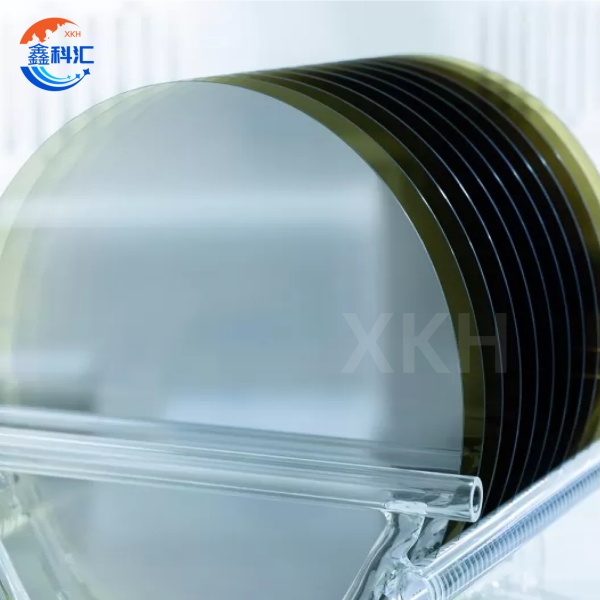

Substrates SiC Seed Crystal Dia 205/203/208 Nooca 4H-N ee Isgaarsiinta indhaha

Xuduudaha farsamada

Silikon carbide wafer | |

Noocyo badan | 4H |

Khaladka jihaynta dusha sare | 4° dhanka <11-20>±0.5º |

iska caabin | habaynta |

Dhexroorka | 205 ± 0.5mm |

Dhumucda | 600± 50μm |

Qalafsanaan | CMP, Ra≤0.2nm |

Cufnaanta Dheef-yar | ≤1 ea/cm2 |

xoqid | ≤5, Wadarta Dhererka≤2* Dhexroor |

Chips-ka-geeska/indents | Midna |

Calaamadaynta laysarka hore | Midna |

xoqid | ≤2, Wadarta Dhererka≤ Dhexroorka |

Chips-ka-geeska/indents | Midna |

Aagagga nooca badan | Midna |

Calaamadaynta laser-ka dambe | 1mm (laga bilaabo cidhifka sare) |

Cidhif | Chamfer |

Baakadaha | Cajalad badan oo wafer ah |

Astaamaha Muhiimka ah

1. Dhismaha Crystal iyo Waxqabadka Korontada

Xasiloonida Crystallographic: 100% 4H-SiC xukunka nooca badan, eber ka mid ahaanshaha multicrystalline (tusaale, 6H/15R), oo leh XRD ruxitaanka qalooca oo dhan ballac badhkii (FWHM) ≤32.7 arcsec.

Dhaqdhaqaaqa Qaade Sare: Dhaqdhaqaaqa korantada ee 5,400 cm²/V·s (4H-SiC) iyo socodka dalool ee 380 cm²/V·s, taas oo awood u siinaysa naqshadaynta aaladaha soo noqnoqda.

Qallafsanaanta Shucaaca: Waxay u adkaysataa 1 MeV neutron irradiation oo leh heerka dhaawaca barokaca ee 1 × 10¹⁵ n/cm², ku habboon hawada hawada iyo codsiyada nukliyeerka.

2. Guryaha kulaylka iyo Makaanikada

Habdhaqanka kulaylka ee aan caadiga ahayn: 4.9 W/cm · K (4H-SiC), saddex jibaarma silikoon, hawlgalka taageeraya ee ka sarreeya 200°C.

Iskuxidhka Balaadhinta kulaylka Hoose: CTE ee 4.0×10⁻⁶/K (25–1000°C), hubinta in ay waafaqsan yihiin baakadaha silikoon-ku-salaysan iyo yaraynta diiqada kulaylka.

3. Xakamaynta iyo habaynta saxnaanta

Cufnaanta tuubbooyinka yar yar: <0.3 cm⁻² (8-inch wafers), cufnaanta kala-baxa <1,000 cm⁻² (lagu xaqiijiyay KOH etching).

