SiC wafer's abtract

Silikon carbide (SiC) waferswaxay noqdeen substrate-ka doorashada ee tamarta sare, soo noqnoqoshada sare, iyo heerkulka sare ee elektiroonigga ah ee qaybaha baabuurta, tamarta la cusboonaysiin karo, iyo hawada hawada. Bootfooliyadayadu waxay dabooshaa noocyada kala duwan ee muhiimka ah iyo qorshayaasha doping-nitrogen-doped 4H (4H-N), saafi-sare semi-insulating (HPSI), nitrogen-doped 3C (3C-N), iyo p-nooca 4H/6H (4H/6H-P) -oo lagu bixiyo saddex darajo oo tayo leh: PRIME (qalab si buuxda loo sifeeyay, MMY si buuxda loo toosiyay tijaabooyinka habsocodka), iyo CILMI-BAARID (Lakabyada epi-caadiga ah iyo profiles-ka doping ee R&D). Dhexroorrada waferku waxay fidsan yihiin 2″, 4″, 6″, 8″, iyo 12″ si ay ugu habboonaadaan agabka dhaxalka ah iyo dharka sare ee labbada. Waxaan sidoo kale bixinaa boules monocrystalline iyo kiristaalo abuur si sax ah u janjeedha si ay u taageeraan korriinka crystal-ka ee guriga.

Wafersyadayada 4H-N waxay ka kooban yihiin cufnaanta sideyaasha laga bilaabo 1 × 10¹⁶ ilaa 1 × 10¹⁹ cm⁻³ iyo iska caabbinta 0.01-10 Ω·cm, oo keenaya dhaqdhaqaaqa elektaroonigga ah iyo meelaha burbursan ee ka sarreeya 2 MV/cm-ku habboon Schottky diodes, MOSFETs. Substrate-yada HPSI waxay ka badan yihiin 1 × 10¹² Ω·cm iska caabin ah oo leh cufnaanta micropipe ee ka hooseeya 0.1 cm⁻², iyada oo hubinaysa daadinta ugu yar ee qalabka RF iyo microwave. Cubic 3C-N, oo lagu heli karo qaabab 2″ iyo 4″ ah, waxa ay awood u siinaysaa heteroepitaxy silikoon oo waxay taageertaa codsiyada photonic iyo MEMS ee cusub. P-nooca 4H/6H-P wafer, oo lagu shubay aluminium ilaa 1 × 10¹⁶–5 × 10¹⁸ cm⁻³, waxay fududaysaa qaab dhismeedka qalabka dhammaystiran.

Waferka SiC, Waferrada PRIME waxay maraan dhalaalid kiimiko-farsamo ah ilaa <0.2 nm RMS qalafsanaanta dusha sare, wadarta dhumucda kala duwanaanshaha ka hooseeya 3 µm, iyo qaanso <10 µm. Substrate-yada DUMMY waxay dardargeliyaan isu imaatinka iyo tijaabooyinka baakadaha, halka waferrada CILMI-BAARINTA ay muujinayaan dhumucda lakabka epi-lakabka ee 2-30 µm iyo doping bespoke. Dhammaan badeecooyinka waxaa lagu caddeeyey kala-duwanaanshaha raajada (qallooca ruxay <30 arcsec) iyo Raman spectroscopy, oo leh tijaabooyin koronto-cabbirka Hall-ka, C-V profile, iyo iskaanka micropipe-la hubinta u hoggaansanaanta JEDEC iyo SEMI.

Dhismooyinka ilaa 150 mm dhexroorka ah waxaa lagu beeraa PVT iyo CVD oo leh cufnaanta kala-baxa ee ka hooseeya 1 × 10³ cm⁻² iyo tirooyinka micropipe yar. Kiristaalo abuur waxaa lagu gooyay 0.1° dhidibka c-dhidibka si loo dammaanad qaado korriinka la soo saari karo iyo wax soo saarka jeexjeexyada sare.

Marka la isku daro noocyo badan oo kala duwan, kala duwanaansho doping, darajooyin tayo leh, cabbirrada waferka SiC, iyo wax soo saarka gudaha-guriga iyo abuur-crystal, madal substrate-kayaga SiC wuxuu hagaajiyaa silsiladaha sahayda wuxuuna dardargeliyaa horumarinta aaladda baabuurta korantada, xariijimaha smart, iyo codsiyada deegaanka adag.

