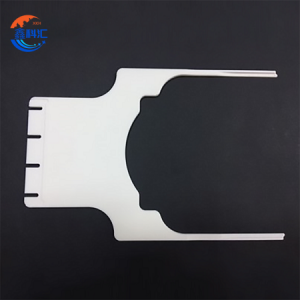

Alumina Ceramic End Effector / Gacan Fargeeto ah oo loogu talagalay Wafer iyo Qabashada Substrate

Jaantus faahfaahsan

Dulmarka Alumina Ceramic End Effector

Alumina Ceramic End Effector, oo sida badan loogu yeero gacanta fargeeto dhoobada ah ama xejinta dhoobada, waa aalad muhiim ah oo loo isticmaalo automation-ka robotiga iyo khadadka wax soo saarka qolka nadiifka ah. Alumina Ceramic End Effector waxaa lagu rakibay cudud robotic ah oo ah isdhexgalka ugu dambeeya ee badeecada, mas'uul ka ah soo qaadista, qabashada, toosinta, iyo wareejinta qaybaha aadka xasaasi u ah sida weelka silikoon, muraayadaha dhalada, ama qaybaha microelectronic.

Waxaa laga soo saaray dhoobada alumina ultra-pure (Al2O3), cududdan fargeetada ah waxay siisaa xal si gaar ah nadiif ah oo xasiloon jawiyada aan loo dulqaadan karin wasakhowga birta, qallafsanaanta caaga ah, ama jiilka walxaha.

Qalabka Alaabta - Waa maxay sababta Alumina

Ku saabsan Alumina Ceramic End Effector, Alumina (Al2O3) waa mid ka mid ah kuwa ugu caansan oo la isku halleyn karodhoobada injineernimada sare. Darajada aan isticmaalno (≥99.5% daahirnimo) waxay bixisaa isku darka gaarka ah ee tayada jireed iyo kiimikaad taas oo ka dhigaysa walxaha doorashada semiconductor iyo codsiyada faakuumka:

-

Adag aad u daran- Iyada oo leh qiimeynta adag ee Mohs ee 9, waxay bixisaa adkeysi waara iyo iska caabin xoqan.

-

adkeysiga kulaylka- Waxay ilaalisaa daacadnimada qaabdhismeedka ka sarreeya 1600 ° C, oo ka sarreeya birta iyo dhigooda polymer.

-

dahaarka korontada- Waxay baabi'isaa isku-ururinta joogtada ah waxayna bixisaa ilaalin buuxda oo koronto ah.

-

Difaaca kiimikada- Asiidh, alkalis, gaasaska balaasmaha, iyo xalalka nadiifinta ee aan waxyeelayn.

-

Khatar faddarayn aad u hooseeya- Aan gaas baxayn, oogada jaban ee yaraynaysa sii daynta walxaha ee qolalka nadiifka ah.

Sifooyinkani waxay u oggolaanayaan alumina wax-soo-saarka dhammaadka dhoobada inay si cillad la'aan ah ugu shaqeeyaan deegaanno qallafsan oo sax ah.

Codsiyada Muhiimka ah ee Alumina Ceramic End Effector

Kala-duwanaanta gacmaha alumina ceramic end effectorfork waxay ka dhigtaa lama huraan warshado badan oo teknoolojiyad sare ah:

-

Nidaamyada gaadiidka wafer ee Semiconductor- Si badbaado leh ugu dhaqdhaqaajiya mashiinnada silikoon ee geeddi-socod ilaa hab-socodka iyada oo aan lahayn xoqin-yar.

-

Wax soo saarka muraayada fidsan- Qabashada muraayadaha jilicsan ee OLED, LCD, ama mikroLED.

-

Wax-soo-saarka Photovoltaic (PV).- Taageerida rarida waferka qoraxda iyo dejinta wareegyada robotka xawaaraha sare leh.

-

Isku-xidhka qaybaha indhaha iyo elektiroonigga ah- Qabashada qaybaha jilicsan sida dareemayaasha, iska caabinta, iyo chips-yar.

-

Vakuum iyo automation qolka nadiifka ah- Qabashada hawlaha saxda ah ee aadka u nadiifsan, xaaladaha qayb-xakamaynta.

Xaalad kasta, Alumina Ceramic End Effector wuxuu bixiyaa isku xirka muhiimka ah ee ka dhexeeya automation-ka iyo alaabta la raray.

Nakhshadeynta iyo Ikhtiyaarada Isbeddelka ee Alumina Ceramic End Effector

Khad kasta oo wax soo saarku wuxuu leeyahay shuruudo gaar ah. Sidaa darteed, waxaan ku siinaynaa dawaar-sameeyey Alumina Ceramic End Effector xalalka cabbirrada wafer ee kala duwan, nidaamyada robotic, iyo hababka maaraynta:

Waafaqid Wafer: Waxay xakamaysaa waferrada min 2" ilaa 12" waxaana loo miisaami karaa qaybaha gaarka ah.

Ikhtiyaarada joomatari: fargeeto keli ah, fargeeto laba geesood ah, meelo badan, ama qaabab gaar ah oo leh meelo banaan oo isku dhafan.

Xakamaynta faakuumka: kanaalada nuugista faakuumka ee ikhtiyaarka ah ee taageerada waferka aan xidhiidhka lahayn.