Tayada dusha sare: CMP-oo la safeeyey ilaa Ra <0.2 nm, oo buuxinaysa shuruudaha siman ee darajada lithography ee EUV.

Codsiyada Muhiimka ah

| Domain | Dhacdooyinka Codsiga | Faa'iidooyinka Farsamada |

| Isgaarsiinta indhaha | 100G/400G leysarka, Silicon photonics modules hybrid | Substrates abuurka InP waxay awood u siinaysaa bandheynta tooska ah (1.34 eV) iyo heteroepitaxy-ku-salaysan, taasoo yaraynaysa khasaaraha isku xidhka indhaha. |

| Baabuurta Tamarta Cusub | 800V rogayaasha korantada sare leh, dabaysha dusha saaran (OBC) | 4H-SiC substrates waxay u adkeysanayaan> 1,200 V, hoos u dhigista khasaaraha socodka 50% iyo mugga nidaamka 40%. |

| Isgaarsiinta 5G | Aaladaha RF millimeter-mowjadaha (PA/LNA), cod-weyneyaasha saldhigga saldhigga | Substrates-ka-soo-jiidashada SiC (iska-caabbinta>10⁵ Ω·cm) waxay awood u siinaysaa soo noqnoqoshada sare (60 GHz+) is-dhexgalka dadban. |

| Qalabka Warshadaha | Dareemayaal heerkul sare leh, Transformers hadda, kormeerayaasha reactor nuclear | Substrates abuurka InSb (0.17 eV bandgap) waxay keenaan dareenka magnetka ilaa 300%@10 T. |

Faa'iidooyinka Muhiimka ah

SiC (silicon carbide) substrates abuurka abuurku waxay bixiyaan waxqabad aan la mid ahayn oo leh 4.9 W / cm · K kuleylka kuleylka, 2-4 MV / cm burburka xoogga beerta, iyo 3.2 eV bandgap ballaaran, awood sare leh, soo noqnoqoshada sare, iyo codsiyada heerkulka sare. Muujinaya cufnaanta micropipe eber iyo <1,000 cm⁻² cufnaanta kala-baxa, substrate-yadani waxay xaqiijinayaan isku halaynta xaaladaha daran. Jidh la'aantooda kiimikaad iyo sagxadaha CVD-ku-xiran (Ra <0.2 nm) waxay taageeraan korriinka heteroepitaxial horumarsan (tusaale, SiC-on-Si) ee optoelectronics iyo nidaamyada korantada EV.

Adeegyada XKH:

1. Wax-soo-saarka gaarka ah

Foomamka Waferka Dabacsan: 2–12-inji maraqa oo googooyo wareeg ah, leydi ah, ama qaab gaar ah u samaysan (±0.01 mm dulqaad).

Xakamaynta doping: Nayroojiin sax ah (N) iyo aluminium (Al) doping oo la sii marinayo CVD, gaarista iska caabintu waxay u dhaxaysaa 10⁻³ ilaa 10⁶ Ω·cm.