SiC wafer's abtract

Silikon carbide (SiC) waferswaxay noqdeen substrate-ka SiC ee doorashada awooda sare, soo noqnoqoshada sare, iyo kulaylka sare ee elektiroonigga guud ahaan baabuurta, tamarta la cusboonaysiin karo, iyo qaybaha hawada. Bootfooliyadayadu waxay dabooshaa noocyada kala duwan ee muhiimka ah iyo qorshayaasha doping-nitrogen-doped 4H (4H-N), saafi-sare semi-insulating (HPSI), nitrogen-doped 3C (3C-N), iyo p-nooca 4H/6H (4H/6H-P) -oo lagu bixiyo saddex darajo oo tayo leh: wafer SiCPRIME (si buuxda u dhalaalay, substrates-qalabka), DUMMY (la dubay ama aan la silcin ee tijaabooyinka habraaca), iyo CILMI (Laajooyinka epi-ka caadiga ah iyo profiles-ka doping ee R&D). Dhexroorrada SiC Wafer waxay fidsan yihiin 2″, 4″, 6″, 8″, iyo 12″ si ay ugu habboonaadaan agabka dhaxalka ah iyo dharka sare ee labbada. Waxaan sidoo kale bixinaa boules monocrystalline iyo kiristaalo abuur si sax ah u janjeedha si ay u taageeraan korriinka crystal-ka ee guriga.

Wafersyadayada 4H-N SiC waxay ka kooban yihiin cufnaanta sideyaasha laga bilaabo 1 × 10¹⁶ ilaa 1 × 10¹⁹ cm⁻³ iyo iska caabbinta 0.01-10 Ω·cm, iyagoo keenaya dhaqdhaqaaqa elektaroonigga ah iyo meelaha burbursan ee ka sarreeya 2 MV/cm-ku habboon Schottky diodes, MOSFET. Substrate-yada HPSI waxay ka badan yihiin 1 × 10¹² Ω·cm iska caabin ah oo leh cufnaanta micropipe ee ka hooseeya 0.1 cm⁻², iyada oo hubinaysa daadinta ugu yar ee qalabka RF iyo microwave. Cubic 3C-N, oo lagu heli karo qaabab 2″ iyo 4″ ah, waxa ay awood u siinaysaa heteroepitaxy silikoon oo waxay taageertaa codsiyada photonic iyo MEMS ee cusub. SiC wafer P-nooca 4H/6H-P, oo lagu qurxiyey aluminium ilaa 1 × 10¹⁶–5×10¹⁸ cm⁻³, fududeeya qaab-dhismeedka qalabka kaabayaasha ah.

Waferrada SiC wafer PRIME waxay maraan dhalaal kiimiko-farsamo ah ilaa <0.2 nm RMS qalafsanaanta dusha sare, wadarta dhumucda kala duwanaanshaha ka hooseeya 3 µm, iyo qaanso <10 µm. Substrate-yada DUMMY waxay dardargeliyaan isu imaatinka iyo tijaabooyinka baakadaha, halka waferrada CILMI-BAARINTA ay muujinayaan dhumucda lakabka epi-lakabka ee 2-30 µm iyo doping bespoke. Dhammaan badeecooyinka waxaa lagu caddeeyey kala-duwanaanshaha raajada (qallooca ruxay <30 arcsec) iyo Raman spectroscopy, oo leh tijaabooyin koronto-cabbirka Hall-ka, C-V profile, iyo iskaanka micropipe-la hubinta u hoggaansanaanta JEDEC iyo SEMI.

Dhismooyinka ilaa 150 mm dhexroorka ah waxaa lagu beeraa PVT iyo CVD oo leh cufnaanta kala-baxa ee ka hooseeya 1 × 10³ cm⁻² iyo tirooyinka micropipe yar. Kiristaalo abuur waxaa lagu gooyay 0.1° dhidibka c-dhidibka si loo dammaanad qaado korriinka la soo saari karo iyo wax soo saarka jeexjeexyada sare.

