LNOI Wafer (Lithium Niobate on Insulator) Isgaarsiinta Dareenka Electro-Optic Sare

Jaantus faahfaahsan

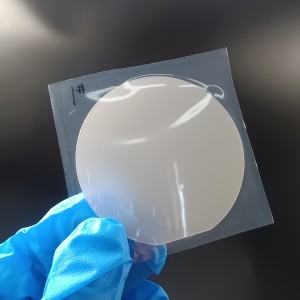

Dulmar

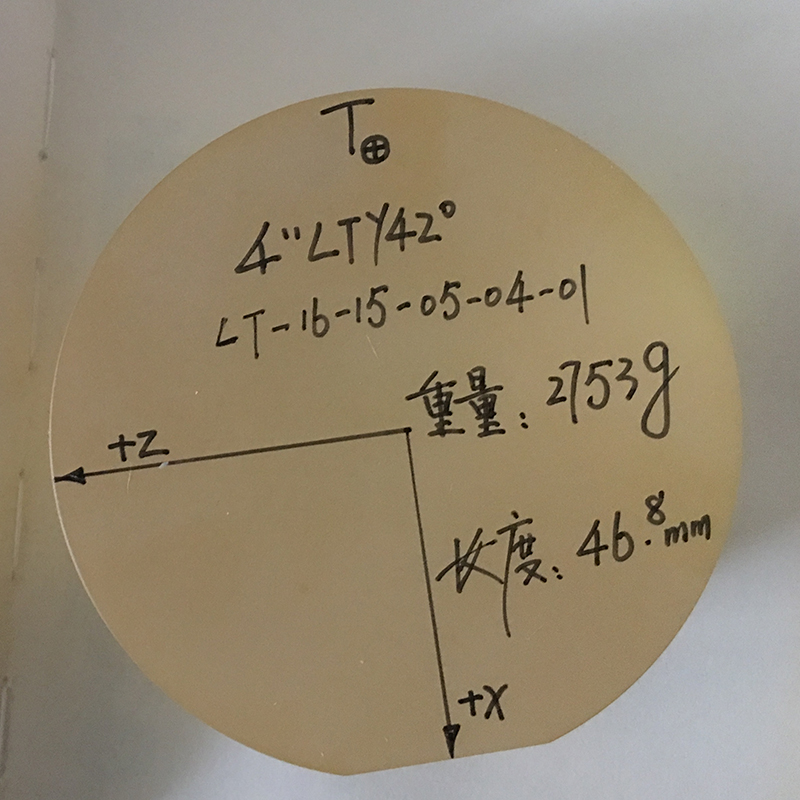

Gudaha sanduuqa wafer-ka waxaa ku yaal godad simmetrical ah, cabbiradoodu waa kuwo si adag u lebbisan si ay u taageeraan labada dhinac ee waferka. Sanduuqa kristanta guud ahaan waxa uu ka samaysan yahay walxo PP balaastiig ah oo adkaysi u leh heerkulka, xidhashada iyo korontada taagan. Midabada kala duwan ee lagu daro ayaa loo isticmaalaa in lagu kala saaro qaybaha habka biraha ee wax soo saarka semiconductor. Sababtoo ah cabbirka muhiimka ah ee yar yar ee semiconductors, qaababka cufan, iyo shuruudaha cabbirka walxaha aadka u adag ee wax soo saarka, sanduuqa waferka waa in la dammaanad qaadaa jawi nadiif ah si loogu xiro sanduuqa falcelinta microenvironment ee mashiinnada wax soo saarka kala duwan.

Habka Farsamaynta

Samaynta waferrada LNOI waxay ka kooban tahay dhowr tillaabo oo sax ah:

Talaabada 1: Beerista Helium IonIonyada Helium waxaa lagu dhex geliyaa kiristaalo badan oo LN ah iyadoo la isticmaalayo qalab-galiyaha ion. Iions-yadani waxay ku hoydaan qoto dheer oo gaar ah, samaynta diyaarad daciif ah oo ugu dambeyntii fududeyn doonta goosashada filimka.

Tallaabada 2: Samaynta Substrate-ka SaldhiggaSilikoon ama wafer gaar ah ayaa oksaydhaysan ama lagu dahaadhay SiO2 iyadoo la isticmaalayo PECVD ama oksaydhka kulaylka. Oogada sare ayaa loo qorsheeyey isku xidhka ugu fiican.

Talaabada 3: Ku xidhida LN ilaa SubstrateKaristaanka LN-ka-aan-ku- beeran ayaa la rogaa oo lagu dhejiyaa waferka salka iyadoo la adeegsanayo isku-xidhka wafer-ka tooska ah. Goobaha cilmi-baarista, benzocyclobutene (BCB) ayaa loo isticmaali karaa sidii koollo si loo fududeeyo isku-xidhka xaaladaha adag ee yar.

