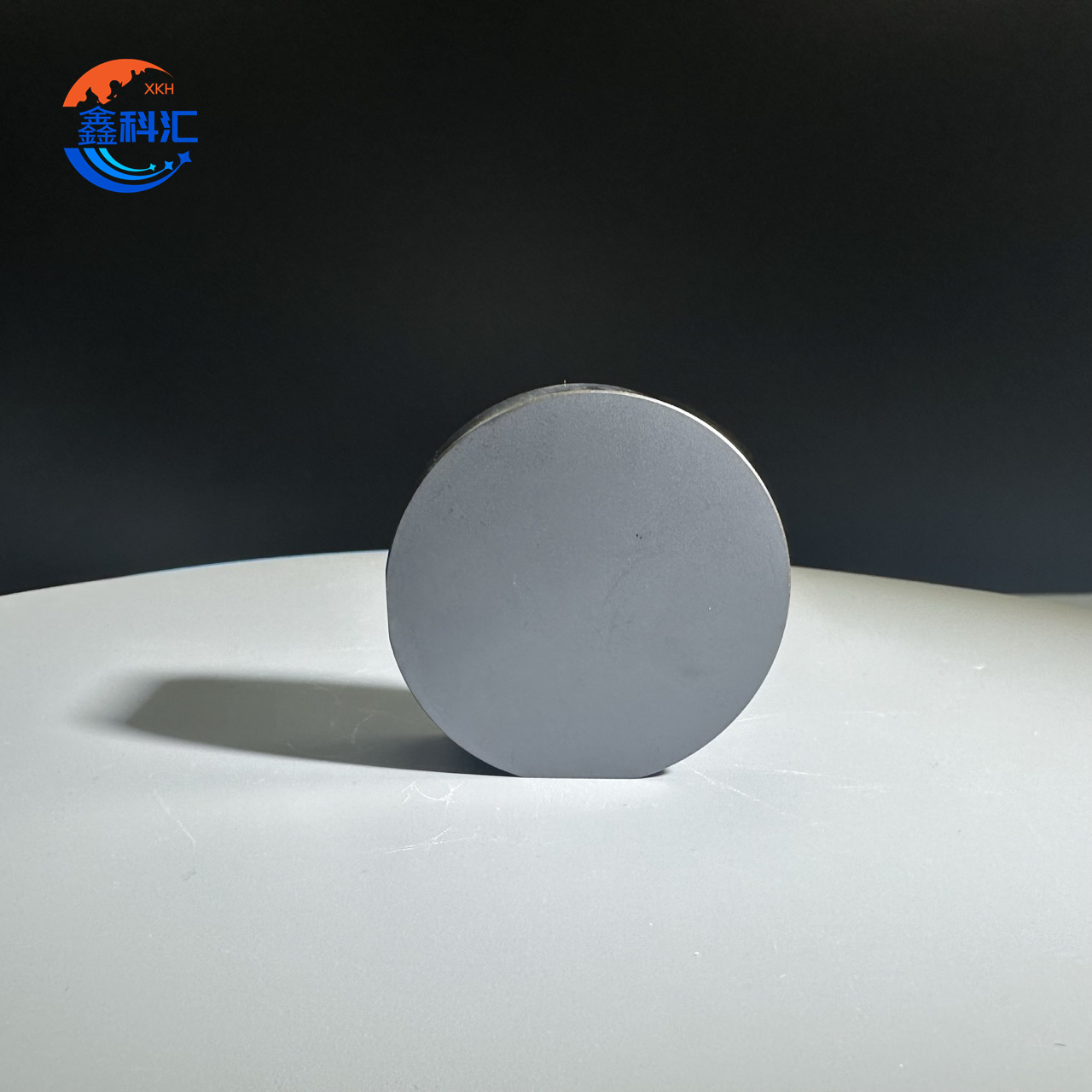

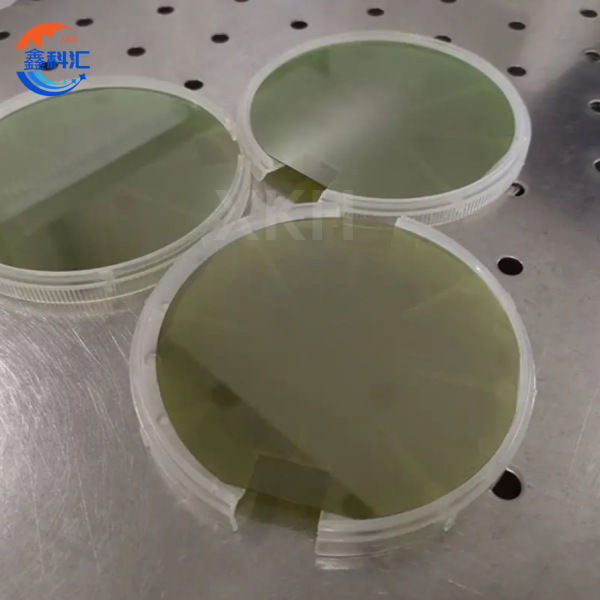

Custom N Nooca SiC Seed Substrate Dia153/155mm ee Korontada Elektarooniga ah

Soo bandhig

Silicon Carbide (SiC) Substrate-yada abuurku waxay u adeegaan sida walxaha aasaasiga ah ee jiilka saddexaad ee semiconductors, oo ay ku kala soocaan kuleylkooda kuleylkooda aadka u sarreeya, xoogga goobta korantada ee burbursan, iyo dhaqdhaqaaqa elektaroonigga sare. Guryahaan ayaa ka dhigaya kuwo aan looga maarmin korantada elektiroonigga ah, aaladaha RF, baabuurta korontada (EVs), iyo codsiyada tamarta la cusboonaysiin karo. XKH waxay ku takhasustay R&D iyo soosaarka substrates abuurka tayada sare leh ee SiC, adoo adeegsanaya farsamooyinka korriinka korriinka ee horumarsan sida Gaadiidka Jirka Uumiga (PVT) iyo Dhigista Uumiga Kiimikada Heerkulka Sare (HTCVD) si loo hubiyo tayada kristanta ee hogaamineysa warshadaha.

XKH waxay bixisaa 4-inji, 6-inch, iyo 8-inch substrates SiC abuur leh oo leh nooca N-nooca/P-doping, gaaritaanka heerarka iska caabbinta ee 0.01-0.1 Ω·cm iyo cufnaanta kala-baxa ee ka hooseeya 500 cm⁻², taas oo ka dhigaysa mid ku habboon soo saarista MOSFETs, Schottky Barrier Diodes. Nidaamkeena wax-soo-saarka tooska ah ee isku-dhafan wuxuu daboolayaa korriinka korriinka, goynta wafer-ka, dhalaalka, iyo kormeerka, oo leh awood wax-soo-saar bille ah oo ka badan 5,000 wafers si loo daboolo baahiyaha kala duwan ee machadyada cilmi-baarista, soo-saareyaasha semiconductor, iyo shirkadaha tamarta la cusboonaysiin karo.

