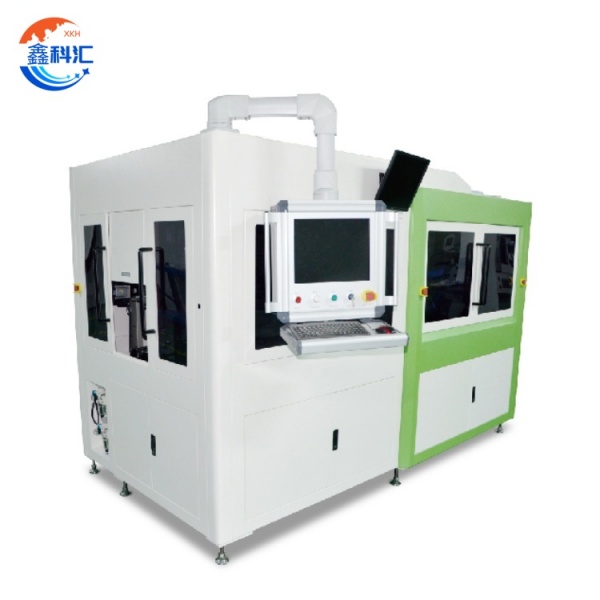

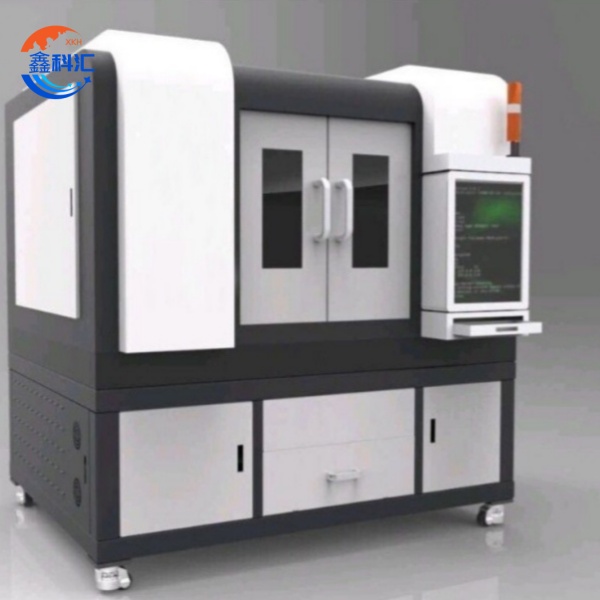

Mashiinka qodista laysarka ee saxda ah ee saxda ah ee sapphire dhoobada alaabta dhagaxa leh ee daloolista godka

Hordhac Product

Qalabka lagu dabaqi karo: Ku habboon birta dabiiciga ah, birta polycrystalline, ruby, sapphire, copper, ceramics, rhenium, birta aan lahayn, birta kaarboon, birta daawaha iyo kuwa kale ee adag, qalabka heerkulka sare u adkaysta ee qaababka kala duwan, dhexroorka, qoto dheer iyo qodista taper.

Xaaladaha shaqada

1. Waxay ku haboon tahay in lagu shaqeeyo heerkulka deegaanka ee 18 ℃-28 ℃ iyo qoyaan qaraabo ah 30% -60%.

2. Ku habboon sahayda tamarta laba-waji ah /220V/50HZ/10A.

3. Habee furayaasha buuxiya shuruudaha heerarka Shiinaha ee khuseeya. Haddi aanay jirin furahaas, adabtarada ku habboon waa in la bixiyaa.

4. Si ballaaran loo isticmaalo dhinta sawiridda siliga dheemanka, dhinta silig gaabis ah, dalool muffler, dalool irbad, dhagax-dhalasho, biibiile iyo warshado kale oo dalool ah.

Xuduudaha farsamada

| Magaca | Xogta | Shaqada |

| Mawjada maser indhaha | 354.7nm ama 355nm | Wuxuu go'aamiyaa qaybinta tamarta iyo awoodda dhexgalka ee laydhka laysarka, wuxuuna saameeyaa heerka nuugista walxaha iyo saamaynta farsamaynta. |

| Celceliska awoodda wax soo saarka | 10.0 / 12.0/15.0 w@40khz | Saamayn ku yeelashada waxtarka wax-ku-oolnimada iyo xawaaraha feedhitaanka, awoodda sare ee awoodda, si dhakhso ah xawaaraha wax-qabadka. |

| Ballaca garaaca | In ka yar 20ns@40KHz | Baaxadda garaaca wadnaha gaaban waxay yaraynaysaa aagga kulaylka saameeya, waxay wanaajisaa saxnaanta mashiinka, waxayna ka fogaanaysaa waxyeelada kulaylka ee walxaha. |

| Heerka soo noqnoqda garaaca wadnaha | 10 ~ 200KHz | Go'aami inta jeer ee gudbinta iyo waxtarka feerka ee laydhka laysarka, inta jeer ee soo noqnoqda, si dhakhso ah xawaaraha feerka. |

| tayada iftiinka indhaha | M² <1.2 | Alwaaxyada tayada sare leh waxay xaqiijinayaan saxnaanta qodista iyo tayada cirifka, yaraynta khasaaraha tamarta. |

