Infrared Picosecond Dual-Platform Laser Qalabka Goynta ee muraayadaha indhaha/Quartz/Sapphire

Halbeegga ugu muhiimsan

| Nooca Laser | Infrared Picosecond |

| Cabbirka Platform | 700×1200 (mm) |

| 900×1400 (mm) | |

| Dhumucda Goynta | 0.03-80 (mm) |

| Xawaaraha Goynta | 0-1000 (mm/s) |

| Goynta Cirifka | <0.01 (mm) |

| Xusuusin: Cabbirka madal waa la beddeli karaa | |

Astaamaha Muhiimka ah

1.Ultrafast tignoolajiyada Laser-ka:

garaaca garaacyada gaagaaban ee heerka labaad (10⁻¹²) oo ay weheliso tignoolajiyada hagaajinta MOPA waxay gaadhaan cufnaanta ugu sarreysa>10¹² W/cm².

Mawjada Infrared (1064nm) waxa ay dhexda u gelisaa walxaha daah-furnaanta ah iyada oo loo marayo nuugista aan tooska ahayn, ka hortagga xoqitaanka dusha sare.

Nidaamka indhaha ee kala-duwan ee lahaanshaha leh ayaa isku mar wada abuura afar goobood oo wax-qabad oo madaxbannaan.

2.Nidaamka Isku-xidhka Labada-Station:

Marxaladaha mootada toosan ee laba-geesoodka ah ee Granite-base ( saxnaanta meelaynta: ± 1μm).

Waqtiga beddelka saldhigga <0.8s, taasoo awood u siinaysa hawlo isbarbar socda "habayn-loading/ dejin".

· Xakamaynta heerkulka madaxa banaan (23±0.5°C) xaruntiiba waxay hubisaa xasiloonida mashiinada mudada dheer.

3. Xakamaynta habka caqliga leh:

Xogta walxaha isku-dhafan (200+ cabbir quraarad) oo si toos ah u dhigma cabbirka.

La socodka wakhtiga dhabta ah ee balasmaha ayaa si firfircoon u hagaajiya tamarta laysarka (xalinta hagaajinta: 0.1mJ).

Ilaalinta daahyada hawadu waxay yaraynaysaa dildilaaca cidhifka ah (<3μm).

Kiis arji caadi ah oo ku lug leh 0.5mm dhumucdiisuna waxay tahay sapphire dicing, nidaamku wuxuu gaaraa xawaare goyn ah 300mm/s oo leh cabbir jajab <10μm, taasoo ka dhigan hagaajinta waxtarka 5x ee hababka dhaqanka.

Ka-hortagga Faa'iidooyinka

1.Integrated dual-station nidaamka goynta iyo kala qaybinta hawl dabacsan;

2.Machining-xawaaraha sare ee joomatariyada adag waxay kor u qaadaysaa hufnaanta habka beddelka;

3.Taper-free geesaha goynta oo leh jajabka ugu yar (<50μm) iyo maaraynta badbaadada hawlwadeenka;

4. Kala-guurka aan kala go 'lahayn ee u dhexeeya qeexitaannada alaabta oo leh hawlgal dareen leh;

5. Kharashyada hawlgalka oo hooseeya, heerka waxsoosaarka sarreeya, habka isticmaalka-free iyo wasakhowga-free;

6.Zero Gene of slag, dareeraha qashinka ama biyaha wasakhda ah oo leh dammaanad dusha sare leh;

Muujinta muunada

Codsiyada caadiga ah

1.Waxsoosaarka Elektarooniga ah ee Macaamiisha:

Goynta saxda ah ee konturrada casriga ah ee muraayadda 3D ee casriga ah ( saxnaanta xagasha R: ± 0.01mm).

Qulqulka dalool-yar ee muraayadaha saacadda sapphire-ka (daloolka ugu yar: Ø0.3mm).

· Dhamaystirka aagagga gudbinta muraayadaha indhaha ee kamaradaha aan muuqan.

2.Waxsoosaarka Qaybaha indhaha:

· Mashiinka qaab-dhismeedka yar yar ee AR/VR muraayadaha muraayadaha (cabbirka muuqaalka ≥20μm).

Goynta xaglaha ah ee prisms quartz ee collimators laser (dulqaad xagalaha: ± 15").

Qaabaynta muuqaalka filtarrada infrared (gooynta taper <0.5°).

3. Baakadaha Semiconductor:

Dhalada dhexmarta (TGV) ee heerka wafer (dhinaca saamiga 1:10).

· Microchannel-ka oo ku xoqaya substrate-ka dhalooyinka ee jajabyada microfluidic (Ra <0.1μm).

Goynta soo noqnoqda-habaynta ee resonators MEMS quartz.

