Waxqabadka Sare ee Alumina Ceramic End Effector (Gacanta Fargeetada) ee Semiconductor iyo Automation Nadiifinta

Jaantus faahfaahsan

Hordhac Product

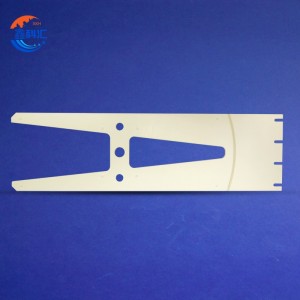

Alumina Ceramic End Effector, oo sidoo kale loo yaqaan gacanta fargeeto dhoobada ah ama gacanta dhoobada, waa qayb maarayn sax ah oo heer sare ah oo loogu talagalay nidaamyada iswada ee semiconductor, photovoltaic, bandhig guddi, iyo deegaan shaybaar oo nadiif ah. Waxaa loo naqshadeeyay inay bixiso degenaansho kulayl gaar ah, qallafsanaan farsamo, iyo iska caabin kiimikaad, iyadoo bixisa nadiif, la isku halayn karo, iyo gaadiid badbaado leh oo walxaha xasaasiga ah sida maraqa silikoon, substrates muraayadaha, iyo walxaha yaryar ee elektiroonigga ah.

Sida nooc ka mid ah saamaynta dhamaadka robotic, qaybtan dhoobada ah ayaa ah isdhexgalka ugu dambeeya ee u dhexeeya nidaamka otomaatiga ah iyo qaybta shaqada. Waxay ka ciyaartaa door muhiim ah wareejinta saxda ah, toosinta, rarista/dejinta, iyo meelaynta hawlaha qolalka nadiifka ah iyo meelaha faaruqa ah.

Dulmarka alaabta - Alumina Ceramic (Al₂O₃)

Alumina ceramic waa qalab farsamaysan oo aad u deggan oo kimikaad ahaan aan shaqaynayn oo loo yaqaan sifooyin farsamo iyo koronto oo aad u wanaagsan. Nadiifinta sare (≥ 99.5%) alumina loo isticmaalo kuwan wax qabadyada dhamaadka ah ayaa hubiya:

-

Adag (Mohs 9): Marka labaad kaliya dheeman, alumina waxay bixisaa iska caabin xad dhaaf ah.

-

Awoodda heerkulka sare: Wuxuu ilaaliyaa hufnaanta qaabdhismeedka ka sarreeya 1600°C.

-

Jilicsanaanta kiimikada: U adkaysta asiidhka, alkalis, dareerayaasha, iyo bay'adaha etching plasma.

-

dahaarka korontada: Iyada oo xoogga koronto-dhaleedka sare iyo luminta dielectric hooseeya.

-

Balaadhinta kulaylka hooseeya: Waxay xaqiijisaa xasilloonida cabbirka deegaanka baaskiil wadida kulaylka.

-

Jiil hooseMuhiim u ah waafaqid qolka nadiifka ah (Fasalka 10 ilaa fasalka 1000).

Astaamahani waxay ka dhigayaan dhoobada alumina ku habboon hawlgallada muhiimka ah ee warshadaha xasaasiga ah wasakhowga.

Codsiyada shaqeeya

Alumina ceramic end effector waxaa si balaadhan loogu qaataa hababka warshadaha ee teknoolajiyada sare leh, gaar ahaan meelaha alaabta macdan ama balaastikada ah ay ka gaabiyaan balaadhinta kulaylka, faddaraynta, ama arrimaha daxalka. Goobaha muhiimka ah ee codsiga waxaa ka mid ah:

- Wareejinta Semiconductor

- Nidaamyada rarista iyo dejinta sawir-qaadista

- Ku maaraynta substrate-ka muraayadda ee OLED iyo khadadka LCD

- Wareejinta wafer silikoon crystalline ee wax soo saarka unugyada cadceedda

- Kormeerka indhaha ama mikroelectronic ee tooska ah

- Tusaalaha gaadiidka ee shaybaarada falanqaynta ama biomedical

- Nidaamyada iswada ee deegaanka Vacuum

Awooddeeda ay ku fuliso iyada oo aan soo bandhigin qaybo ama kharash joogto ah ayaa ka dhigaysa mid aan looga maarmin hawlgallada saxda ah ee robotic ee otomaatiga qolka nadiifka ah.

Tilmaamaha Naqshadeynta & Habaynta

Waxyeele kasta oo dhammaadka dhoobada ah waxaa loo habeeyay inuu ku habboon yahay cudud gaar ah ama habka maaraynta waferka. Waxaan taageernaa habaynta buuxda ee ku salaysan:

-

waafaqsanaanta cabbirka wafer: 2 ", 4", 6", 8", 12" iyo in ka badan

-

Slot joomatari iyo kala dheeraynta: Waxay dejisaa xajinta cidhifka, taageerada dhinaca dambe, ama naqshadaha waferka ee la xiiray

-

dekedaha nuugaya: godad faakuum ah oo isku dhafan ama kanaalo loogu talagalay maaraynta aan lala xidhiidhin

-

qaabeynta rakibiddaGodad, dunta, godadka ku habboon aaladda dhamaadka robotkaaga

-

Daaweynta dusha sareDhammays sifican, dhabanad leh, ama si fiican loo dhammeeyay (Ra <0.2 µm waa la heli karaa)

-

Ilaalinta cirifka: geeso wareegsan ama shaandheyn si looga fogaado waxyeelada waferka

Isticmaalka sawirada CAD ama moodooyinka 3D ee ay bixiyaan macaamiishu, injineeradayadu waxay wanaajin karaan cudud kasta oo fargeeto ah miisaanka, xoogga, iyo nadaafadda.

