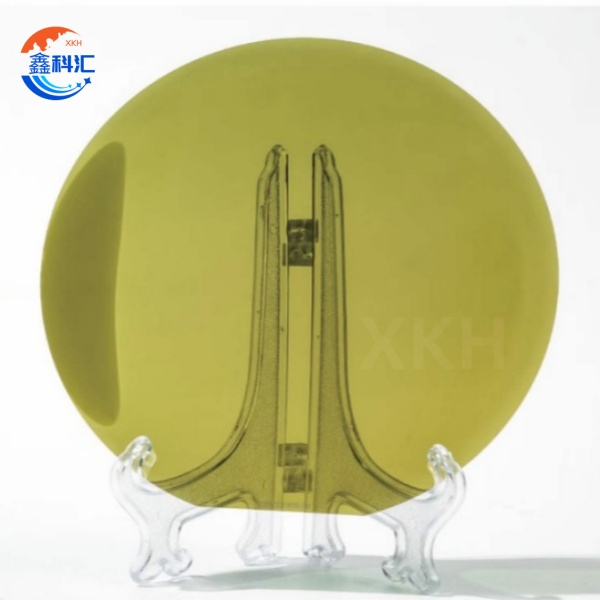

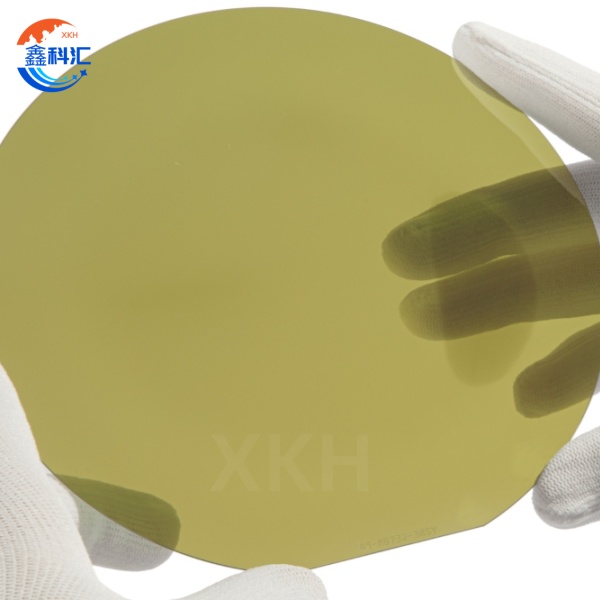

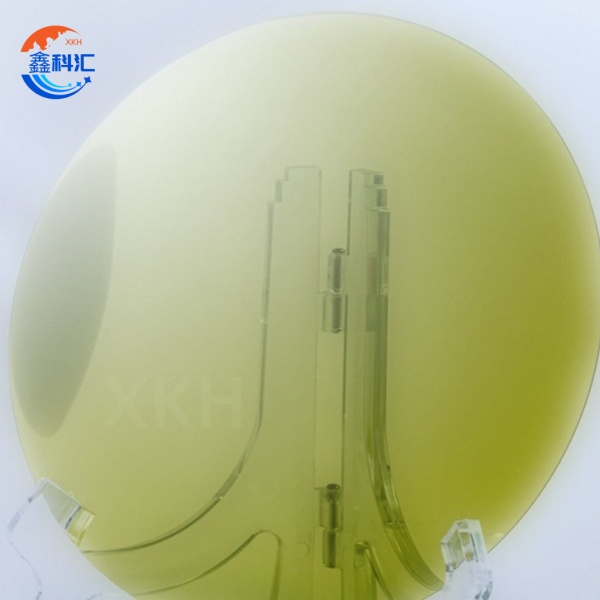

6 Inj Waxqabadka SiC Isku-dhafka Substrate 4H Dhexroorka 150mm Ra≤0.2nm Warp≤35μm

Xuduudaha farsamada

| Walxaha | Wax soo saardarajo | nacasnimodarajo |

| Dhexroorka | 6-8 inji | 6-8 inji |

| Dhumucda | 350/500± 25.0 μm | 350/500± 25.0 μm |

| Noocyo badan | 4H | 4H |

| iska caabin | 0.015-0.025 ohm · cm | 0.015-0.025 ohm · cm |

| TTV | ≤5 μm | ≤20 μm |

| Warp | ≤35 μm | ≤55 μm |

| Hore (Si-wejiga) qallafsanaanta | Ra≤0.2 nm (5μm×5μm) | Ra≤0.2 nm (5μm×5μm) |

Tilmaamaha Muhiimka ah

1.Cost Advantage: Our 6-inch conductive SiC substrate ka kooban shaqaaleeyayaal lahaansho "lakabka buffer darajo" technology oo wanaajinaya ka kooban walxaha si loo yareeyo kharashka alaabta ceeriin by 38% iyada oo la ilaalinayo waxqabadka koronto oo aad u fiican. Qiyaasaha dhabta ah waxay muujinayaan in 650V MOSFET aaladaha isticmaalaya substrate-kan ay gaadhaan 42% hoos u dhac ku yimid qiimaha halkii unug marka la barbar dhigo xalalka caadiga ah, taas oo muhiim u ah kor u qaadida qalabka SiC ee qalabka elektiroonigga ah ee macaamiisha.

2.Excellent Properties Conductive Properties: Iyada oo loo marayo hababka xakamaynta doping nitrogen ee saxda ah, 6-inch substrate-ka isku dhafan ee SiC wuxuu gaaraa iska caabin aad u hooseeya oo ah 0.012-0.022Ω · cm, iyada oo kala duwanaansho lagu xakameynayo ± 5%. Waxa xusid mudan, waxaanu ilaalinayna isku-duubnida iska caabbinta xitaa gudaha 5mm cidhifka wafer-ka, anagoo xalinayna dhibaatada cidhifka ah ee warshadaha.