Samaynta daaqadaha indhaha ee LiDAR ee baabuurta, nidaamku wuxuu awood u siinayaa goynta muraayadda quartz-ka 2mm ee dhumucdiisuna tahay 89.5 ± 0.3 °, buuxinta shuruudaha tijaabada gariir-gariir baabuur.

Habraaca Codsiyada

Si gaar ah loogu farsameeyay goynta saxda ah ee jilicsan/qalabka adag oo ay ku jiraan:

1.Muraayadaha caadiga ah & muraayadaha indhaha (BK7, silica isku dhafan);

2. kiristaalo Quartz & substrates sapphire;

3. Dhalooyinka kuleylka leh & filtarrada indhaha

4. Substrates muraayadaha

Awood u leh goynta konturrada iyo qodista godka gudaha ee saxda ah (ugu yaraan Ø0.3mm)

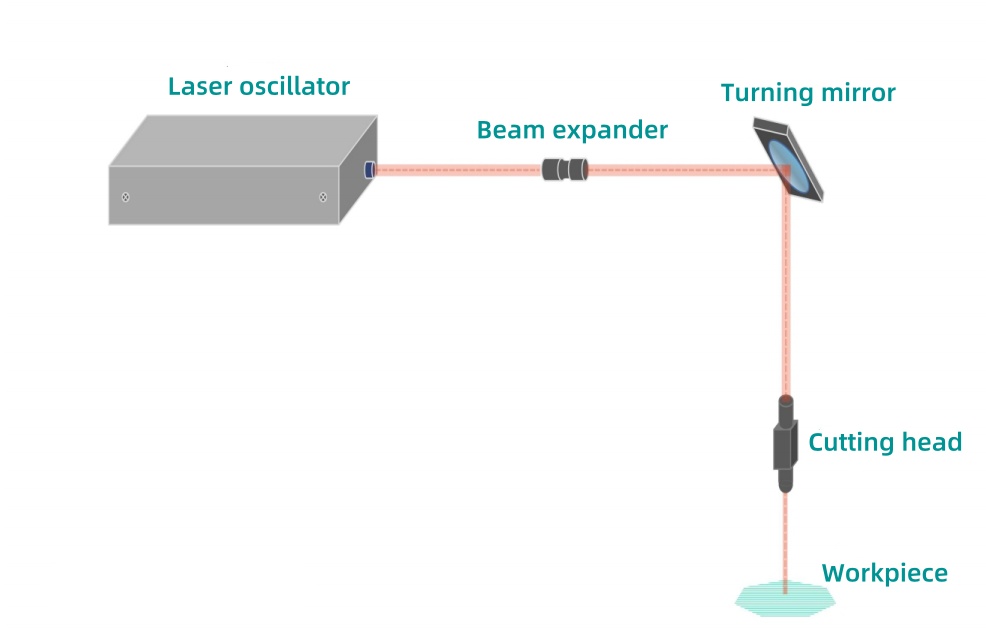

Mabda'a Goynta Laser

Laydhku waxa uu abuuraa garaacyo ultrashort leh tamar aad u saraysa taas oo la falgasha qaybta shaqada gudaha saacadaha femtosecond-to-picosecond. Inta lagu jiro faafinta iyada oo loo marayo maaddada, alwaaxdu waxay carqaladeysaa qaab-dhismeedkeeda walbahaarka si ay u sameyso godadka fiilo-yar ee cabbirka. Fogaanta daloolka la wanaajiyey waxay dhalisaa dildilaaca yar yar ee la kantaroolo, kaas oo ku daraya tignoolajiyada dillaaca si loo gaaro kala soocid sax ah.

Faa'iidooyinka Goynta Laser

1.Is-dhexgalka otomatiga sare (isku-dhafka goynta / shaqeynta isku-dhafka) oo leh isticmaalka tamarta hoose iyo hawlgalka fudud;

2.Non-xiriirka ka-hortagga awood awood gaar ah oo aan la heli karin iyada oo loo marayo hababka caadiga ah;

3. Hawlgalka bilaashka ah ee la isticmaali karo wuxuu yareeyaa kharashka socodka wuxuuna kor u qaadaa joogtaynta deegaanka;

4.Superior sax ah oo leh xagal eber taper iyo baabi'inta dhaawaca workpiece sare;

XKH waxay siisaa adeegyo dhammaystiran oo loogu talagalay nidaamyada goynta laser-ka, oo ay ku jiraan qaabeynta qaabeynta, horumarinta cabbirka habka gaarka ah, iyo xalal gaar ah oo codsi ah si loo buuxiyo shuruudaha wax-soo-saarka gaarka ah ee warshadaha kala duwan.