Qalabka tignoolajiyada Microjet laser wafer goynta qalabka SiC

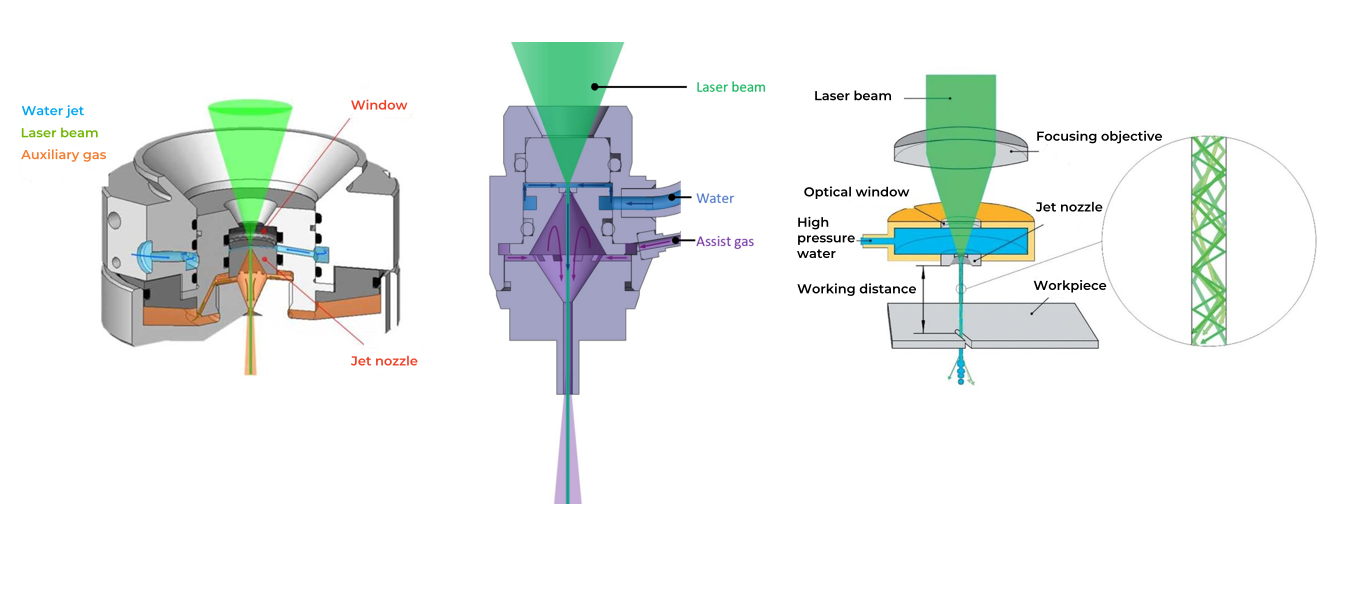

Mabda'a shaqada:

1. Isku-xidhka Laser: Laysarka garaaca (UV/cagaaran/infrared) ayaa diiradda lagu saaray gudaha jetka dareeraha ah si loo sameeyo kanaalka gudbinta tamarta deggan.

2. Hanuuninta dareeraha: jet-xawaaraha sare leh (heerka socodka 50-200m/s) qaboojinta aagga warshadaynta iyo qaadista qashinka si looga fogaado kulaylka iyo wasakhowga.

3. Ka saarida walxaha: Tamarta laysarka waxay sababtaa saamaynta cavitation ee dareeraha si loo gaaro habaynta qabow ee walxaha (aagga kulaylka saameeya <1μm).

4. Xakamaynta firfircoon: hagaajinta wakhtiga dhabta ah ee cabbirada laysarka (awoodda, soo noqnoqda) iyo cadaadiska jet si loo daboolo baahiyaha qalabka iyo qaababka kala duwan.