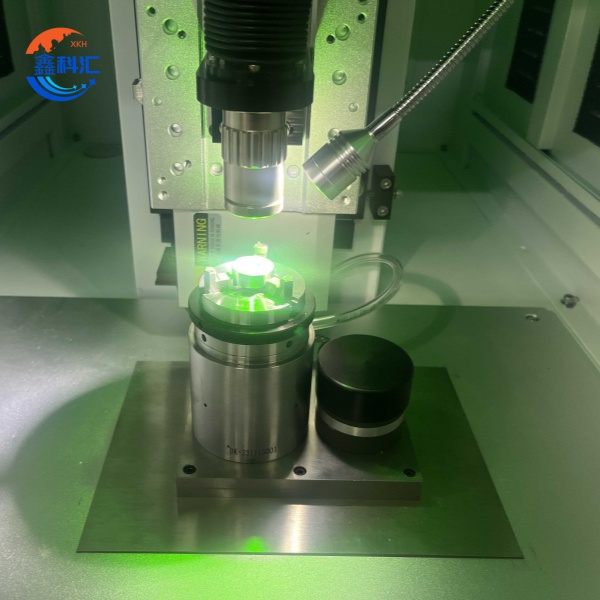

| Dhexroorka barta | 0.8±0.1mm | Go'aanso daloolka ugu yar iyo saxnaanta mishiinka, meesha yar, inta yar ee daloolka, ayaa sare u kacaysa saxnaanta. |

| xagal kala duwanaansho | In ka badan 90% | Awoodda diiradda iyo qoto-dheeraanta feerka ee laydhka laysarka ayaa saameeya. Inta yar ee xagasha kala duwanaanshiyaha, waa ay sii xoogaysanaysaa awoodda diiradda. |

| Elellipticity beam | In ka yar 3% RMS | Inta yar ee ellipticity, qaabka u dhow ee godku waa goobada, sare u kaca saxnaanta mashiinka. |

Awooda farsamaynta

Mashiinnada qodista laysarka ee saxda ah ee saxda ah waxay leeyihiin awoodo farsamayn oo awood leh waxayna daloolin karaan godadka dhawr mikron ilaa dhawr milimitir dhexroorka ah, qaabka, cabbirka, booska iyo xagasha godadka si sax ah ayaa loo kontarooli karaa. Isla mar ahaantaana, qalabku wuxuu taageeraa qodista 360-degree oo dhan ah, kaas oo dabooli kara baahida qodista ee qaababka iyo qaababka kala duwan ee adag. Intaa waxaa dheer, mashiinka feerka laysarka ee saxda ah ee saxda ah wuxuu kaloo leeyahay tayada cirifka wanaagsan iyo dhamaystirka dusha sare, godadka la warshadeeyay waa bilaash, ma dhalaalayaan gees, iyo dusha daloolku waa siman yahay oo siman.

Codsiga mashiinka feerka laysarka ee saxda ah:

1. Warshadaha Elektarooniga ah:

Sabuurada wareegga daabacan (PCB): waxaa loo isticmaalaa farsamaynta microhole si loo daboolo baahiyaha isku xirka cufnaanta sare.

Baakadaha Semiconductor: Feer godadka maraqa iyo alaabta baakadaha si loo hagaajiyo cufnaanta xirmada iyo waxqabadka.

2. Hawada sare:

Godadka qaboojinta daabka matoorka: Godad qaboojin yar ayaa lagu farsameeyaa garbaha superalloy si loo hagaajiyo waxtarka matoorka.

Ka-hortagga isku-dhafka ah: Qodista saxda ah ee saxda ah ee isku-dhafka fiber-carbon si loo hubiyo xoogga qaab-dhismeedka.

3. Qalabka Caafimaadka:

Qalabyada qalliinka ee ugu yar ee wax-ka-qabashada: Mashiinka godka yar yar ee qalabka qalliinka si loo hagaajiyo saxnaanta iyo badbaadada.

Habka gaarsiinta maandooriyaha: Feer godadka aaladda gaarsiinta dawada si loo xakameeyo heerka siideynta daroogada.

4. Samaynta Baabuurta:

Nidaamka duritaanka shidaalka: Makiinada godad yar-yar oo ku yaal tuubada duritaanka shidaalka si kor loogu qaado saamaynta atomization shidaalka.

Wax-soo-saarka dareemayaasha: Ku qodida godad walxaha dareemayaasha si loo hagaajiyo dareenkiisa iyo xawaaraha jawaabta.

5. Qalabka indhaha:

Xidhiidhiyaha fiber optic: Machining microholes ee xidhiidhka fiber indhaha si loo hubiyo tayada gudbinta signalada.

Filterka indhaha: Feer godadka shaandhada indhaha si aad u gaadho xulashada mawjada dhererka gaarka ah.

6. Mashiinada saxda ah:

Caaryada saxda ah: Makiinada microholes ee caaryada si loo hagaajiyo waxqabadka iyo nolosha adeegga caaryada.

Qaybaha yaryar: Feer godadka qaybaha yar yar si ay u daboolaan baahiyaha kulan sax ah oo sarreeya.

XKH waxay bixisaa adeegyo dhammaystiran oo sax ah oo sax ah oo mashiinnada qodista laysarka ah, oo ay ku jiraan iibinta qalabka, taageerada farsamada, xalalka la habeeyey, rakibaadda iyo komishanka, tababarka hawlgalka iyo dayactirka iibka ka dib, iwm, si loo hubiyo in macaamiisha ay adeegsadaan taageero xirfadeed, hufan oo dhammaystiran.

Jaantus faahfaahsan