Marka la isku daro noocyo badan oo kala duwan, kala duwanaansho doping, darajooyin tayo leh, cabbirrada waferka SiC, iyo wax soo saarka gudaha-guriga iyo abuur-crystal, madal substrate-kayaga SiC wuxuu hagaajiyaa silsiladaha sahayda wuxuuna dardargeliyaa horumarinta aaladda baabuurta korantada, xariijimaha smart, iyo codsiyada deegaanka adag.

6inch 4H-N nooca xaashida xogta wafer ee SiC

| 6 inch xaashida xogta wafers ee SiC | ||||

| Halbeegga | Sub-parameter | Darajada Z | P Darajada | D Darajada |

| Dhexroorka | 149.5-150.0 mm | 149.5-150.0 mm | 149.5-150.0 mm | |

| Dhumucda | 4H-N | 350 µm ± 15 µm | 350 µm ± 25 µm | 350 µm ± 25 µm |

| Dhumucda | 4H-SI | 500 µm ± 15 µm | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Hanuuninta Wafer | dhidibka ka baxsan: 4.0° dhanka <11-20> ±0.5° (4H-N); Dhinaca dhidibka: <0001> ± 0.5° (4H-SI) | dhidibka ka baxsan: 4.0° dhanka <11-20> ±0.5° (4H-N); Dhinaca dhidibka: <0001> ± 0.5° (4H-SI) | dhidibka ka baxsan: 4.0° dhanka <11-20> ±0.5° (4H-N); Dhinaca dhidibka: <0001> ± 0.5° (4H-SI) | |

| Cufnaanta Dheef-yar | 4H-N | ≤ 0.2cm⁻² | ≤2cm⁻² | ≤15cm⁻² |

| Cufnaanta Dheef-yar | 4H-SI | ≤ 1 cm⁻² | ≤5cm⁻² | ≤15cm⁻² |

| iska caabin | 4H-N | 0.015–0.024 Ω·cm | 0.015–0.028 Ω·cm | 0.015–0.028 Ω·cm |

| iska caabin | 4H-SI | ≥ 1×10¹⁰ Ω·cm | ≥ 1×10⁵ Ω·cm | |

| Hanuuninta Flat Primary | [10-10] ± 5.0° | [10-10] ± 5.0° | [10-10] ± 5.0° | |

| Dhererka Guriga aasaasiga ah | 4H-N | 47.5 mm ± 2.0 mm | ||

| Dhererka Guriga aasaasiga ah | 4H-SI | Darajo | ||

| Ka saarida gees | 3 mm | |||

| Warp/LTV/TTV/Bow | ≤2.5 µm / ≤6 µm / ≤25 µm / ≤35 µm | ≤5 µm / ≤15 µm / ≤40 µm / ≤60 µm | ||

| Qalafsanaan | Polish | Ra ≤ 1 nm | ||

| Qalafsanaan | CMP | Ra ≤ 0.2 nm | Ra ≤ 0.5 nm | |

| Dildilaaca cidhifka | Midna | Dhererka isugeynta ≤ 20 mm, hal ≤ 2 mm | ||

| Hex Plates | Aagga isugeynta ≤ 0.05% | Aagga isugeynta ≤ 0.1% | Aagga isugeynta ≤ 1% | |

| Noocyada kala duwan | Midna | Aagga isugeynta ≤ 3% | Aagga isugeynta ≤ 3% | |

| Kaarboon ku darida | Aagga isugeynta ≤ 0.05% | Aagga isugeynta ≤ 3% | ||

| Xoqashada dusha sare | Midna | Dhererka isugeynta ≤ 1 × dhexroor maroodi | ||

| Chips Edge | Midna lama ogola ≥ 0.2 mm ballac & qoto dheer | Ilaa 7 chips, ≤ 1 mm midkiiba | ||

| TSD ( Kala-baxa Xadhkaha Isku-xidhka ah) | ≤500 cm⁻² | N/A | ||

| BPD (Base Plane Meesha) | ≤ 1000 cm⁻² | N/A | ||

| Wasakhaynta Dusha sare | Midna | |||

| Baakadaha | Cajalad badan oo wafer ah ama weel kaliya oo canjeero ah | Cajalad badan oo wafer ah ama weel kaliya oo canjeero ah | Cajalad badan oo wafer ah ama weel kaliya oo canjeero ah | |