Intaa waxaa dheer, waxaan bixinaa xalal gaar ah, oo ay ku jiraan:

Habaynta hanuuninta Crystal (4H-SiC, 6H-SiC)

Doping khaas ah (Aluminium, Nitrogen, Boron, iwm.)

Naaxinta aadka u jilicsan (Ra <0.5 nm)

XKH waxay taageertaa muunad ku salaysan habayn, la tashiyo farsamo, iyo qaabaynta dufcad yar si loo bixiyo xalalka substrate-ka ee la wanaajiyay.

Xuduudaha farsamada

| Silikon carbide wafer | |

| Noocyo badan | 4H |

| Khaladka jihaynta dusha sare | 4° dhanka <11-20>±0.5º |

| iska caabin | habaynta |

| Dhexroorka | 205 ± 0.5mm |

| Dhumucda | 600± 50μm |

| Qalafsanaan | CMP, Ra≤0.2nm |

| Cufnaanta Dheef-yar | ≤1 ea/cm2 |

| xoqid | ≤5, Wadarta Dhererka≤2* Dhexroor |

| Chips-ka-geeska/indents | Midna |

| Calaamadaynta laysarka hore | Midna |

| xoqid | ≤2, Wadarta Dhererka≤ Dhexroorka |

| Chips-ka-geeska/indents | Midna |

| Aagagga nooca badan | Midna |

| Calaamadaynta laser-ka dambe | 1mm (laga bilaabo cidhifka sare) |

| Cidhif | Chamfer |

| Baakadaha | Cajalad badan oo wafer ah |

Substrates Abuurka SiC - Tilmaamaha Muhiimka ah

1. Qalabka Jirka ee Gaarka ah

Heerarka kulaylka sare (~ 490 W/m·K), oo si aad ah uga sarreeya silicon (Si) iyo gallium arsenide (GaAs), taasoo ka dhigaysa mid ku habboon qaboojinta cufnaanta sare ee qalabka.

