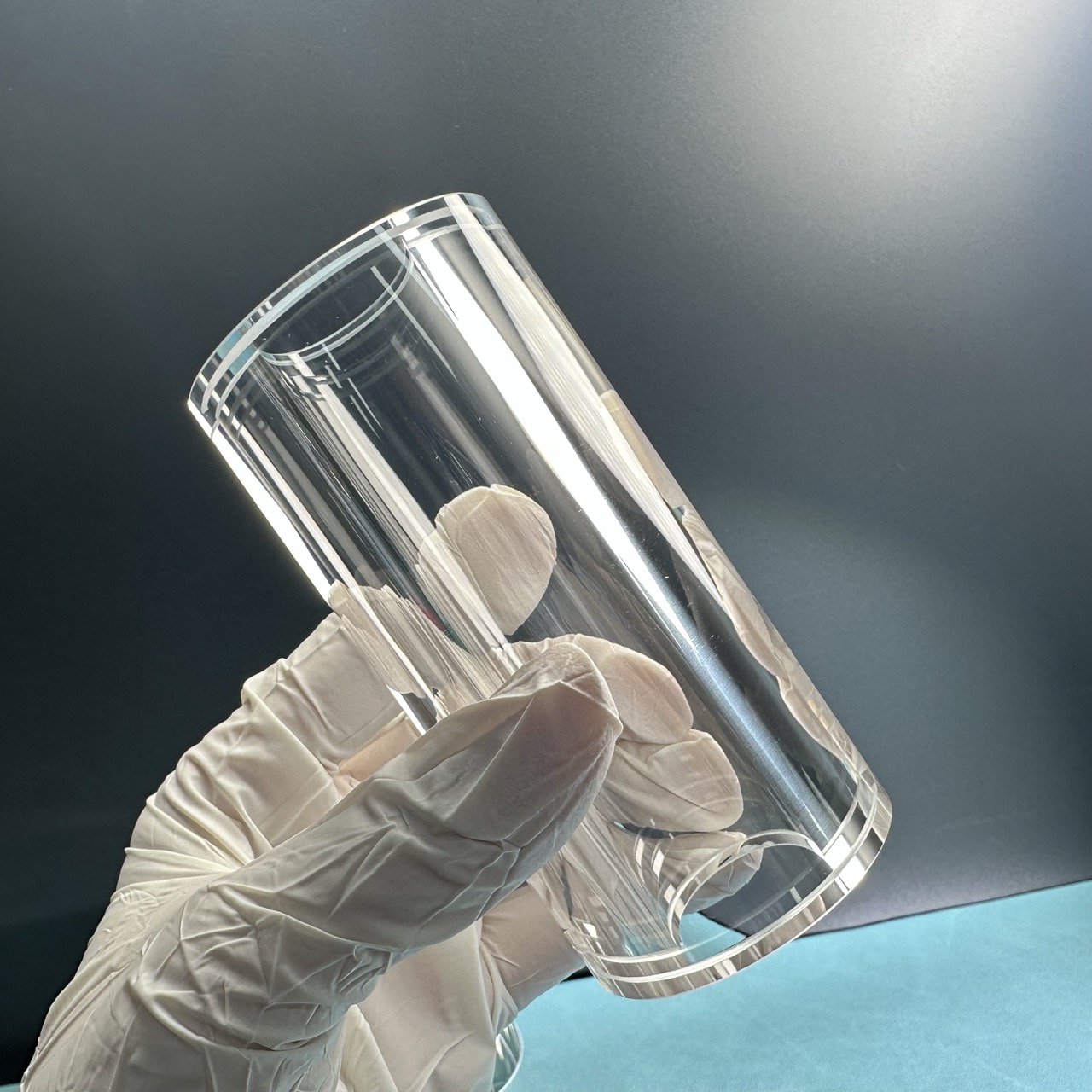

Wafers Quartz Fused Nadiif Sarreysa oo loogu talagalay Semiconductor, Codsiyada Sawirka Sawirka 2″4″6″8″12″

Jaantus faahfaahsan

Dulmarka muraayadda Quartz

Wafers Quartz ayaa ah laf-dhabarta aaladaha casriga ah ee aan la tirin karin ee kaxeeya adduunka casriga ah ee maanta. Laga soo bilaabo socodka taleefankaaga casriga ah ilaa laf dhabarta saldhigyada 5G, quartz waxay si aamusnaan ah u gudbisaa xasilloonida, nadiifnimada, iyo saxda ah ee looga baahan yahay waxqabadka sare ee elektiroonigga ah iyo sawir-qaadista. Hadday taageerto wareegyada dabacsan, awoodsiinta dareemayaasha MEMS, ama samaynta aasaaska xisaabinta tirada, sifooyinka gaarka ah ee quartz ayaa ka dhigaya lagama maarmaan dhammaan warshadaha.