4inch 4H-N nooca xaashida xogta wafer ee SiC

| 4inch xaashida xogta wafer ee SiC | |||

| Halbeegga | Wax soo saarka MPD eber | Heerka Wax-soo-saarka caadiga ah (P Degree) | Fasalka Dhamaystiran (D Derajada) |

| Dhexroorka | 99.5 mm-100.0 mm | ||

| Dhumucda (4H-N) | 350 µm±15 µm | 350 µm±25 µm | |

| Dhumucda (4H-Si) | 500 µm±15 µm | 500 µm±25 µm | |

| Hanuuninta Wafer | dhidibka ka baxsan: 4.0° dhanka <1120> ±0.5° ee 4H-N; Dhinaca dhidibka: <0001> ± 0.5° ee 4H-Si | ||

| Cufnaanta Dheecaan yar (4H-N) | ≤0.2cm⁻² | ≤2cm⁻² | ≤15cm⁻² |

| Cufnaanta Micropipe (4H-Si) | ≤1cm⁻² | ≤5cm⁻² | ≤15cm⁻² |

| Iska caabin (4H-N) | 0.015–0.024 Ω·cm | 0.015–0.028 Ω·cm | |

| Iska caabin (4H-Si) | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |

| Hanuuninta Flat Primary | [10-10] ± 5.0° | ||

| Dhererka Guriga aasaasiga ah | 32.5 mm ± 2.0 mm | ||

| Dhererka Guriga Sare | 18.0 mm ± 2.0 mm | ||

| Hanuuninta Guriga Sare | Silikoon wejiga kor ah: 90° CW laga bilaabo guri dabaq ah ± 5.0° | ||

| Ka saarida gees | 3 mm | ||

| LTV/TTV/Warp qaanso | ≤2.5 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Qalafsanaan | Polish Ra ≤1 nm; CMP Ra ≤0.2 nm | Ra ≤0.5 nm | |

| Dildilaaca Cidhifyada Iftiinka Xoogan Sare | Midna | Midna | Dhererka isugeynta ≤10 mm; dhererka kaliya ≤2 mm |

| Taarikada Hex By Iftiin Xoogan Sare | Aagga wadarta ≤0.05% | Aagga wadarta ≤0.05% | Aagga isugeynta ≤0.1% |

| Meelo Badan Oo Iftiin Xoogan Sare leh | Midna | Aagga isugeynta ≤3% | |

| Kaarboon Muuqaal ah | Aagga wadarta ≤0.05% | Aagga isugeynta ≤3% | |

| Dusha sare ee Silikoon xoqida Iftiinka xoogga sare | Midna | Dhererka isugeynta ≤1 dhexroor maroodi | |

| Chips-ka Cidhifyada Iftiinka Xoogga Sare | Midna lama oggola ≥0.2mm ballac iyo qoto dheer | 5 waa la ogol yahay, ≤1 mm midkiiba | |

| Wasakhaynta Dusha Silikoon ee Iftiinka Xoogan Sare | Midna | ||

| Kala leexashada xadhigga dunta | ≤500 cm⁻² | N/A | |

| Baakadaha | Cajalad badan oo wafer ah ama weel kaliya oo canjeero ah | Cajalad badan oo wafer ah ama weel kaliya oo canjeero ah | Cajalad badan oo wafer ah ama weel kaliya oo canjeero ah |

4inch nooca HPSI xaashida xogta wafer ee SiC

| 4inch nooca HPSI xaashida xogta wafer ee SiC | |||

| Halbeegga | Wax-soo-saarka MPD eber (Grade Z) | Heerka Wax-soo-saarka caadiga ah (P Degree) | Fasalka Dhamaystiran (D Derajada) |

| Dhexroorka | 99.5-100.0 mm | ||

| Dhumucda (4H-Si) | 500 µm ± 20 µm | 500 µm ± 25 µm | |

| Hanuuninta Wafer | dhidibka ka baxsan: 4.0° dhanka <11-20> ±0.5° ee 4H-N; Dhinaca dhidibka: <0001> ± 0.5° ee 4H-Si | ||

