Mashiinka Goynta Siliga Saddex-goob ah ee Dheeman-ka ah ee Goynta Wafer/Muraayada indhaha ah

Hordhac Product

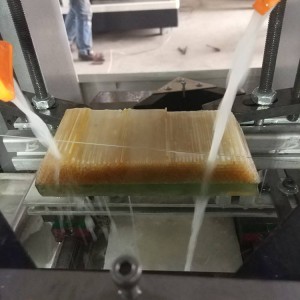

Siliga dheemanka ah ee saddex-goob ah mishiinka goynta hal-xadhiggu waa qalab-goyn heer sare ah oo tayo sare leh oo loogu talagalay qalabka adag iyo kuwa jilicsan. Waxay u isticmaashaa siligga dheemanka ah dhexdhexaadinta waxayna ku habboon tahay habaynta saxda ah ee alaabta adag sida wafers silicon, sapphire, silicon carbide (SiC), ceramics, iyo muraayadaha indhaha. Muujinta naqshadeynta saddex-goobo, mashiinkani wuxuu awood u siinayaa isku mar goynta qaybo badan oo shaqo oo hal qalab ah, si weyn u wanaajinaya waxtarka wax soo saarka iyo dhimista kharashka wax soo saarka.

Mabda'a Shaqada

- Goynta Xadhkaha Dheeman: Wuxuu adeegsadaa silig dheeman ah oo korantada ku xidhan ama resin-ku-xidhan si uu u sameeyo goyn ku salaysan wax shiidi iyadoo loo marayo dhaq-dhaqaaq iscelin xawaare sare leh.

- Goynta Isku-dhafka Saddex-Station: Waxaa lagu qalabeeyay saddex goob shaqo oo madax-bannaan, taasoo u oggolaanaysa in isla mar la gooyo saddex qaybood si kor loogu qaado wax-soo-saarka.

- Xakamaynta xiisadda: Wuxuu ku daraa nidaamka xakamaynta xiisadda saxda ah ee saxda ah si loo ilaaliyo xiisadda siliga dheemanka ee deggan inta lagu jiro jarista, hubinta saxnaanta.

- Nidaamka Qaboojinta & Saliidaynta: Waxay shaqaalaysaa biyo fuuqsan ama qaboojiye khaas ah si loo yareeyo burburka kulaylka oo uu u kordhiyo cimriga siliga dheemanka.

Tilmaamaha Qalabka

- Goynta Saxnaanta Sare: Waxay ku guulaysataa goynta saxnaanta ± 0.02mm, oo ku habboon farsamaynta waferka aadka u khafiifka ah (tusaale, maraqa silikoon sawir-qaade ah, waferrada semiconductor).

- Waxtarka sare: Naqshadaynta saddexda saldhig waxay kordhisaa wax soo saarka in ka badan 200% marka la barbar dhigo mashiinnada hal-meeloodka ah.

- Khasaaraha Walxaha Hoose: Naqshadaynta kerf cidhiidhi ah (0.1-0.2mm) waxay yaraynaysaa qashinka alaabta.

- Automation Sare: Waxa uu leeyahay si toos ah u rarista, toosinta, goynta, iyo habaynta dejinta, iyada oo yaraynaysa faragelinta gacanta.

- Laqabsiga Sare: Awood u leh inuu gooyo walxo adag oo jajaban oo kala duwan, oo ay ku jiraan silikoon monocrystalline, silicon polycrystalline, sapphire, SiC, iyo ceramics.