Isku-xidhka-kordhinta: godadka boodhka gaarka ah, geesaha, ama nashqado goglan oo ku habboon cudud kasta oo roboti ah.

Dusha sare ayaa dhammaatay: Sagxadaha oo si fiican loo xiiray ama aadka loo dhameeyay (hoos ilaa Ra <0.15 μm).

Muuqaalka cidhifka: geeso la jarjaray ama wareegsan si loo ilaaliyo waferka ugu badan.

Kooxdayada injineernimada Alumina Ceramic End Effector waxay ka shaqeyn karaan sawirada CAD macaamiisha ama qaybaha muunada, hubinta isdhexgalka aan kala go 'lahayn ee nidaamyada otomatiga ah ee jira.

Faa'iidooyinka ugu muhiimsan ee Alumina Ceramic Effectors

| Muuqaal | Maxaa Sabab U Ah |

|---|---|

| Saxnaanta cabbirka | Waxay ilaalisaa toosinta qumman xitaa xawaaraha sare, wareegyada soo noqnoqda. |

| Aan wasakhayn | Waxay soo saartaa gabi ahaanba wax walxo ah, oo daboolaya baahiyaha qolka nadiifka ah ee adag. |

| Cadaadiska kulaylka iyo daxalka | U adkaysta tillaabooyinka habaynta gardarada leh iyo shoogga kulaylka. |

| Wax lacag ah malaha | Waxay ka ilaalisaa waferrada xasaasiga ah iyo qaybaha khatarta korantada. |

| Fudud laakiin adag | Waxay bixisaa qallafsanaan sare iyada oo aan waxyeello loo geysan cududda gacanta ee robotka. |

| Nolosha adeeg ee la dheereeyey | Wuxuu ka sarreeyaa gacmaha birta iyo polymer-ka ee cimriga iyo kalsoonida. |

Isbarbardhigga Waxyaabaha Alumina Ceramic End Effector

| Sifada | Gacanta Fargeeto Caaga ah | Gacan Fargeeto Aluminium/Bir ah | Fargeeto dhoobada alumina |

|---|---|---|---|

| Adag | Hoose | Dhexdhexaad | Aad u Sareeya |

| Heerarka kulaylka | ≤ 150°C | ≤ 500°C | Ilaa 1600°C |

| Deganaanshaha Kiimikada | Miskiin | Dhexdhexaad | Aad u fiican |

| Qiimaynta Qolka Nadiifinta | Hoose | Celcelis ahaan | Ku habboon fasalka 100 ama ka wanaagsan |

| Xiro iska caabin | Xaddidan | Wacan | heer sare ah |

| Heerka cusboonaysiinta | Dhexdhexaad | Xaddidan | Balaadhan |

Su'aalaha Inta badan La Isweydiiyo (FAQ) ee Alumina Ceramic End Effector

Q1: Maxaa ka dhigaya alumina dhamaadka waxtarka dhoobada ka duwan kan birta ah?

A1:Si ka duwan sida aluminium ama gacmaha birta, dhoobada alumina ma daxaleysato, ma beddeleyso, mana soo bandhigto ions macdan hababka semiconductor. Cabbir ahaan waxay ku ahaanaysaa mid deggan marka ay jiraan xaalado aad u daran oo aan soo dayn wax qaybo ah.

Q2: Miyaa kuwan Alumina Ceramic End Effector loo isticmaali karaa qolalka vacuum-sare iyo balaasmaha?

A2:Haa Alumina dhoobada waaaan gaaska lahaynoo adkaysi u leh balaasmaha, taas oo ka dhigaysa shay la door bidayo oo lagu farsameeyo faakuumka iyo qalabka xoqidda.

Q3: Sidee loo beddeli karaa kuwan Alumina Ceramic End Effector fargeeto gacmaha?

A3:Unug kastaa wuu noqon karaasi buuxda loo habeeyey-oo ay ku jiraan qaabka, boosaska, godadka nuugista, qaabka kor u qaadista, iyo dhamaadka cidhifyada - si loo waafajiyo shuruudaha nidaamkaaga robotiga.

S4: Ma jilicsan yihiin?

A4:Iyadoo dhoobada ay leedahay jajab dabiici ah, injineernimada naqshadeena waxay u qaybisaa culeyska si siman waxayna yareysaa dhibcaha walaaca. Marka si sax ah loo maareeyo, nolosha adeeggu inta badan way ka badan tahay tan biraha ama beddelka polymer-ka.

Annaga

XKH waxay ku takhasustay horumarinta tignoolajiyada sare, wax soo saarka, iyo iibinta muraayadaha indhaha ee gaarka ah iyo agabka cusub ee crystal. Badeecadahayadu waxay u adeegaan qalabka elektarooniga ah, elektiroonigga macaamiisha, iyo militariga. Waxaan bixinaa qaybaha indhaha ee Sapphire, daboolka muraayadda taleefanka gacanta, Ceramics, LT, Silicon Carbide SIC, Quartz, iyo maraqyada crystal semiconductor. Iyada oo leh khibrad xirfad leh iyo qalab-goynta, waxaan ku fiicanahay habaynta badeecada aan caadiga ahayn, annagoo higsanayna inaan noqono hormuudka agabka optoelectronic shirkad farsamo sare leh.