| Cufnaanta Micropipe (4H-Si) | ≤1cm⁻² | ≤5cm⁻² | ≤15cm⁻² |

| Iska caabin (4H-Si) | ≥1E9 Ω·cm | ≥1E5 Ω·cm | |

| Hanuuninta Flat Primary | (10-10) ±5.0° | ||

| Dhererka Guriga aasaasiga ah | 32.5 mm ± 2.0 mm | ||

| Dhererka Guriga Sare | 18.0 mm ± 2.0 mm | ||

| Hanuuninta Guriga Sare | Silikoon wejiga kor ah: 90° CW laga bilaabo guri dabaq ah ± 5.0° | ||

| Ka saarida gees | 3 mm | ||

| LTV/TTV/Warp qaanso | ≤3 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| qallafsanaan (C wejiga) | Polish | Ra ≤1 nm | |

| qallafsanaan (Si wejiga) | CMP | Ra ≤0.2 nm | Ra ≤0.5 nm |

| Dildilaaca Cidhifyada Iftiinka Xoogan Sare | Midna | Dhererka isugeynta ≤10 mm; dhererka kaliya ≤2 mm | |

| Taarikada Hex By Iftiin Xoogan Sare | Aagga wadarta ≤0.05% | Aagga wadarta ≤0.05% | Aagga isugeynta ≤0.1% |

| Meelo Badan Oo Iftiin Xoogan Sare leh | Midna | Aagga isugeynta ≤3% | |

| Kaarboon Muuqaal ah | Aagga wadarta ≤0.05% | Aagga isugeynta ≤3% | |

| Dusha sare ee Silikoon xoqida Iftiinka xoogga sare | Midna | Dhererka isugeynta ≤1 dhexroor maroodi | |

| Chips-ka Cidhifyada Iftiinka Xoogga Sare | Midna lama oggola ≥0.2mm ballac iyo qoto dheer | 5 waa la ogol yahay, ≤1 mm midkiiba | |

| Wasakhaynta Dusha Silikoon ee Iftiinka Xoogan Sare | Midna | Midna | |

| Kala-baxa Xadhkaha Isku-xidhka | ≤500 cm⁻² | N/A | |

| Baakadaha | Cajalad badan oo wafer ah ama weel kaliya oo canjeero ah | ||

Codsiga wafer ee SiC

-

Qalabka Korantada ee SiC Wafer ee EV Rovers

MOSFET-yada Wafer-ku-saleysan ee SiC-ga iyo Diodes-ka lagu dhisay substrate-ka wafer-ka ee SiC-ga oo tayadoodu sarreyso waxay keenaan khasaare beddelaad aad u hooseeya. Iyaga oo ka faa'iidaysanaya tignoolajiyada waferka ee SiC, qaybahan korantadu waxay ku shaqeeyaan koronto iyo heerkul sare, taas oo awood u siinaysa rogayaasha wax-ku-oolnimada leh. Isku darka waferka SiC wuxuu u dhintaa heerarka korantada waxay yaraynaysaa shuruudaha qaboojinta iyo raadadka, muujinta kartida buuxda ee hal-abuurka wafer ee SiC. -

Aaladaha RF iyo 5G-sare ee SiC Wafer

Cod-weyneyayaasha RF iyo furayaasha lagu farsameeyay dufcad-hoosaadka SiC wafer waxay muujinayaan kuleyl sare iyo koronto burbursan. Substrate-ka wafer-ka ee SiC waxa uu yareeyaa khasaaraha dielectric ee soo noqnoqda GHz, halka xoogga walxaha SiC wafer uu u ogolaado hawlgal xasiloon oo hoos yimaada awood sare, heerkul sare - samaynta SiC wafer substrate-ka doorashada saldhigyada saldhiga xiga ee 5G iyo nidaamyada radar. -

Qalabka Optoelectronic & LED ee SiC Wafer

Nalalka buluuga ah iyo UV ee ku koray substrate-ka waferka ee SiC waxay ka faa'iideysteen isbarbardhigga dalagyada wanaagsan iyo kala daadinta kulaylka. Isticmaalka wafer-wajiga SiC-da ee nadiifsan waxay hubisaa lakabyada epitaxial lebbiska ah, halka adkaanta dabiiciga ah ee waferka SiC ay awood u siinayso khafiifinta waferka iyo baakadaha aaladda la isku halayn karo. Tani waxay ka dhigeysaa wafer SiC go-to madal loogu talagalay codsiyada LED-ka ee awoodda sare leh, muddada-dheer.

