Laga soo bilaabo mabda'a shaqada ee LED-yada, waxay caddaynaysaa in waferka epitaxial uu yahay qaybta asaasiga ah ee LED. Dhab ahaantii, halbeegyada muhiimka ah ee optoelectronic sida hirarka dhererka, dhalaalka, iyo korantada hore waxaa inta badan go'aamiya walxaha epitaxial. Tignoolajiyada waferka Epitaxial iyo qalabku waxay muhiim u yihiin habka wax soo saarka, oo leh Metal-Organic Chemical Vapor Deposition (MOCVD) oo ah habka aasaasiga ah ee koraya lakabyada hal-crystal khafiif ah ee III-V, II-VI xeryahooda, iyo agabkooda. Hoos waxaa ku yaal qaar ka mid ah isbeddellada mustaqbalka ee tignoolajiyada wafer ee LED epitaxial.

1. Hagaajinta Geedi-socodka Kobaca Labo-Tallaabo

Waqtigan xaadirka ah, wax-soo-saarka ganacsigu wuxuu shaqeeyaa geeddi-socod korriin laba-tallaabo ah, laakiin tirada substrate-ka ee hal mar la rari karo waa xaddidan tahay. Iyadoo nidaamyada 6-wafer-ku ay qaan-gaar yihiin, mishiinnada gacanta ku haya ku dhawaad 20 wafer ayaa weli la horumarinayaa. Kordhinta tirada waferrada waxay inta badan keentaa labbis la'aanta lakabyada epitaxial. Horumarrada mustaqbalka waxay diiradda saari doonaan laba jiho:

- Horumarinta tignoolajiyada u oggolaanaysa in lagu shubo substrates badan hal qol oo falcelin ah, taasoo ka dhigaysa inay aad ugu habboon yihiin wax-soo-saarka baaxadda leh iyo dhimista qiimaha.

- Horumarinta si toos ah otomaatig ah, qalabka wafer-kaliya dib loo celin karo.

2. Tignoolajiyada Wajiga Xakamaynta Uumiga Hydride (HVPE).

Tiknoolajiyadani waxay awood u siinaysaa korriinka degdega ah ee filimada qaro weyn oo leh cufnaanta kala-baxa hooseeya, kuwaas oo u adeegi kara sida substrates koritaanka homoepitaxial iyadoo la adeegsanayo habab kale. Intaa waxaa dheer, filimada GaN ee ka soocay substrate-ka ayaa laga yaabaa inay noqdaan beddelka gaN-ga hal-crystal chips. Si kastaba ha ahaatee, HVPE waxay leedahay dib-u-dhacyo, sida inay ku adkaato xakamaynta dhumucda saxda ah iyo gaasas fal-celin daxal ah oo hor-istaagaya horumarinta dheeraadka ah ee nadiifnimada walxaha GaN.

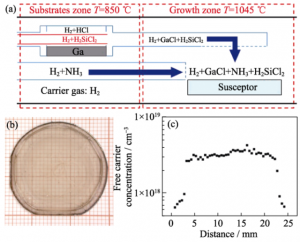

Si-doped HVPE-GAN

(a) Qaab-dhismeedka Si-doped HVPE-GaN reactor; (b) Sawirka 800 μm- dhumucdiisuna waxay tahay Si-doped HVPE-GAN;

(c) Qaybinta uruurinta qaade bilaasha ah oo ay weheliso dhexroorka Si-doped HVPE-GaN

3. Kobaca Epitaxial ee Xulashada ama Tignoolajiyada Kobaca Epitaxial

Farsamadan waxay sii yareyn kartaa cufnaanta kala-baxa waxayna wanaajin kartaa tayada crystal ee lakabyada epitaxial GaN. Nidaamku wuxuu ku lug leeyahay:

- Ku kaydinta lakabka GaN substrate ku habboon (sapphire ama SiC).

- Dhigista lakabka maaskaro ee SiO₂ polycrystalline dusha sare.

- Isticmaalka sawir-qaadista iyo xoqidda si loo abuuro daaqadaha GaN iyo maaskaro SiO₂ ah.Inta lagu jiro korriinka xiga, GaN wuxuu marka hore si toosan uga koraa daaqadaha ka dibna gees ahaan wuxuu uga koraa xariijimaha SiO₂.