Xoogagga goobta oo burburay (~ 3 MV/cm), awood u siinaya hawlgal xasiloon oo ku hoos jira xaaladaha korantada sare, oo muhiim u ah rogoyaasha EV iyo qaybaha tamarta warshadaha.

· Xajmiga ballaaran (3.2 eV), yaraynta qulqulka qulqulka ee heerkulka sare iyo kor u qaadida isku halaynta aaladda.

2. Tayada Crystalline Sare

Tignoolajiyada kobaca isku-dhafka ah ee PVT + HTCVD waxay yaraynaysaa cilladaha yaryar, iyadoo ilaalinaysa cufnaanta kala-baxa ee ka hooseeya 500 cm⁻².

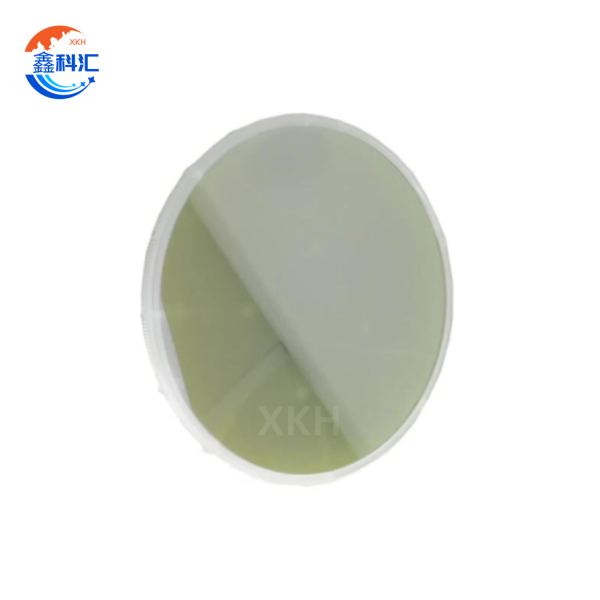

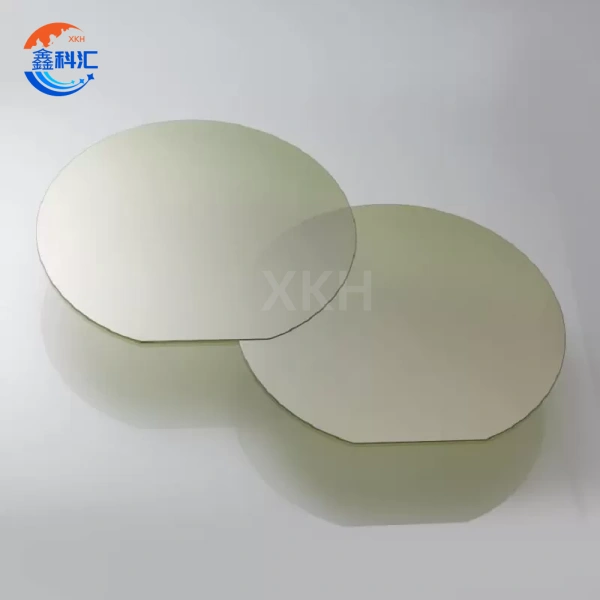

Qaansada wafer/warp <10 μm iyo qallafsanaanta dusha sare Ra <0.5 nm, iyada oo hubinaysa waafaqid lithography-ga saxda ah ee saxda ah iyo hababka meel dhigista filimada khafiifka ah.

3. Ikhtiyaarada Doping ee kala duwan

·N-nooca (Nitrogen-doped): iska caabin hoose (0.01-0.02 Ω·cm), loogu hagaajiyay aaladaha RF-soo noqnoqda ee sarreeya.

Nooca P (Aluminum-doped): Ku habboon MOSFETs awoodda iyo IGBTs, hagaajinta dhaqdhaqaaqa sideyaasha.

SiC-dahaarka-hoosaadka ah (Vanadium-doped): Resistivity> 10⁵ Ω·cm, oo loogu talagalay 5G RF cutubyada-dhamaadka hore.

4. Deganaanshiyaha Deegaanka

Iska caabin heerkul sare ah (>1600°C) iyo adkaanta shucaaca, oo ku haboon hawada hawada, qalabka nukliyeerka, iyo bay'ada kale ee xad dhaafka ah.

Substrates Abuurka SiC - Codsiyada aasaasiga ah

1. Korontada Elektarooniga ah

Gawaadhida Korontada (EVs): Waxaa loo isticmaalaa xajiyeyaasha-korka (OBC) iyo rogayaasha si loo hagaajiyo hufnaanta loona yareeyo baahida maamulka kulaylka.