2. Tiknoolajiyada Geedi socodka Horukacsan;

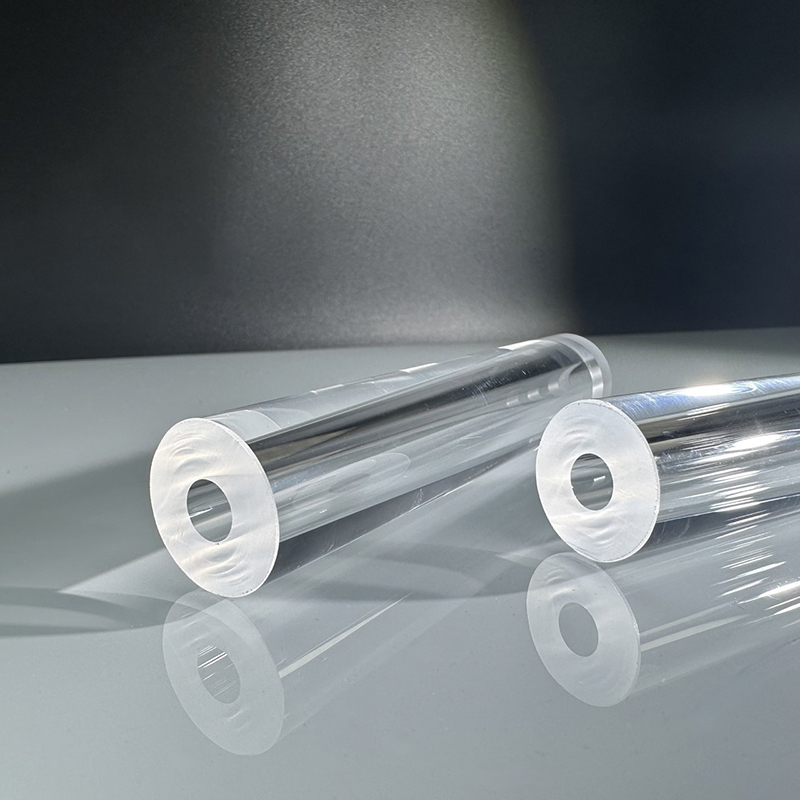

Heteroepitaxy: SiC-on-Si (ku habboon 8-inji khadadka silikon) iyo SiC-on-Diamond (kuleylka kuleylka> 2,000 W/m·K).

Yaraynta cilladda: Etching Hydrogen-ka iyo soo-jiidashada si loo yareeyo cilladaha micropipe/cufnaanta, hagaajinta wax-soo-saarka wafer ilaa> 95%.

3. Nidaamyada Maareynta Tayada;

Tijaabada dhamaadka-ilaa-dhamaadka: Raman spectroscopy (xaqiijinta polytype), XRD (crystallinity), iyo SEM (falanqaynta cilladda).

Shahaadooyinka: U hoggaansan AEC-Q101 (baabuur), JEDEC (JEDEC-033), iyo MIL-PRF-38534 ( darajo-militari).

4. Taageerada Silsilada Supply Global;

Awoodda Wax-soo-saarka: Wax-soo-saarka bishii> 10,000 wafers (60% 8-inch), oo leh 48-saac oo degdeg ah.

Shabakadda Saadka: Daboolista Yurub, Waqooyiga Ameerika, iyo Aasiya-Pacific iyada oo loo marayo xamuulka hawada/badeedka oo leh baakado heerkulku kantaroolo.

5. Horumarinta Farsamada;

Shaybaadhada R&D ee Wadajirka ah: Ka wada-shaqeyn tayaynta baakadaha awoodda SiC moduleka (tusaale, isdhexgalka substrate DBC).

Shatiga IP: Bixi GaN-on-SiC RF shatiga kobaca tignoolajiyada epitaxial si loo yareeyo kharashaadka R&D macmiilka.

Soo koobid

SiC (silikon carbide) substrates crystal abuurka, sida walxo istiraatijiyadeed, waxay dib u qaabaynaysaa silsiladaha warshadaha caalamiga ah iyada oo loo marayo horumarada koritaanka crystal, xakamaynta cilladda, iyo isdhexgalka kala duwan. Iyada oo si joogto ah loo horumarinayo dhimista cilladaha wafer-ka, cabirka wax-soo-saarka 8-inch, iyo ballaarinta aaladaha heteroepitaxial (tusaale, SiC-on-Diamond), XKH waxay soo bandhigtaa isku halleyn sare, xalal wax ku ool ah oo loogu talagalay optoelectronics, tamar cusub, iyo wax soo saar horumarsan. Ballanqaadkayaga hal-abuurnimadu waxay hubisaa in macaamiishu horseed u noqdaan dhexdhexaadnimada kaarboon iyo nidaamyada garaadka, wadista xilliga soo socda ee nidaamyada deegaanka semiconductor-ballaaran.