"Fused Silica" ama "Fused Quartz" oo ah wejiga amorphous ee quartz (SiO2). Marka la barbardhigo muraayadda borosilicate, silica isku dhafan ma laha wax lagu daro; sidaas darteed waxay ku jirtaa qaabkeeda saafiga ah, SiO2. Silica isku dhafan waxay leedahay gudbin sare oo ah infrared iyo ultraviolet spectrum marka la barbardhigo muraayadda caadiga ah. Silica la isku daray waxaa lagu soo saaraa dhalaalid iyo dib-u-xoojin ultrapure SiO2. Silica isku-dhafka ah ee loo yaqaan 'Synthetic Fused Silica' ee dhinaca kale waxa laga sameeyay horudhaca kiimikaad ee silikoon qani ku ah sida SiCl4 kuwaas oo gaas lagu sameeyay ka dibna oksaydh lagu sameeyay jawiga H2 + O2. Boodhka SiO2 ee lagu sameeyay kiiskan wuxuu ku darsamay silica substrate. Dabaqyada silica ee isku dhafan ayaa la gooyaa maraqa ka dib markaa maraqyada waa la nadiifiyaa.

Tilmaamaha Muhiimka ah iyo Faa'iidooyinka Quartz ee Waferka Dhalada

-

Nadiif-sare aadka u sarreeya (≥99.99% SiO2)

Ku habboon semiconductor-ka aadka u nadiifka ah iyo hababka sawir-qaadista halkaasoo wasakheynta walxaha ay tahay in la yareeyo. -

Kala Duwanka Hawlgelinta Kulaylka Balaadhan

Waxay ilaalisaa daacadnimada qaab dhismeedka heer kulka cryogenic ilaa in ka badan 1100°C iyada oo aan gariirin ama hoos u dhicin. -

Gudbinta UV iyo IR heer sare ah

Waxay ka keentaa hufnaan muuqaal oo heersare ah oo ka imanaya ultraviolet qoto dheer (DUV) iyada oo u sii marinaysa infrared-ku dhow (NIR), taasoo taageerta codsiyada saxda ah ee indhaha. -

Iskuxidhka Balaadhinta kulaylka Hoose

Waxay xoojisaa xasiloonida cabbirka ee hoos yimaada isbedbedelka heerkulka, yaraynta walbahaarka iyo hagaajinta isku halaynta habka. -

Iska caabinta Kiimikada Sare

Asiidhyada, alkalisyada, iyo dareerayaasha badankooda oo aan firfircoonayn - taasoo ka dhigaysa mid ku habboon bay'adaha dagaalka kimikalka ah. -

Dusha Dhammaystir Dabacsanaanta

Lagu heli karo dhammays sifaysan aadka u jilicsan, hal dhinac ah ama laba-dhinac ah, oo la socon kara sawir-qaadista iyo shuruudaha MEMS.

Habka wax soo saarka ee Wafer Quartz Glass

Waferrada quartz fused waxaa lagu soo saaraa tillaabooyin taxane ah oo la kantaroolay oo sax ah:

-

Xulashada Qalabka Ceyriinka

Xulashada quartz dabiici ah oo nadiif ah oo sarreeya ama ilaha SiO₂ synthetic. -

Dhalaalidda iyo isku-dhafka

Quartz waxa lagu dhalaaliya at ~2000°C foornooyinka korantada ee hoos yimaada jawiga kontoroolka ah si meesha looga saaro ku darida iyo goobooyinka. -

Block Samaynta

Silica dhalaalaysa waxaa lagu qaboojiyaa baloogyo adag ama maro adag. -

Wafer goyn

Dheeman sax ah ama miinshaar silig ah ayaa loo isticmaalaa in lagu gooyo jeexjeexyada maran wafer. -

Laabashada & Tooshka

Labada dusha sare waa fidsan yihiin oo waa la safeeyey si ay u buuxiyaan qeexida indhaha, dhumucda, iyo qallafsanaanta saxda ah. -

Nadiifinta & Kormeerka

Wafers waxaa lagu nadiifiyaa ISO Class 100/1000 qolal nadiif ah waxaana lagu sameeyaa baaritaan adag oo ku saabsan cilladaha iyo u hoggaansanaanta cabbirka.