Nidaamyada Awoodda Warshadaha: Waxay xoojisaa rogo-rogayaasha sawir-qaadista iyo xadhkaha xariifka ah, iyagoo gaadhay> 99% hufnaanta beddelka awoodda.

2. Qalabka RF

Saldhigyada Saldhigga 5G: Substrate-yada SiC-da-daahiyaha ah waxay awood u siinayaan GaN-on-SiC RF koronto-weyneyayaasha, taageeraya soo noqnoqoshada sare, gudbinta calaamadaha awoodda sare.

Isgaarsiinta Satellite-ka: Tilmaamaha khasaaraha hooseeya ayaa ka dhigaya mid ku habboon aaladaha hirarka millimitirka ah.

3. Kaydinta Tamarta & Tamarta la cusboonaysiin karo

Korontada Qoraxda: SiC MOSFETs waxay kor u qaadaysaa wax ku oolnimada beddelka DC-AC iyada oo la dhimayo kharashyada nidaamka.

Nidaamyada Kaydinta Tamarta (ESS): Waxay wanaajisaa beddelayaasha laba jiho waxayna kordhisaa cimriga batteriga.

4. Difaaca & Hawada

Nidaamyada Raadaarka: Aaladaha SiC ee awoodda sare leh waxaa lagu isticmaalaa AESA (Active Electronically Scanned Array).

· Maareynta Awoodda Dayax-gacmeedka: Substrate-yada SiC-da u adkaysta shucaaca ayaa muhiim u ah hawlgallada meel-dheer.

5. Cilmi-baarista & Teknolojiyadda Soo Koraysa

Xisaabinta Quantum: SiC-nadiifinta sare waxay awood u siisaa cilmi-baarista qubit-ka.

Dareemayaasha Heerkulka Sare: Waxaa la geeyay sahaminta saliidda iyo la socodka tamarta nukliyeerka.

Substrates Abuurka SiC - Adeegyada XKH

1. Faa'iidooyinka Silsiladda Supply

· Wax soo saar toos ah oo isku dhafan: Xakameyn buuxda laga bilaabo budada SiC ee nadiifka ah ilaa waferrada la dhammeeyey, hubinta waqtiyada rasaasta ee 4-6 toddobaad ee alaabta caadiga ah.

Qiimaha tartanka: Dhaqaalaha miisaanku waxa uu sahlayaa 15-20% qiime ka hooseeya kan tartamayaasha, iyadoo la taageerayo Heshiisyada Muddada Dheer (LTAs).

2. Adeegyada Habaynta

Hanuuninta Crystal: 4H-SiC (standard) ama 6H-SiC (codsiyada gaarka ah).

Kordhinta doping: Habaysan N-nooca/P-nooca/ guryaha dahaarka badheed.

Naaxinta sareeysa: polishing CMP iyo daawaynta dusha u diyaarsan (Ra <0.3 nm).

3. Taageerada Farsamada

Tijaabada muunada bilaashka ah: Waxaa ku jira XRD, AFM, iyo warbixinnada cabbiraadda saamaynta Hoolka.

Caawinta jilitaanka aaladda: Waxay taageertaa korriinka epitaxial iyo hagaajinta naqshadaynta aaladda.

4. Jawaab degdeg ah

Samaynta mugga hoose: Dalabka ugu hooseeya ee 10 wafer, oo la keeno 3 toddobaad gudahood.

· Saadka caalamiga ah: Iskaashatada DHL iyo FedEx ee gaarsiinta guri-ilaa-albaab.

5. Xaqiijinta tayada

Kormeerka hab-socod-buuxa ah: Wuxuu daboolaa sawir-gacmeedka raajada (XRT) iyo falanqaynta cufnaanta cilladaysan.

Shahaadooyinka caalamiga ah: Waafaqsan IATF 16949 (heerarka baabuurta) iyo AEC-Q101.

Gabagabo

Abuurka abuurka SiC ee XKH wuxuu aad ugu sarreeyaa tayada crystalline, xasilloonida silsiladda sahayda, iyo dabacsanaanta habeynta, u adeegida korontada, isgaarsiinta 5G, tamarta la cusboonaysiin karo, iyo tignoolajiyada difaaca. Waxaan sii wadeynaa hormarinta 8-inch ee tignoolajiyada wax soo saarka ballaaran ee SiC si aan horay ugu wadno warshadaha jiilka saddexaad.