Talaabada 4: Daawaynta Kulaylka iyo Kala Saarida FilimkaAnnealing waxay kicisaa samaynta xumbo qoto dheer oo la beeray, taas oo awood u siinaysa kala soocida filimka khafiifka ah (lakabka sare ee LN) iyo tirada badan. Xoog makaanik ah ayaa loo isticmaalaa si loo dhamaystiro exfoliation.

Talaabada 5: Tooshka dusha sarePolishing Mechanical Chemical (CMP) ayaa lagu dabaqaa si loo simo dusha sare ee LN, iyada oo hagaajinaysa tayada indhaha iyo soosaarka qalabka.

Qiyaasaha Farsamada

| Qalab | Muuqaal Darajo LiNbO3 wafes (White or Madow) | |

| Curie Heerkulka | 1142 ± 0.7 ℃ | |

| Goynta Xagasha | X/Y/Z iwm | |

| Dhexroorka/xajmiga | 2"/3"/4" ±0.03mm | |

| Tol (±) | <0.20 mm ±0.005mm | |

| Dhumucda | 0.18 ilaa 0.5mm ama ka badan | |

| Asal ahaan fidsan | 16mm/22mm/32mm | |

| TTV | <3μm | |

| Qaansada | -30 | |

| Warp | <40μm | |

| Hanuuninta fidsan | Dhammaan la heli karo | |

| Dusha sare Nooca | Dhinac Keli ah oo La Sifeeyay | |

| La sifayn dhinac Ra | <0.5nm | |

| S/D | 20/10 | |

| Cidhif Shuruudaha | R=0.2mm Nooca C or Bullnose | |

| Tayada | Bilaash of dildilaac (xumbo iyo ka mid noqoshada) | |

| Muuqaal doped | Mg/Fe/Zn/MgO iwm waayo indhaha darajo LN wafers per codsaday | |

| Wafer Dusha sare Shuruudaha | Tilmaanta refractive | No=2.2878/Ne=2.2033 @632nm wavelength/prism coupler method. |

| faddarayn, | Midna | |

| Qaybaha c>0.3μ m | <=30 | |

| xoqid, xoqid | Midna | |

| Cilad | Ma jiraan dildilaacyo gees ah, xoqan, calaamado miinshaar, wasakh | |

| Baakadaha | Qty/sanduuqa wafer | 25pcs halkii sanduuq |

Isticmaal Kiisas

Iyada oo ay ugu wacan tahay wax-qabadkeeda, LNOI waxa loo adeegsadaa warshado badan:

Sawir-qaadista:Modulators is haysta, multiplexers, iyo photonic wareegyada.

RF/Acoustics:Modulators Acousto-optic, filtarrada RF.

Xisaabinta Quantum:Isku-dariyeyaasha soo noqnoqda ee aan tooska ahayn iyo soo-saareyaasha sawir-qaadayaasha.

Difaaca & Hawada:Gyros indhaha-khasaare hooseeya, aaladaha beddela soo noqnoqda.

Qalabka Caafimaadka:Biosensors indhaha iyo shaybaarrada calaamadaha soo noqnoqda ee sarreeya.

FAQ

S: Waa maxay sababta LNOI looga door biday SOI ee hababka indhaha?

A:LNOI waxa ay leedahay isku xidhayaasha korantada-optic-ga ka sarreeya iyo kala duwanaansho hufan oo ballaadhan, taas oo u oggolaanaysa waxqabadka sare ee wareegyada sawir-qaadista.

S: CMP ma qasab baa ka dib kala qaybsanaan?

A:Haa Dusha sare ee LN waa mid qallafsan ka dib ion-slicing waana in la sifeeyaa si loo buuxiyo tilmaamaha heerka-aragga.

S: Waa maxay xajmiga ugu badan ee wafer ee la heli karo?

A:Waferrada ganacsiga ee LNOI waa ugu horrayn 3” iyo 4”, in kasta oo alaab-qeybiyeyaasha qaarkood ay soo saarayaan 6” kala duwanaansho.

S: Lakabka LN dib ma loo isticmaali karaa kala qaybsanaanta ka dib?

A:Karistaanka saldhigga ah dib ayaa loo dami karaa oo dib loo isticmaali karaa dhowr jeer, inkastoo tayada ay hoos u dhici karto ka dib wareegyo badan.

S: Waferrada LNOI ma ku habboon yihiin habaynta CMOS?

A:Haa, waxaa loogu talagalay inay la jaanqaadaan hababka wax-soo-saarka semiconductor-ka caadiga ah, gaar ahaan marka substrate-ka silikon la isticmaalo.