Guryaha waferka Quartz Glass

| gaar ah | unug | 4" | 6" | 8" | 10" | 12" |

|---|---|---|---|---|---|---|

| Dhexroor / cabbir (ama afar gees ah) | mm | 100 | 150 | 200 | 250 | 300 |

| Dulqaadasho (±) | mm | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Dhumucda | mm | 0.10 ama ka badan | 0.30 ama ka badan | 0.40 ama ka badan | 0.50 ama ka badan | 0.50 ama ka badan |

| Guriga tixraaca aasaasiga ah | mm | 32.5 | 57.5 | Nus darajo | Nus darajo | Nus darajo |

| LTV (5mm×5mm) | μm | <0.5 | <0.5 | <0.5 | <0.5 | <0.5 |

| TTV | μm | < 2 | <3 | <3 | < 5 | < 5 |

| Qaansada | μm | ±20 | ±30 | ±40 | ±40 | ±40 |

| Warp | μm | ≤ 30 | ≤ 40 | ≤ 50 | ≤ 50 | ≤ 50 |

| PLTV (5mm×5mm) <0.4μm | % | ≥95% | ≥95% | ≥95% | ≥95% | ≥95% |

| Wareega cidhifka | mm | Waafaqsan SEMI M1.2 Standard / tixraac IEC62276 | ||||

| Nooca Dusha sare | Dhinac Keli Ah Oo La Sifeeyay/Laba Dhinac Oo La Sifeeyay | |||||

| Dhanka Ra | nm | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| Shuruudaha dhinaca dambe | μm | guud 0.2-0.7 ama la habeeyey | ||||

Quartz vs. Qalabka kale ee Daah-furnaanta

| Hanti | Dhalada Quartz | Dhalada Borosilicate | Sapphire | Muraayadaha caadiga ah |

|---|---|---|---|---|

| Heer kulka ugu Sareeya | ~1100°C | ~ 500°C | ~2000°C | ~200°C |

| Gudbinta UV | Aad u fiican (JGS1) | Miskiin | Wacan | Aad u liita |

| Iska caabinta Kiimikada | Aad u fiican | Dhexdhexaad | Aad u fiican | Miskiin |

| daahirnimo | Aad u sarreeya | Hooseeyo ilaa dhexdhexaad | Sare | Hoose |

| Balaadhinta kulaylka | Aad u hooseeya | Dhexdhexaad | Hoose | Sare |

| Qiimaha | Dhexdhexaad ilaa sare | Hoose | Sare | Aad u hooseeya |

FAQ ee Quartz Glass Wafer

Q1: Waa maxay faraqa u dhexeeya quartz fused iyo silica la isku daray?

In kasta oo labaduba ay yihiin qaabab amorphous ah oo SiO₂ ah, quartz fused caadi ahaan waxay ka soo jeedaan ilaha quartz ee dabiiciga ah, halka silica la isku daray si farsamaysan loo soo saaray. Waxqabad ahaan, waxay bixiyaan waxqabad la mid ah, laakiin silica isku dhafan ayaa laga yaabaa inay yeelato daahirnimo wax yar ka sarreeya iyo isku-midnaanta.

Q2: Waferrada quartz-ka la isku daray ma lagu isticmaali karaa deegaan-vacuum-sare?

Haa Sababo la xiriira sifooyinkooda gaaska hooseeya iyo caabbinta kulaylka sare, waferrada quartz fused waxay aad ugu fiican yihiin nidaamyada faakuumka iyo codsiyada hawada sare.

Q3: Waferradani miyay ku habboon yihiin codsiyada laser-ka qoto dheer ee UV?

Dhab ahaantii. Quartz Fused wuxuu leeyahay gudbin sare ilaa ~ 185 nm, taasoo ka dhigaysa mid ku habboon DUV optics, maaskaro lithography, iyo nidaamyada laser excimer.

Q4: Miyaad taageertaa samaynta wafer-ka caadiga ah?

Haa Waxaan bixinaa habayn buuxda oo ay ku jiraan dhexroorka, dhumucda, tayada dusha sare, dabaqyo/notches, iyo naqshadaynta laysarka, oo ku salaysan shuruudaha codsigaaga gaarka ah.

Annaga

XKH waxay ku takhasustay horumarinta tignoolajiyada sare, wax soo saarka, iyo iibinta muraayadaha indhaha ee gaarka ah iyo agabka cusub ee crystal. Badeecadahayadu waxay u adeegaan qalabka elektarooniga ah, elektiroonigga macaamiisha, iyo militariga. Waxaan bixinaa qaybaha indhaha ee Sapphire, daboolka muraayadda taleefanka gacanta, Ceramics, LT, Silicon Carbide SIC, Quartz, iyo maraqyada crystal semiconductor. Iyada oo leh khibrad xirfad leh iyo qalab-goynta, waxaan ku fiicanahay habaynta badeecada aan caadiga ahayn, annagoo higsanayna inaan noqono hormuudka agabka optoelectronic shirkad farsamo sare leh.