Halbeegyada muhiimka ah:

1. Awoodda laser: 10-500W (la hagaajin karo)

2. Dhexroor Jet: 50-300μm

3.Machining saxnaanta: ± 0.5μm (goyn), qoto dheer ilaa baaxadda saamiga 10: 1 (dalool)

Faa'iidooyinka farsamada:

(1) Ku dhawaad eber waxyeelada kulaylka

- Qaboojinta jet dareere ah ayaa koontaroolaysa aagga kulaylka saameeyay (HAZ) ilaa ** <1μm**, iyada oo iska ilaalinaysa dildilaaca yar yar ee ay sababto farsamaynta laser-ka caadiga ah (HAZ badanaa waa> 10μm).

(2) Mashiinka saxda ah ee aadka u sarreeya

- Saxnaanta goynta / qodista ilaa **± 0.5μm ***, qallafsanaanta cidhifka Ra<0.2μm, waxay yaraynaysaa baahida suufka xiga.

- Taageer hab-dhismeedka qaab-dhismeedka 3D adag (sida godadka conical, boosaska qaabaysan).

(3) Waafaqid walxaha ballaaran

- Qalab adag oo jilicsan: SiC, sapphire, galaas, ceramics (hababka dhaqameed way fududahay in la burburiyo).

- Qalabka xasaasiga ah ee kulaylka: polymers, unugyo noole (khatar ma laha denaturation kulaylka).

(4) Ilaalinta deegaanka iyo hufnaanta

- Wax wasakh ah ma leh, dareeraha dib ayaa loo warshadeyn karaa oo waa la sifeyn karaa.

- 30% -50% korodhka xawaaraha wax-qabadka (marka loo eego machining).

(5) Xakamaynta caqliga

- Meelaynta muuqaalka isku dhafan iyo hagaajinta halbeegga AI, dhumucda walxaha la qabsiga iyo cilladaha.

Tilmaamaha Farsamada:

| Mugga Countertop | 300*300*150 | 400*400*200 |

| dhidibka toosan ee XY | Matoorka toosan. Matoorka toosan | Matoorka toosan. Matoorka toosan |

| dhidibka toosan Z | 150 | 200 |

| Meelaynta saxnaanta μm | +/-5 | +/-5 |

| Saxnaanta meelaynta soo noqnoqda μm | +/-2 | +/-2 |

| Dardargelinta G | 1 | 0.29 |

| Xakamaynta tirada | 3 dhidib /3+1 dhidib /3+2 dhidib | 3 dhidib /3+1 dhidib /3+2 dhidib |

| Nooca xakamaynta tirada | DPSS Nd:YAG | DPSS Nd:YAG |

| Mawjada dhererka nm | 532/1064 | 532/1064 |

| Awood la qiimeeyay W | 50/100/200 | 50/100/200 |

| Diyaaradda biyaha | 40-100 | 40-100 |

| Bar cadaadiska sanbabada | 50-100 | 50-600 |

| Cabbirrada (qalabka mashiinka) (ballaadhka * dhererka * dhererka) mm | 1445*1944*2260 | 1700*1500*2120 |

| Cabbirka (xakamaynta golaha) (W * L * H) | 700*2500*1600 | 700*2500*1600 |

| Miisaanka (qalabka) T | 2.5 | 3 |

| Miisaanka (xakamaynta kabinada) KG | 800 | 800 |

| Kartida habaynta | Qalafsanaanta dusha sare ee Ra≤1.6um Xawaaraha furitaanka ≥1.25mm/s Goynta wareegga ≥6mm/s Xawaaraha goynta toosan ≥50mm/s | Qalafsanaanta dusha sare ee Ra≤1.2um Xawaaraha furitaanka ≥1.25mm/s Goynta wareegga ≥6mm/s Xawaaraha goynta toosan ≥50mm/s |

| Wixii gallium nitride crystal, agabka farqiga u dhexeeya band ultra-ballaaran (dheeman/Gallium oxide), aerospace qalab gaar ah, LTCC kaarboon substrate dhoobada, photovoltaic, crystal scintillator iyo qalabka kale ee processing. Fiiro gaar ah: Awoodda habayntu way kala duwan tahay iyadoo ku xidhan sifooyinka alaabta

