Mashiinka Calaamadaynta UV Laser Caag PCB Calaamadaynta Qabow Hawo La qaboojiyey 3W/5W/10W Ikhtiyaarada

Jaantus faahfaahsan

Hordhaca Mashiinka Calaamadaynta UV Laser

Mashiinka calaamadaynta laysarka UV waa qalab warshadeed oo sax ah oo aad u saraysa oo adeegsata laydhka laysarka ee ultraviolet, sida caadiga ah dhererkiisu yahay 355nm, si loo sameeyo calaamad aan xidhiidh iyo tafatiran oo aad u faahfaahsan, xardho, ama samaynta dusha sare ee agabyo kala duwan. Mashiinka noocan oo kale ah wuxuu ku shaqeeyaa iyada oo ku saleysan farsamada farsamaynta qabow, taas oo keenta saameynta kulaylka ugu yar ee walxaha bartilmaameedka ah, taas oo ka dhigaysa mid ku habboon codsiyada u baahan isbarbardhigga sare iyo curyaaminta walxaha ugu yar.

Calaamadaynta laysarka UV waxay si gaar ah waxtar ugu leedahay substrate-ka jilicsan sida balaastikada, dhalooyinka, ceramics, semiconductors, iyo biraha leh dahaar gaar ah. Laysarka ultraviolet wuxuu carqaladeeyaa curaarta molecular ee dusha sare halkii uu ka dhalaali lahaa walxaha, taasoo keenta calaamado siman, cad, oo joogto ah iyada oo aan waxyeello u geysan meelaha ku xiga.

Waad ku mahadsan tahay tayada alwaaxdeeda aadka u fiican iyo diiradda aadka u wanaagsan, calaamadeeyaha laser UV waxaa si weyn loogu isticmaalaa warshadaha sida elektiroonigga ah, aaladaha caafimaadka, hawada sare, baakadaha qurxinta, iyo wax soo saarka wareegga isku dhafan. Waxay xarri kartaa tirooyinka taxanaha ah, koodka QR, qoraal-yar, calaamado, iyo tilmaameyaal kale oo leh caddayn gaar ah. Nidaamka ayaa sidoo kale lagu qiimeeyaa dayactirkiisa hooseeya, kalsoonida sare, iyo awoodda lagu dhex geliyo khadadka wax-soo-saarka otomaatiga ah ee hawlgalka joogtada ah.

Mabaadi'da Shaqada ee UV Laser Marking Machine

Mashiinka calaamadaynta leysarka UV wuxuu ku shaqeeyaa iyadoo lagu saleynayo habka falcelinta sawir-kimikaad, ugu horrayn wuxuu ku tiirsan yahay laydhka tamarta sare ee ultraviolet si uu u jebiyo curaarta molecular ee dusha shay. Si ka duwan laysarka infrared-ka caadiga ah ee isticmaala tamarta kulaylka si ay u tirtiraan ama u dhalaaliyaan substrate-ka, laysarka UV waxay ku shaqeeyaan habka loo yaqaan "processing qabow." Tani waxay keenaysaa in walxaha laga saaro ama wax ka beddelka dusha sare oo leh aagagga kulaylka saameeyay dayacan.

Tiknoolajiyada xudunta u ah waxay ku lug leedahay leyssar dawladeed adag oo iftiimiya iftiinka mawjadaha dhererka salka (sida caadiga ah 1064nm), kaas oo markaa loo maro taxane ah kiristaalo aan toos ahayn si loo dhaliyo jiilka seddexaad ee harmonic (THG), taasoo keentay soosaarka ugu dambeeya ee hirarka 355nm. Mawjaddan gaaban ee dhererka gaaban waxay siinaysaa feejignaan sare iyo nuugista sare ee agabyo kala duwan, gaar ahaan kuwa aan biraha ahayn.

Marka laydhka laysarka ee UV-ga diirada saaraya uu la falgalo qaybta shaqada, tamarta sare ee photon waxay si toos ah u carqaladaysaa qaab dhismeedka molecular iyada oo aan la helin faafin kuleyl oo muhiim ah. Tani waxay u ogolaaneysaa in lagu calaamadiyo xalal sare oo ku saabsan substrate-ka kulaylka leh sida PET, polycarbonate, galaas, ceramics, iyo walxaha elektarooniga ah, halkaas oo laysarka dhaqameedku ay keeni karaan is-diritaan ama midab. Intaa waxaa dheer, nidaamka laser-ka waxaa lagu xakameynayaa sawir-qaadayaasha galvanometer-xawaaraha sare leh iyo software CNC, iyadoo la hubinayo saxnaanta heerka-yar ee saxda ah iyo soo celinta.

