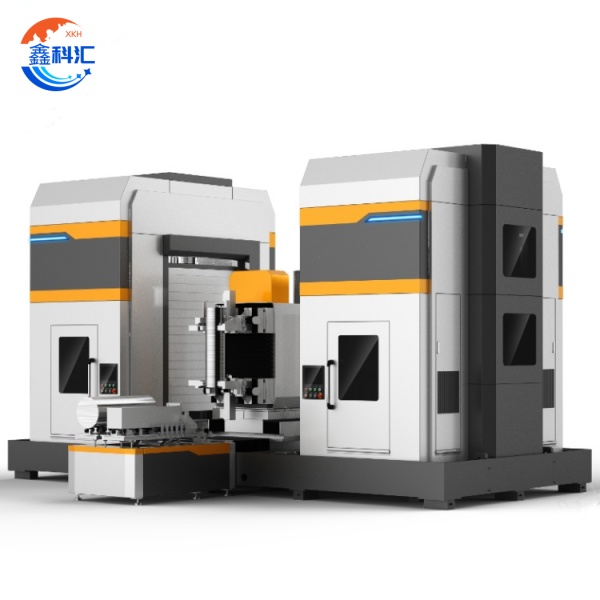

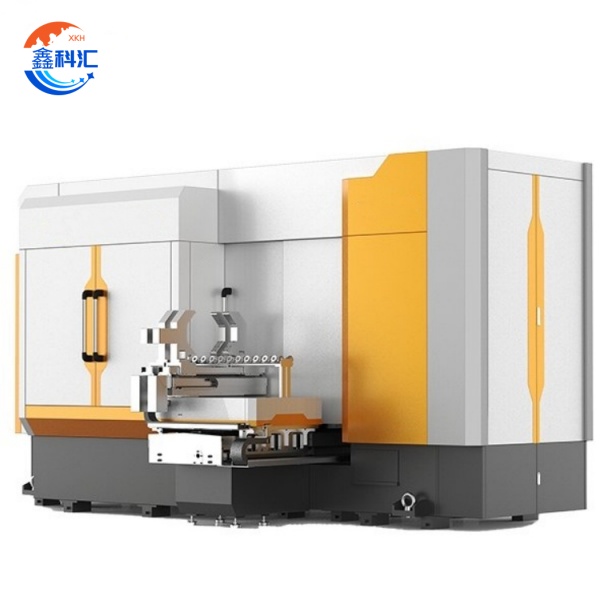

Mashiin laba jibbaaran oo labajibaaran monocrystalline silicon ul farsamaynta 6/8/12 inch flatness oogada Ra≤0.5μm

Tilmaamaha qalabka:

(1) Habayn isku mid ah oo laba-geesood ah

Waxtarka labanlaab: Habaynta isku mar ee laba ulood oo silikoon ah (Ø6"-12") waxay kordhisaa wax soo saarka 40% -60% vs. Qalabka Simplex.

Xakamaynta madax-bannaan: Saldhig kastaa wuxuu si madax-bannaan u hagaajin karaa cabbirrada goynta (xeerka, xawaaraha quudinta) si uu ula qabsado qaababka kala duwan ee usha silikoon.

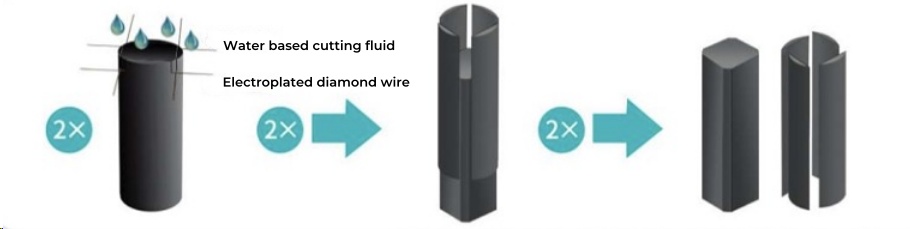

(2) Goynta sare ee saxda ah

Saxnaanta cabbirka: dulqaadka masaafada dhinaca bar labajibbaaran ± 0.15mm, kala duwan ≤0.20mm.

Tayada dusha sare: goynta cidhifyada <0.5mm, yarayso xadiga shiidada xigta.