Su'aalaha iyo jawaabaha SiC wafer

1. S: Sidee loo soo saaray waferrada SiC?

J:

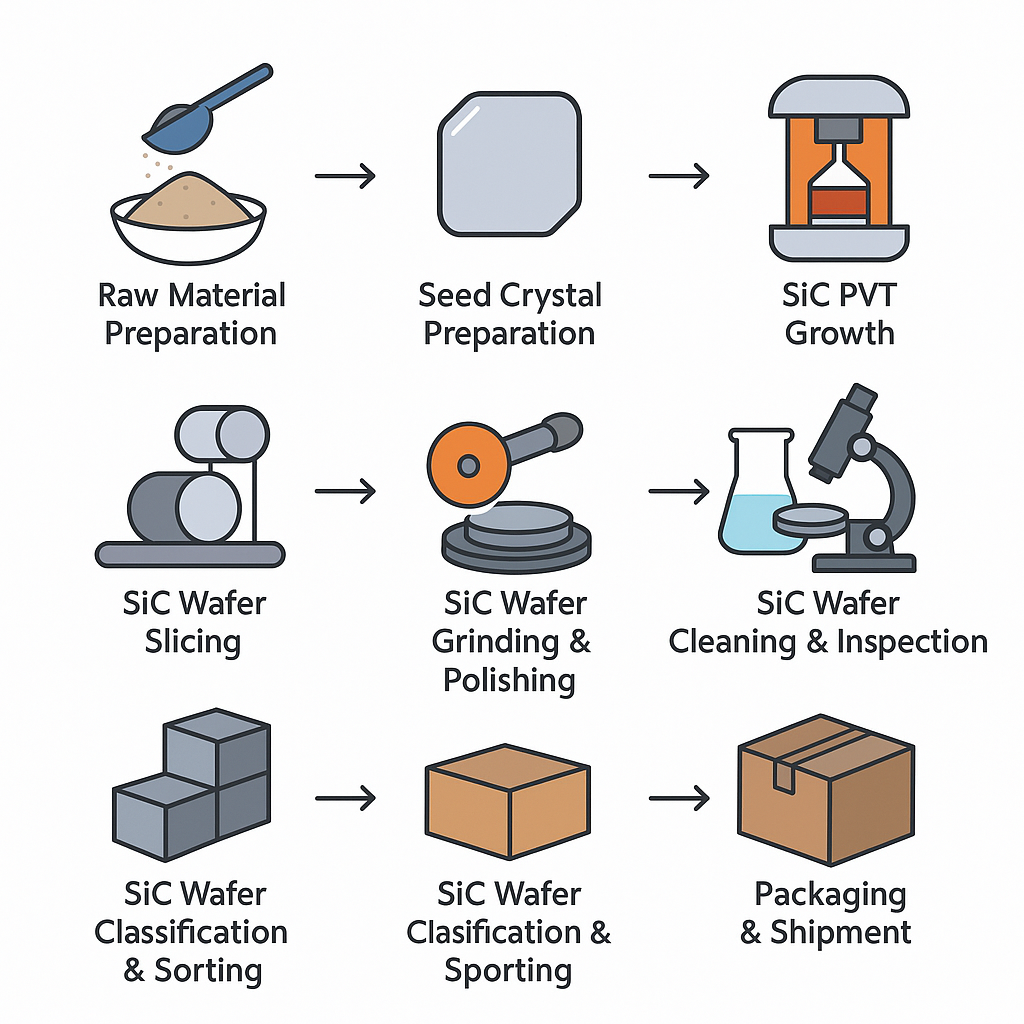

Wafers SiC ayaa la soo saarayTalaabooyinka faahfaahsan

-

SiC wafersDiyaarinta Qalabka Ceyriinka

- Isticmaal budada SiC oo ah ≥5N (wax aan nadiif ahayn ≤1 ppm).

- Sifee oo hore u dub si aad uga saarto kaarboon ama iskudhisyada nitrogen ee haraaga ah.

-

SiCDiyaarinta abuur Crystal

-

Qaado gabal 4H-SiC hal crystal ah, jarjar jihada 〈0001〉 ilaa 10 × 10 mm².

-

Nadiifinta saxda ah ee Ra ≤0.1 nm oo calaamadee jihada crystal.