Paramete of UV Laser Marking Machine

| Maya | Halbeegga | Tilmaamid |

|---|---|---|

| 1 | Qaabka Mashiinka | UV-3WT |

| 2 | Dhererka Mawjadaha Laser | 355nm |

| 3 | Awoodda leysarka | 3W / 20KHz |

| 4 | Heerka soo noqnoqda | 10-200KHz |

| 5 | Calaamadaynta Range | 100mm × 100mm |

| 6 | Balaadhka laynka | ≤0.01mm |

| 7 | Calaamadaynta Qoto dheer | ≤0.01mm |

| 8 | Dabeecada ugu yar | 0.06mm |

| 9 | Xawaaraha calaamadaynta | ≤7000mm/s |

| 10 | Ku celi Xaqiijinta | ±0.02mm |

| 11 | Shuruudaha Awoodda | 220V/Hal-waji/50Hz/10A |

| 12 | Wadarta Awoodda | 1KW |

Codsiyada Mashiinnada Calaamadaynta UV Laser

Mashiinnada calaamadaynta laysarka ee UV ayaa si ballaaran looga soo qaatay warshado badan sababtoo ah saxnimadooda sare, saameynta kulaylka ugu yar, iyo la jaanqaadida agabyo kala duwan. Hoos waxaa ah meelaha muhiimka ah ee codsiga:

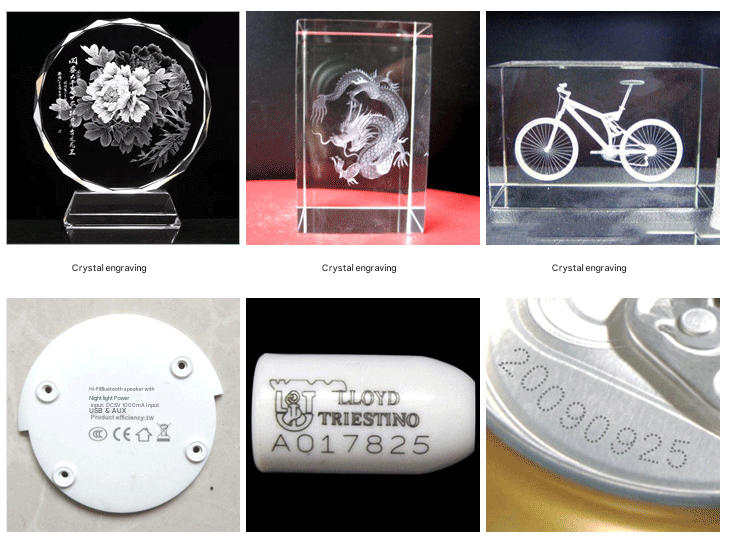

Warshadaha Elektrooniga & SemiconductorWaxaa loo istcimaalaa sumadeynta-yar ee chips-ka IC-ga, PCB-yada, xirayaasha, dareemayaasha, iyo qaybaha kale ee elegtarooniga ah. Laysarada UV waxay abuuri karaan xarfo ama xarfo aad u yar oo sax ah iyada oo aan waxyeello u geysan wareegyada jilicsan ama aysan keenin arrimo dhaqdhaqaaqa.

Qalabka Caafimaadka & Baakadaha: Ku habboon calaamadaynta saliingadaha, bacaha IV, tuubooyinka caaga ah, iyo polymers-daawaynta. Habka calaamadaynta qabowgu wuxuu hubinayaa in dhalmada la ilaaliyo oo aan wax u dhimayn daacadnimada qalabka caafimaadka.

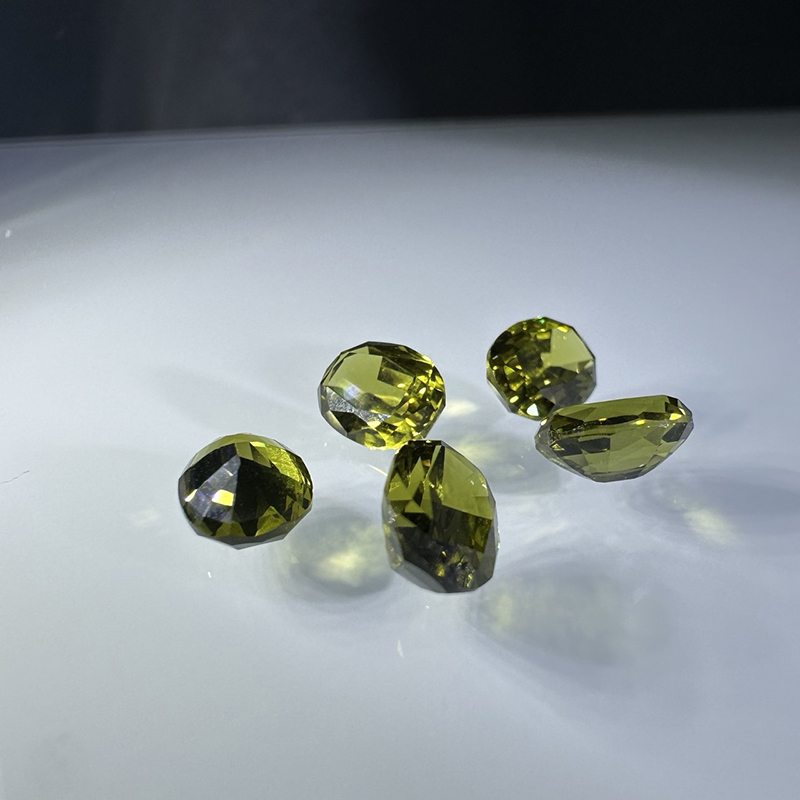

Dhalooyinka iyo Ceramics: UV lasers aad bay waxtar ugu leeyihiin xaradhka barcode, lambarada taxanaha ah, iyo qaababka qurxinta dhalooyinka dhalooyinka, muraayadaha, dhoobada dhoobada ah, iyo substrates quartz, taasoo ka tagaysa siman, geesaha aan dillaacin.