Waferka XKH ee GaN-on-Sapphire

4. Pendeo-Epitaxy Technology

Habkani wuxuu si weyn u yareynayaa cilladaha xabagta ee ay sababto isku-dheellitir la'aanta kulaylka ee u dhexeeya lakabka substrate iyo epitaxial, taasoo sii kordhinaysa tayada GaN. Tallaabooyinka waxaa ka mid ah:

- Koritaanka lakabka Epitaxial ee GaN ee substrate ku habboon (6H-SiC ama Si) iyadoo la adeegsanayo hab-raac laba-tallaabo ah.

- Samaynta midabaynta lakabka epitaxial ilaa substrate-ka, abuurista tiir beddelaad ah (GaN/buffer/substrate) iyo dhismayaal godad ah.

- Kordhinta lakabyo GaN oo dheeri ah, kuwaas oo ka sii fidsan darbiyada tiirarka asalka ah ee GaN, oo ka laalaaday godadka.Maadaama aan maaskaro la isticmaalin, tani waxay ka fogaanaysaa xidhiidhka u dhexeeya GaN iyo qalabka maaskaro.

XKH's GaN-on-Silicon wafer

5. Horumarinta Mawjadaha Gaaban ee UV LED Epitaxial Materials

Tani waxay aasaas adag u dhigaysaa LED-yada cad cad ee UV-ku faraxsan fosfor ku salaysan. Fosfoorayaal badan oo wax ku ool ah ayaa ku farxi kara iftiinka UV, iyagoo bixiya waxtarka iftiinka ka sarreeya kan hadda jira ee YAG:Ce, si kor loogu qaado waxqabadka LED-ka cad.

6. Ceelka tirada badan (MQW) Chip Technology

Qaab dhismeedka MQW, wasakhyo kala duwan ayaa lagu daraa inta lagu jiro koritaanka lakabka iftiiminaya si loo abuuro ceelal tiro kala duwan. Dib-u-habaynta photon-yada ka soo baxaya ceelashan ayaa si toos ah u soo saara iftiin cad. Habkani wuxuu wanaajiyaa waxtarka iftiinka, wuxuu yareeyaa kharashyada, wuxuuna fududeeyaa baakadaha iyo xakamaynta wareegga, inkastoo ay soo bandhigto caqabado farsamo oo waaweyn.

7. Horumarinta Farsamada "Dib u warshadaynta Sawirka".

Bishii Janaayo 1999, Sumitomo Japan ayaa soo saartay LED cad oo isticmaalaya walxaha ZnSe. Tiknoolajiyadu waxay ku lug leedahay kobcinta filimka khafiifka ah ee CdZnSe ee ZnSe substrate hal-crystal ah. Marka la koronto, filimku wuxuu soo saaraa iftiin buluug ah, kaas oo la falgala substrate-ka ZnSe si uu u soo saaro iftiin jaale ah oo dhammaystiran, taasoo keentay iftiin cad. Sidoo kale, Xarunta Cilmi-baarista Photonics-ka ee Jaamacadda Boston waxay ku dhejisay isku-xidhka AlInGaP semiconductor-ka buluugga ah ee GaN-LED si ay u dhaliso iftiin cad.

8. Socodka Geedi socodka Wafer Wafer ee LED

① Dhismaha Waferka Epitaxial:

Substrate → Naqshad dhismeed → Kobaca lakabka buffer → N-nooca kobaca lakabka GaN → MQW kobaca lakabka iftiinka-baxa → Nooca P-nooca GaN koritaanka

② Farsamaynta Chip:

Waferka Epitaxial → Naqshadaynta maaskarada iyo samaynta → Photolithography → Ion etching → Nooca E-electrode-ka (dhigista, nuugista, etching) → Nooca P-electrode (dhigid, xoqin, etching) → Dicing → Kormeerka jajabka iyo qiimeynta.

Waferka ZMSH ee GaN-on-SiC

Waqtiga boostada: Jul-25-2025