(3) Xakamaynta caqliga

Goynta la qabsiga: la socodka wakhtiga dhabta ah ee qaab-dhismeedka usha silikon, hagaajinta firfircoon ee dariiqa goynta (sida farsamaynta usha silikoon qaloocan).

· Raadinta xogta: diiwaan geli cabbirrada habaynta ee usha silikoon kasta si ay u taageerto xidhitaanka nidaamka MES.

(4) Kharash yar oo la isticmaali karo

Isticmaalka siliga dheeman: ≤0.06m/mm (dhererka usha silikoonka), dhexroorka siliga ≤0.30mm.

Wareegga qaboojiyaha: Nidaamka sifaynta wuxuu kordhiyaa nolosha adeegga wuxuuna yareeyaa daadinta dareeraha qashinka.

Farsamada iyo faa'iidooyinka horumarka:

(1) Goynta tignoolajiyada hagaajinta

- Goynta khadadka badan: 100-200 xariiqyo dheeman ah ayaa loo isticmaalaa isbarbardhigga, iyo xawaaraha goynta waa ≥40mm / min.

- Xakamaynta xiisadda: Nidaamka hagaajinta wareegga xiran (± 1N) si loo yareeyo khatarta jabinta siliga.

(2) Kordhinta waafaqid

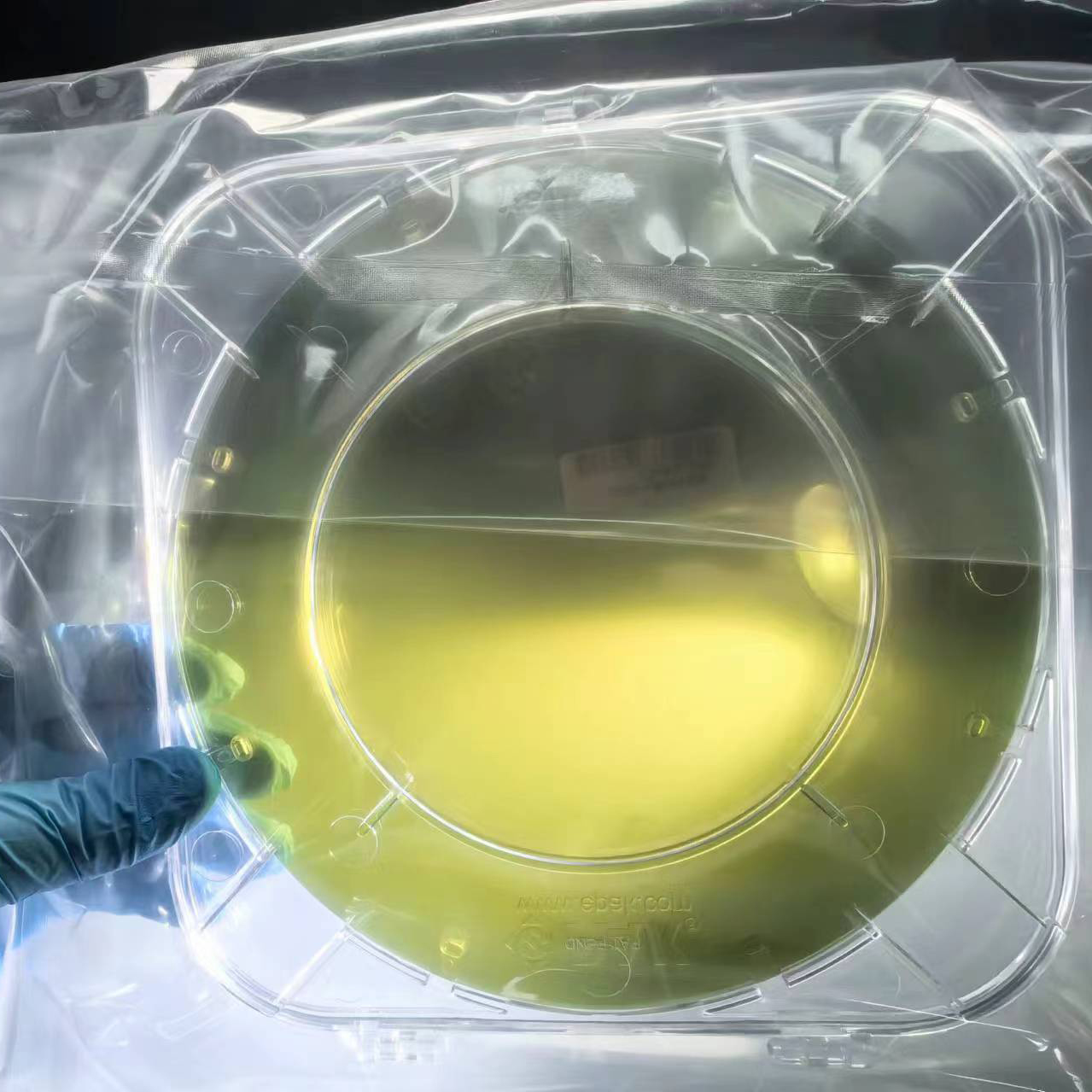

La qabsiga agabka: Taageerada nooca P-nooca monocrystalline silikoon, oo la jaan qaadaya TOPCon, HJT iyo ulo kale oo silikoon batari tayo sare leh.

- Cabbirka dabacsan: dhererka usha silikoon 100-950mm, masaafada dhinac ul labajibbaaran 166-233mm la hagaajin karo.

(3) Kor u qaadida otomaatiga

- Rarista iyo dejinta Robot: si toos ah u rarista/dejinta ulaha silikoon, garaac ≤3 daqiiqo.

- Baadhista caqliga leh: Dayactirka saadaalinta si loo yareeyo wakhtiga dhimista ee aan la qorshayn.

(4) Hoggaanka warshadaha

- Taageerada wafer: waxay farsamayn kartaa ≥100μm silikon khafiif ah oo khafiif ah oo leh ulo labajibbaaran, heerka jajabinta <0.5%.

- Kordhinta isticmaalka tamarta: Isticmaalka tamarta unug kasta oo usha silikoon ah ayaa la dhimay 30% (marka loo eego qalabka dhaqanka).