Performance 3.Thermal: A 1200V / 50A module horumariyo isticmaalaya substrate our muujinaysaa kaliya 45 ℃ heerkulka isgoyska kor u kaca ah ee hawlgalka load buuxa - 65 ℃ ka hooseeya qalabka silikon ku salaysan barbar dhig. Tan waxaa awood u leh "3D channel thermal" qaab dhismeed isku dhafan oo wanaajinaya kulaylka dambe ee 380W/m·K iyo kulaylka toosan ilaa 290W/m·K.

4.Process Compatibility: Qaabdhismeedka gaarka ah ee 6-inch conductive SiC substrates composite substrates, waxaan soo saarnay habka leysarka xatooyada ah ee isku midka ah ee lagu gaaro xawaaraha goynta 200mm / s iyadoo la xakameynayo cirifka cirifka ee ka hooseeya 0.3μm. Intaa waxaa dheer, waxaan bixinaa ikhtiyaarada substrate-ka hore ee nikkel-plated kaasoo awood u siinaya isku xirnaanta dhimashada tooska ah, badbaadinta macaamiisha laba tilaabo oo geeddi-socod ah.

Codsiyada ugu muhiimsan

Qalab Khariidad Wanagsan:

Nidaamyada gudbinta korantada aadka u sarreeya ee tooska ah ee hadda (UHVDC) ee ka shaqeeya ± 800kV, aaladaha IGCT ee isticmaalaya 6-inch substrates-ka isku dhafan ee SiC waxay muujinayaan kor u kaca waxqabadka cajiibka ah. Aaladahani waxay gaadhaan 55% hoos u dhac ku yimaadda beddelka khasaaraha inta lagu jiro hababka isu-socodka, iyada oo la kordhinayo waxtarka nidaamka guud oo uu dhaafo 99.2%. Kuleylka sare ee substrates-ku (380W/m · K) waxa uu awood u siinayaa naqshado beddeleyaal is haysta oo hoos u dhigaya raad-hoosaadka 25% marka la barbar dhigo xalalka silikoon-ku-salaysan ee caadiga ah.

Tareenada Tamarta Cusub ee Baabuurka:

Nidaamka wadista ee ku daraya 6-inch substrates-ka isku dhafan ee SiC wuxuu gaarayaa cufnaanta koronto ee aan horay loo arag ee 45kW/L - 60% horumar ah marka loo eego naqshadoodii hore ee 400V ee silikon ku salaysan. Tan ugu cajiibsan, nidaamku wuxuu ilaaliyaa waxtarka 98% ee dhammaan heerkulka hawlgalka ee u dhexeeya -40 ℃ ilaa +175 ℃, isagoo xalinaya caqabadaha waxqabadka cimilada qabow ee aafeeyay korsashada EV ee cimilada waqooyiga. Tijaabada dhabta ah waxay muujinaysaa korodhka 7.5% ee kala duwanaanshaha jiilaalka ee baabuurta ku qalabaysan farsamadan.

Dareewalada Soo noqnoqoshada Warshadaha ee Kala-duwan:

Qaadashada substrates-yadayada ee modules-yada awoodda caqliga leh (IPMs) ee nidaamyada servo warshadaha ayaa beddelaya automation-ka wax soo saarka. Xarumaha mashiinada CNC, cutubyadani waxay bixiyaan 40% jawaab celinta dhaqdhaqaaqa dhaqsaha badan (yaraynta wakhtiga dardargelinta min 50ms ilaa 30ms) iyadoo la jarayo dhawaaqa korantada ee 15dB ilaa 65dB(A).

Elektrooniga Macmiilka:

Kacaanka macaamiisha elektiroonigga ah wuxuu ku sii socdaa substrate-yadayada awood u siinaya jiilka soo socda ee 65W GaN dabaysha degdega ah. Adabiyeyaashan korantada is haysta waxay gaadhaan 30% hoos u dhigista mugga (hoos u dhaca 45cm³) iyagoo ilaalinaya soo saarista tamarta buuxda, taas oo ay ugu wacan tahay sifooyinka beddelka sare ee naqshadaha ku salaysan SiC. Sawirka kulaylka ayaa muujinaya heerkulka ugu sarreeya ee 68 ° C inta lagu jiro hawlgalka joogtada ah - 22 ° C qabow marka loo eego naqshadaha caadiga ah - si weyn u hagaajinaya nolosha alaabta iyo badbaadada.

Adeegyada Habaynta XKH

XKH waxay siisaa taageero is-beddelid dhamaystiran oo loogu talagalay 6-inch substrates ka kooban SiC:

Habaynta Dhumucda: Ikhtiyaarada ay ku jiraan 200μm, 300μm, iyo 350μm qeexitaannada

2. Xakamaynta iska caabinta: N-nooca doping-ga la hagaajin karo laga bilaabo 1 × 10¹⁸ ilaa 5 × 10¹⁸ cm⁻³

3. Hanuuninta Crystal: Taageerada hanuunin badan oo ay ku jiraan (0001) dhidibka ka baxsan 4° ama 8°

4. Adeegyada Tijaabada: Dhammaystiran warbixinnada tijaabada heerka wafer-ka oo dhamaystiran

Waqtigayaga hogaanka hadda laga bilaabo prototying ilaa wax soo saarka guud wuxuu noqon karaa mid gaaban ilaa 8 toddobaad. Macaamiisha istaraatiijiga ah, waxaan u bixinaa adeegyo horumarineed oo u go'an si loo hubiyo in ay ku habboon yihiin shuruudaha qalabka.