Faa'iidooyinka Farsamada

| Faa'iidada

| Sharaxaada

|

| Goynta Isku-dhafka Saldhigga Badan

| Saddex saldhig oo si madaxbanaan loo maamulo ayaa awood u siinaya in la gooyo qaybo ka mid ah dhumucdooda ama alaabooyin kala duwan, hagaajinta isticmaalka qalabka.

|

| Xakamaynta kacsanaanta caqliga

| Xakamaynta wareegga xiran ee matoorada servo iyo dareemayaasha waxay hubisaa xiisadda siliga joogtada ah, ka hortagga jebinta ama goynta leexashada.

|

| Qaab-dhismeedka Adag-sare

| Tilmaamaha toosan ee saxda ah ee saxda ah iyo nidaamyada servo-driven waxay xaqiijiyaan goynta xasilloon waxayna yareeyaan saameynta gariirka.

|

| Waxtarka Tamarta & Saaxiibtinimada Deegaanka

| Marka la barbar dhigo goynta slurry-dhaqameedka, goynta siliga dheemanka ah waa mid wasakh la'aan ah, iyo qaboojiye dib ayaa loo warshadayn karaa, taas oo yaraynaysa kharashka daaweynta qashinka.

|

| Kormeerka Caqliga leh

| Ku qalabaysan PLC iyo nidaamyada xakamaynta shaashadda taabashada ee la socodka waqtiga-dhabta ah ee goynta xawaaraha, xiisadda, heerkulka, iyo cabbirrada kale, taageeraya raadinta xogta. |

Tilmaamaha Farsamada

| Qaabka | Saddex saldhig dheeman hal xariiq mashiinka goynta |

| Cabbirka shaqada ugu badan | 600*600mm |

| Xawaaraha orodka fiilada | 1000 (MIX) m/daqiiqo |

| Dhexroorka siliga dheeman | 0.25-0.48mm |

| Awoodda kaydinta khadka ee giraangiraha sahayda | 20km |

| Kala goynta dhumucda | 0-600mm |

| Saxnimada goynta | 0.01mm |

| Kor u qaadida toosan ee goobta shaqada | 800mm |

| Habka goynta | Maaddadu waa mid taagan, oo siligga dheemanka ah ayaa lulaya oo soo degaya |

| Goynta xawaaraha quudinta | 0.01-10mm/min (Marka loo eego walxaha iyo dhumucda) |

| Haanta biyaha | 150L |

| Dheecaan goynta | Dareeraha goynta waxtarka sare ee miridhku |

| xagal lulid | ±10° |

| Xawaaraha lulida | 25°/s |

| Xiisad goynta ugu badan | 88.0N (Deji cutubka ugu yar0.1n) |

| Goynta qoto dheer | 200-600mm |

| Samee taargooyin isku xira oo u dhigma iyadoo loo eegayo kala goynta macaamilka | - |

| Goobta shaqada | 3 |

| Korontada | Saddex waji shan silig AC380V/50Hz |

| Wadarta awooda qalabka mashiinka | ≤32kw |

| Matoorka ugu muhiimsan | 1*2kw |

| Matoorka fiilada | 1*2kw |

| Matoorka lulida ee goobta shaqada | 0.4*6kw |

| Matoorka xakamaynta kacsanaanta | 4.4*2kw |

| Siidaynta iyo matoorka ururinta | 5.5*2kw |

| Cabirka dibadda (marka laga reebo sanduuqa cududda dhagaxa) | 4859*2190*2184mm |

| Cabirka dibadda (ay ku jiraan sanduuqa cududda dhagaxa) | 4859*2190*2184mm |

| Miisaanka mashiinka | 3600ka |

Goobaha Codsiga

- Warshadaha sawir-qaadista: Goynta monocrystalline iyo silikoon polycrystalline ingots si loo hagaajiyo dhalidda waferka.

- Warshadaha Semiconductor: Goynta saxda ah ee SiC iyo waferrada GaN.

- Warshadaha LED: Goynta sapphire substrates ee soo saarista chip LED.

- Ceramics Advanced: Samaynta iyo jarida dhoobada waxqabadka sare sida alumina iyo silicon nitride.

- Muraayadaha indhaha: Habka saxda ah ee muraayadda aadka u dhuuban ee muraayadaha kamaradaha iyo daaqadaha infrared.