madaxa Polishing Multi-Rotation | Qalab yar | Nooca ugu weyn ee giraangiraha | Daalaynta Madaxa Wareega | Jooji Isbadalka Degdega ah | Aaladda Is-habaynta | Madaxa Cabirka Iskudubarid | Korjoogteynta Dhumucda onlaynka ah | Platform Control Tirooyinka |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IRP500S | Staubli TX2-90L | ± 0.04mm / kala duwanaansho buuxda | Φ50 ~ Φ500mm | √ | × | √ | √ | √ | × | ○ | ○ | ○ | ○ |

| IRP600S | Staubli TX2-140 | ± 0.05mm / kala duwan oo buuxa | Φ50 ~ 600mm | √ | × | √ | √ | √ | × | ○ | ○ | ○ | ○ |

| IRP800S | Staubli TX2-160 | ± 0.05mm / kala duwan oo buuxa | Φ80 ~ 800mm | √ | √ | √ | √ | √ | ○ | ○ | ○ | ○ | ○ |

| IRP1000S | Staubli TX200/L | ± 0.06mm / kala duwanaansho buuxda | Φ100 ~ Φ1000mm | √ | ○ | √ | √ | √ | ○ | ○ | ○ | ○ | ○ |

| IRP1000A | ABB IRB6700-200 / 2.6 | ± 0.1mm / kala duwanaansho buuxda | Φ100 ~ Φ1000mm | √ | ○ | √ | √ | √ | ○ | ○ | ○ | ○ | ○ |

| IRP2000A | ABB IRB6700-150 / 3.2 | ± 0.1mm / kala duwanaansho buuxda | Φ200 ~ Φ2000mm | √ | ○ | √ | √ | √ | × | × | × | ○ | ○ |

| IRP2000AD | ABB IRB6700-150 / 3.2 | ± 0.1mm / kala duwanaansho buuxda | Φ200 ~ Φ2000mm | √ | ○ | √ | √ | √ | × | × | × | ○ | ○ |

FAQ – Robot Polishing Machine

1. Waa maxay noocyada qalabka shaqada ee mashiinka polishing machine-ka uu xamili karo?

Mashiinka dhalaalka robot-kayaga waxa uu taageeraa qaabab iyo sagxadaha kala duwan, oo ay ku jiraan fidsan, qaloocan, wareegsan, qaab xor ah, iyo muuqaalo isku dhafan. Waxay ku habboon tahay qaybaha indhaha, caaryada saxda ah, sagxadaha birta ah, iyo codsiyada kale ee saxnaanta sare leh.

2. Waa maxay faraqa u dhexeeya meerto-wareejin-kaliya iyo madax-dambiyeedka-wareeg-badan?

-

Madaxa Polishing Single Rotation: Qalabku wuxuu ku wareegaa hareeraha hal dhidib, oo ku habboon dhamaystirka dusha sare ee caadiga ah iyo ka saarida alaabta xawaaraha sare leh.

-

Madaxa Polishing Multi-Rotation: Qalabku waxa uu isku daraa wareeg iyo is-wareejin (orbiting), taas oo awood u siinaysa in badan oo lebbis lebbisan dusha qaloocan iyo kuwa aan joogto ahayn.

3. Waa maxay dhexroorka farsamaynta ugu badan?

Iyadoo ku xiran qaabka:

-

Moodooyinka is haysta (tusaale, IRP500S) gacantaΦ50-Φ500mm.

-

Moodooyinka waaweyn (tusaale, IRP2000AD) waxay qabtaan ilaaΦ2000mm.

Annaga

XKH waxay ku takhasustay horumarinta tignoolajiyada sare, wax soo saarka, iyo iibinta muraayadaha indhaha ee gaarka ah iyo agabka cusub ee crystal. Badeecadahayadu waxay u adeegaan qalabka elektarooniga ah, elektiroonigga macaamiisha, iyo militariga. Waxaan bixinaa qaybaha indhaha ee Sapphire, daboolka muraayadda taleefanka gacanta, Ceramics, LT, Silicon Carbide SIC, Quartz, iyo maraqyada crystal semiconductor. Iyada oo leh khibrad xirfad leh iyo qalab-goynta, waxaan ku fiicanahay habaynta badeecada aan caadiga ahayn, annagoo higsanayna inaan noqono hormuudka agabka optoelectronic shirkad farsamo sare leh.