| ||

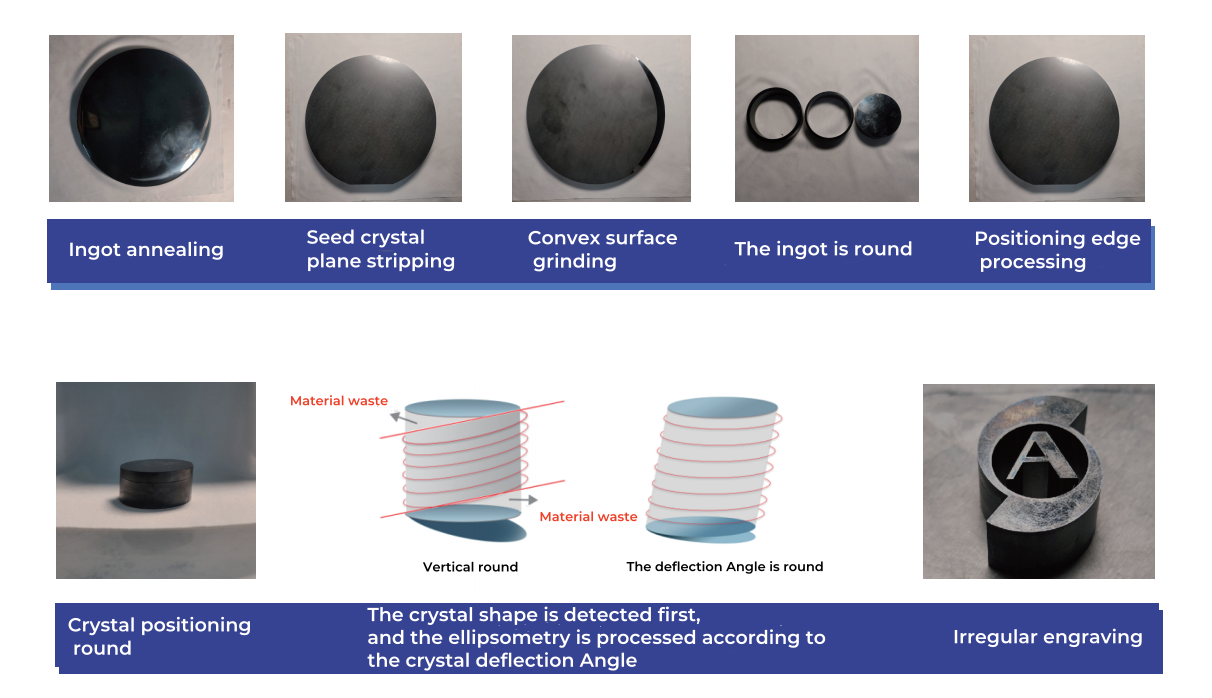

Kiiska habaynta:

Adeegyada XKH:

XKH waxay bixisaa taageero buuxda oo buuxda oo ah adeegga wareegga nolosha ee qalabka tignoolajiyada laser microjet, laga bilaabo horumarinta geedi socodka hore iyo la tashiga xulashada qalabka, ilaa dhexdhexaadinta nidaamka isdhexgalka nidaamka habaysan (oo ay ku jiraan isbarbardhigga gaarka ah ee isha laser, nidaamka jet iyo moduleka otomatiga), tababarka dambe ee hawlgalka iyo dayactirka iyo hagaajinta habka joogtada ah, habka oo dhan wuxuu ku qalabaysan yahay taageero koox farsamo; Iyada oo ku saleysan 20 sano ee waayo-aragnimada saxda ah ee farsamaynta, waxaan ku siin karnaa xalal hal-joojin ah oo ay ku jiraan xaqiijinta qalabka, soo-saarka wax-soo-saarka ballaaran iyo jawaab-celinta degdega ah ee iibka ka dib (24 saacadood oo taageero farsamo ah + kaydka qaybaha muhiimka ah) ee warshadaha kala duwan sida semiconductor iyo caafimaadka, iyo ballanqaad 12 bilood damaanad dheer iyo dayactirka nolosha iyo adeegga cusboonaysiinta. Hubi in qalabka macaamiishu ay had iyo jeer ilaaliyaan waxqabadka warshadaynta hogaaminaysa iyo xasiloonida.

Jaantus faahfaahsan