-

-

SiCKobaca PVT (Gaadiidka Uumiga Jirka)

-

Ku shub graphite crucible: hoose oo leh budada SiC, dusheeda leh crystal abuurka.

-

U bax 10⁻³–10⁻ Torr ama dib ugu buuxi helium daahir sare leh oo ah 1 atm.

-

Aagga isha kulaylka ilaa 2100-2300 ℃, ilaali aagga abuurka 100-150 ℃ qaboojiyaha.

-

Xakamee heerka kobaca 1-5 mm/h si loo dheelitiro tayada iyo wax soo saarka.

-

-

SiCIngot Annealing

-

Bakhtii SiC-ga sida-korray ee 1600-1800 ℃ 4-8 saacadood.

-

Ujeeddo: nafi werwerka kulaylka oo yaree cufnaanta kala-baxa.

-

-

SiCWafer goyn

-

Isticmaal siligga dheemanka ah si aad u jarjartid maraqyada 0.5-1 mm qaro weyn.

-

Yaree gariirka iyo xoogga dambe si aad uga fogaato dildilaaca yaryar.

-

-

SiCWaferShiidida & Tooshka

-

Shiidid aan dhab ahaynsi meesha looga saaro dhaawaca miinshaar (qallafsanaanta ~10-30 µm).

-

Shiidi wanaagsansi loo gaaro fidsanaan ≤5 µm.

-

Kiimiko-Mechanical Polishing (CMP)si loo gaadho dhamaystirka muraayad u eg (Ra ≤0.2 nm).

-

-

SiCWaferNadiifinta & Kormeerka

-

Nadiifinta Ultrasonicxalka Piranha (H₂SO₄: H₂O₂), biyaha DI, ka dibna IPA.

-

XRD/Raman spectroscopysi loo xaqiijiyo nooca badan (4H, 6H, 3C).

-

Interferometrysi loo cabbiro fidsanaanta (<5 µm) iyo fidsan (<20 µm).

-

Baaritaan afar-dhibcood ahsi loo tijaabiyo iska caabbinta (tusaale HPSI ≥10⁹ Ω·cm).

-

Kormeerka cilladaysaniyada oo hoos imanaysa mikroskoobkii iftiinka polarized iyo tijaabiyaha xoqan.

-

-

SiCWaferKala-soocidda & Kala-soocidda

-

U kala sooc maraqyada nooca badan iyo nooca korantada:

-

4H-SiC N-nooca (4H-N): uruurinta side 10¹⁶–10¹⁸ cm⁻³

-

4H-SiC Nadiifinta Sare Semi-Insulating (4H-HPSI): iska caabin ≥10⁹ Ω·cm

-

6H-SiC N-nooca (6H-N)

-

Kuwa kale: 3C-SiC, nooca P, iwm.

-

-

-

SiCWaferBaakadaha & Rarista

2. S: Waa maxay faa'iidooyinka muhiimka ah ee wafers SiC ee ka sarreeya maraqa silikoon?

A: Marka la barbar dhigo waferrada silikoon, waferrada SiC ayaa awood u leh:

-

Hawlgalka tamarta sare(> 1,200 V) oo leh iska caabin hoose.

-

Dejinta heerkulka sare(>300 °C) iyo hagaajinta maareynta kulaylka.

-

Xawaaraha beddelka degdega ahoo leh khasaare beddelaad hoose, yaraynta qaboojinta heerka nidaamka iyo cabbirka beddelayaasha awoodda.

4. S: Waa maxay cilladaha caadiga ah ee saameeya wax-soo-saarka iyo wax-qabadka SiC?

A: Cilladaha aasaasiga ah ee waferrada SiC waxaa ka mid ah micropipes, kala-baxa diyaaradda asalka ah (BPDs), iyo xagashada dusha sare. Tuubbooyinka yaryari waxay sababi karaan cilladda aaladda masiibada; BPDs waxay kordhiyaan iska caabbinta waqti ka dib; iyo xagashada dusha sare waxay u horseedaa jebinta wafer ama korriinka epitaxial oo liita. Kormeer adag iyo yaraynta cilladdu waa lama huraan si loo kordhiyo wax-soosaarka waferka SiC.

Waqtiga boostada: Juun-30-2025