Faa'iidooyinka Dhammaystirka dhoobada

| Muuqaal | Faa'iidada |

|---|---|

| Qallafsanaanta Makaanikada Sare | Waxay ilaalisaa saxnaanta cabbirka ee hoos yimaada xoogagga rarka robotiga |

| Waxqabad Heerkuleed heer sare ah | Wuxuu si la isku hallayn karo ugu qabtaa jawi kuleyl sare leh ama balaasmaha |

| Wasakhowga Birta eber | Ma jirto khatar wasakh ah oo ku jirta habaynta semiconductor ee muhiimka ah |

| Dusha Jilicsan ee Hoose | Waxay yaraynaysaa khatarta xoqitaanka ee wafer ama substrate-ka dhalada |

| Anti-static iyo non-magnetic | Ma soo jiidato boodhka mana saameynayso qaybaha xasaasiga ah ee magnetic |

| Nolosha Adeegga Dheer | Xirashada sare ee iska caabinta wareegyada otomaatiga ah ee soo noqnoqda |

| Waafaqid aadka u nadiifsan | Ku habboon ISO 14644 qolalka nadiifka ah (Fasalka 100 iyo wixii ka hooseeya) |

Marka la barbardhigo cududaha caagga ah ama aluminiumka, dhoobada aluminiumku waxay bixisaa degenaansho kiimiko iyo jidheed oo aad u wanagsan oo leh shuruudaha dayactirka ugu yar.

| Hanti | Gacan Bir ah | Cududda Caaga ah | Gacan dhoobada alumina |

|---|---|---|---|

| Adag | Dhexdhexaad | Hoose | Aad u sarreeya (Mohs 9) |

| Deganaanshaha kulaylka | ≤ 500°C | ≤ 150°C | ≥ 1600°C |

| Iska caabinta Kiimikada | Dhexdhexaad | Miskiin | Aad u fiican |

| Ku habboonaanta qolka Nadiifinta | Dhexdhexaad | Hoose | Aad u Sareeya |

| Xiro iska caabin | Dhexdhexaad | Hoose | heer sare ah |

| Xoogga Dielectric | Hoose | Dhexdhexaad | Sare |

| Saxnaanta Mashiinka Gaarka ah | Xaddidan | Dhexdhexaad | Sare (± 0.01mm suurto gal) |

Tilmaamaha Farsamada

| Halbeegga | Qiimaha |

|---|---|

| Qalab | Alumina nadiif ah oo sarreeya (≥ 99.5%) |

| Heerkulka shaqada | Ilaa 1600°C |

| Dusha sare ee Roughness | Ra ≤ 0.2 µm (ikhtiyaar) |

| Cabbirrada Wafer-ka ee Wacan | 2" ilaa 12" ama caado |

| Dulqaadka Dheefta | ± 0.01 mm (ku xiran codsiga) |

| Taageerada Nuugista Vacuum | Ikhtiyaar ah, kanaalada la beddeli karo |

| Xulashada Kordhinta | Bolt-la dhex mara, flange, godad godad ah |

Su'aalaha Inta Badan La Isweydiiyo (FAQ)

Q1: Saamaynlaha dhamaadka ma lagu dhex dari karaa nidaamyada robotic ee jira?

A1:Haa Waxaan taageernaa habaynta ku salaysan is-dhexgalkaaga robotiga. Waxaad noo soo diri kartaa sawir CAD ah ama cabbir flange si sax ah ula qabsiga.

Q2: Gacmaha dhoobada si fudud ma u jabi doonaan marka la isticmaalayo?

A2:Iyadoo dhoobada dabiiciga ah ay jilicsan tahay, naqshadeena waxay isticmaalaan joomatari la hagaajiyay si loo yareeyo feejignaanta walaaca. Marka la eego shuruudaha isticmaalka habboon, waxay bixiyaan nolol adeeg aad uga dheer marka loo eego birta ama caagga.

Q3: Suurtagal ma tahay in tan lagu isticmaalo qolalka faakuumka aadka u sarreeya ama balaasmaha etching qolalka?

A3:Haa dhoobada alumina waa mid aan gaas baxayn, kuleyl ahaan degan, iyo daxalka u adkeysan kara — si fiican ugu haboon faakuum sare, gaaska falceliska, ama bey'ada balasmaha.

Q4: Sidee loo nadiifiyaa ama loo ilaaliyaa qaybahan?

A4:Waxaa lagu nadiifin karaa iyadoo la isticmaalayo biyaha DI, aalkolada, ama saabuunta qolka nadiifka ah. Looma baahna dayactir gaar ah sababtoo ah xasiloonidooda kiimikada iyo dusha sare ee aan firfircoonayn.

Annaga

XKH waxay ku takhasustay horumarinta tignoolajiyada sare, wax soo saarka, iyo iibinta muraayadaha indhaha ee gaarka ah iyo agabka cusub ee crystal. Badeecadahayadu waxay u adeegaan qalabka elektarooniga ah, elektiroonigga macaamiisha, iyo militariga. Waxaan bixinaa qaybaha indhaha ee Sapphire, daboolka muraayadda taleefanka gacanta, Ceramics, LT, Silicon Carbide SIC, Quartz, iyo maraqyada crystal semiconductor. Iyada oo leh khibrad xirfad leh iyo qalab-goynta, waxaan ku fiicanahay habaynta badeecada aan caadiga ahayn, annagoo higsanayna inaan noqono hormuudka agabka optoelectronic shirkad farsamo sare leh.