Qaybaha caagagga ahKu fiican in lagu calaamadiyo calaamadaha, nambarada dufcada, ama koodka QR ee ABS, PE, PET, PVC, iyo balaastikada kale. Laysarada UV waxay bixiyaan natiijooyin isbar-bardhig sare leh iyaga oo aan guban ama dhalaalin caagga.

Waxyaabaha la isku qurxiyo & Baakadaha CuntadaCodsaday weelal caag ah oo hufan ama midab leh, koofiyadaha, iyo baakadaha dabacsan si loo daabaco taariikhaha dhacayo, koodka dufcada, iyo calaamadeeyayaasha oo leh cadaymo sare.

Gawaarida iyo hawada hawada: Aqoonsiga qayb waara, qaraar sare leh, gaar ahaan dareemayaasha, dahaarka siliga, iyo daboolka iftiinka ee laga sameeyay walxaha xasaasiga ah.

Iyada oo ay ugu wacan tahay waxqabadkeeda sare ee calaamadaynta tafaasiisha wanaagsan iyo substrates-ka aan biraha ahayn, calaamadeeyaha laysarka UV wuxuu muhiim u yahay geeddi-socod kasta oo wax-soo-saar ah oo u baahan isku-hallayn, nadaafad, iyo calaamadayn aad u saxan.

Su'aalaha Inta badan La Isweydiiyo (FAQ) ee ku saabsan Mashiinnada Calaamadaynta UV Laser

Q1: Waa maxay agabyada ku habboon mashiinnada calaamadaynta laser UV?

A1: Calaamadaha laser UV waxay ku habboon yihiin noocyo kala duwan oo aan bir ahayn iyo qaar ka mid ah qalabka birta ah, oo ay ku jiraan balaastikada (ABS, PVC, PET), galaas, ceramics, wafers silicon, sapphire, iyo biraha dahaarka leh. Waxay si gaar ah si fiican ugu qabtaan substrates-kuleelka.

Q2: Sidee bay calaamadaynta laser UV uga duwan tahay fiber ama CO₂ calaamadaynta laser?

A2: Si ka duwan laysarka fiber-ka ama CO₂ ee ku tiirsan tamarta kulaylka, laysarka UV waxay isticmaalaan fal-celin sawir kiimiko ah si ay u calaamadiyaan dusha sare. Tani waxay keenaysaa tafaasiil fiican, dhaawac yar oo kulaylka, iyo calaamado nadiif ah, gaar ahaan alaabta jilicsan ama hufan.

Q3: Calaamadaynta UV laser ma joogto?

A3: Haa, calaamadaynta laser UV waxay abuurtaa isbarbardhig sare, waara, iyo calaamado u adkaysta kuwaas oo ku waaraya xaaladaha isticmaalka caadiga ah, oo ay ku jiraan soo-gaadhista biyaha, kulaylka, iyo kiimikooyinka.

Q4: Waa maxay dayactirka looga baahan yahay nidaamyada calaamadaynta laser UV?

A4: Laydhka UV wuxuu u baahan yahay dayactir yar. Nadiifinta joogtada ah ee qaybaha indhaha iyo filtarrada hawada, oo ay weheliso hubinta nidaamka qaboojinta saxda ah, waxay hubisaa waxqabadka muddada dheer xasilloon. Cimriga moduleka laysarka UV wuxuu caadi ahaan ka badan yahay 20,000 saacadood.

Q5: Ma lagu dhex dari karaa khadadka wax soo saarka ee iswada?

A5: Dhab ahaantii. Inta badan nidaamyada calaamadaynta laser UV waxay taageertaa isdhexgalka iyada oo loo marayo borotokoolka warshadaha ee caadiga ah (tusaale, RS232, TCP/IP, Modbus), taas oo u oggolaanaysa in lagu dhex geliyo hubka-robotka, gaadiidka qaada, ama nidaamyada wax soo saarka ee caqliga leh.

Annaga

XKH waxay ku takhasustay horumarinta tignoolajiyada sare, wax soo saarka, iyo iibinta muraayadaha indhaha ee gaarka ah iyo agabka cusub ee crystal. Badeecadahayadu waxay u adeegaan qalabka elektarooniga ah, elektiroonigga macaamiisha, iyo militariga. Waxaan bixinaa qaybaha indhaha ee Sapphire, daboolka muraayadda taleefanka gacanta, Ceramics, LT, Silicon Carbide SIC, Quartz, iyo maraqyada crystal semiconductor. Iyada oo leh khibrad xirfad leh iyo qalab-goynta, waxaan ku fiicanahay habaynta badeecada aan caadiga ahayn, annagoo higsanayna inaan noqono hormuudka agabka optoelectronic shirkad farsamo sare leh.