Qiyaasaha farsamada:

| Magaca halbeegga | Qiimaha index |

| Tirada baararka la habeeyey | 2 xabbo / dhig |

| Kala duwanaanshaha dhererka baararka farsamaynta | 100 ~ 950mm |

| Kala duwanaanshaha margin machining | 166 ~ 233mm |

| Xawaaraha jarista | ≥40mm/daqiiqo |

| Xawaaraha siliga dheeman | 0 ~ 35m/s |

| Dhexroor dheeman | 0.30 mm ama ka yar |

| Isticmaalka tooska ah | 0.06 m/mm ama ka yar |

| Dhexroor usha wareega ee ku habboon | Dhammaystirka dhexroorka usha labajibbaaran ee +2mm, Hubi heerka ka gudubka dhalaalka |

| Xakamaynta jebinta cidhifyada | Cidhifka ceeriin ≤0.5mm, Ma jajabin, tayada dusha sare |

| lebbiska dhererka Arc | Qiyaasta qiyaasta <1.5mm, Marka laga reebo qalloocinta usha silikoon |

| Cabirka mashiinka (mashiinka keliya) | 4800×3020×3660mm |

| Wadarta awooda la qiimeeyay | 56kW |

| Miisaanka qalabka dhintay | 12t |

Shaxda saxda ah ee mashiinka:

| Shayga saxda ah | Kala duwanaanshaha dulqaadka |

| Dulqaadka bar labajibbaaran | ±0.15mm |

| kala duwanaanshaha cidhifyada bar labajibbaaran | ≤0.20mm |

| Xagasha dhammaan dhinacyada usha labajibbaaran | 90°±0.05° |

| Flat of usha square | ≤0.15mm |

| Robot ku celceliyay saxnaanta meelaynta | ±0.05mm |

Adeegyada XKH:

XKH waxay bixisaa adeegyo wareeg ah oo buuxa oo loogu talagalay mashiinnada laba-geesoodka ah ee mono-crystalline silicon, oo ay ku jiraan hagaajinta qalabka (ku habboon ulaha silikoon ee waaweyn), habka komishanka (goynta hagaajinta cabbirka), tababarka hawlgalka iyo taageerada iibka ka dib (qaybaha muhiimka ah, ogaanshaha fogaanta), hubinta in macaamiishu ay helaan wax-soo-saar sare (> 99%) iyo wax-soo-saarka qiimaha hooseeya, iyo bixinta hagaajinta farsamada (sida AI). Muddada dhalmada waa 2-4 bilood.

Jaantus faahfaahsan