Nadiifinta qoyan (Nadiifinta qoyan) waa mid ka mid ah tillaabooyinka muhiimka ah ee hababka wax soo saarka semiconductor, oo loogu talagalay in laga saaro wasakhaha kala duwan ee dusha sare ee wafer si loo hubiyo in tillaabooyinka xiga ee xiga lagu samayn karo dusha nadiif ah.

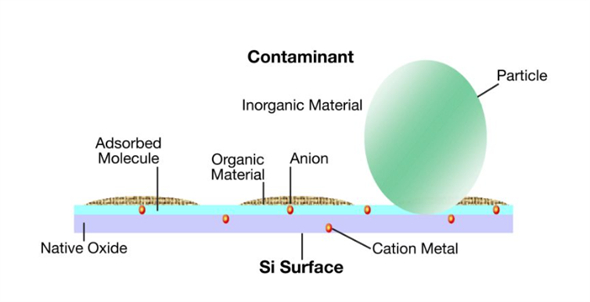

Maaddaama cabbirka aaladaha semiconductor ay sii yaraanayaan oo shuruudaha saxda ah ay kordhayaan, baahida farsamo ee hababka nadiifinta waferka ayaa noqday kuwa sii adag. Xataa qaybaha ugu yar, alaabta organic, aions biraha, ama hadhaaga oksaydhka ee dusha sare ee wafer-ka ayaa si weyn u saameyn kara waxqabadka qalabka, taas oo saameynaysa wax-soo-saarka iyo isku halaynta aaladaha semiconductor.

Mabaadi'da Muhiimka ah ee Nadiifinta Wafer

Xudunta nadiifinta waferka waxay ku jirtaa in si wax ku ool ah looga saaro wasakhaha kala duwan ee dusha sare ee waferka iyada oo loo marayo jireed, kiimiko, iyo habab kale si loo hubiyo in maraqa uu leeyahay dusha nadiif ah oo ku habboon habaynta dambe.

Nooca Wasakhda

Saamaynta ugu weyn ee Astaamaha Aaladda

| maqaal Wasaaq | cilladaha qaabka

Cilladaha ion implantation

Cilladaha burburka filimka dahaarka

| |

| Wasakhowga Birta | Biraha Alkali | MOS transistor xasiloonida

Burburka/hoos u dhaca filimka Gate oxide

|

| Biraha culus | Kordhinta isgoysyada PN ee dareeraha hadda jira

Cilladaha burburka filimka Gate oxide

Sidaha tirada yar hoos u dhaca cimrigiisa

Jiilka cilladda lakabka kicinta oksaydhka

| |

| Wasakhaynta Kiimikada | Walxaha dabiiciga ah | Cilladaha burburka filimka Gate oxide

Kala duwanaanshaha filimka CVD (wakhtiyada soo-jiidashada)

Kala duwanaanshaha dhumucda filimka oksaydh-kuleylka (oksaydheynta degdega ah)

Dhaca cuncun (wafer, muraayad, muraayad, maaskaro, indho-beel)

|

| Dopants Aan Organic (B, P) | MOS transistor Vth ayaa isbedelaya

Si substrate iyo caabbinta sare ee xaashida poly-silicon kala duwanaanshaha

| |

| Saldhigyada aan noolaha ahayn (amines, ammonia) & acids (SOx) | Hoos-u-dhac ku yimaadda xallinta caabbinta kiimiko ahaan la xoojiyay

Dhacda wasakhowga walxaha iyo cirridka ay sabab u tahay abuurista milixda

| |

| Filimada Oksijiinta Dhaladka iyo Kiimikada ah ee ay ugu wacan tahay Qoyaanka, Hawada | Iska caabinta xidhiidhka oo kordhay

Burburka/hoos u dhaca filimka Gate oxide

| |

Gaar ahaan, ujeedooyinka habka nadiifinta waferka waxaa ka mid ah:

Ka Saaridda Qaybaha: Isticmaalka hababka jirka ama kiimikaad si aad uga saarto walxaha yaryar ee ku dheggan dusha waferka. Qaybaha yaryar ayaa aad u adag in la saaro sababtoo ah xoogag elektrostatic ah oo xooggan oo u dhexeeya iyaga iyo dusha sare ee wafer, oo u baahan daaweyn gaar ah.

Ka Saaridda Walxaha Dabiiciga ah: Wasakhowga dabiiciga ah sida dufanka iyo haraaga sawir-qaadista ayaa laga yaabaa inay ku dhegganaadaan dusha sare ee waferka. Wasakhooyinkan waxaa sida caadiga ah la saaraa iyadoo la isticmaalayo walxo oksaydhiye ah oo xooggan ama dareerayaal.

Ka Saaridda Birta Ion: Hadhaaga ion birta ee dusha sare ee wafer-ka waxay hoos u dhigi kartaa waxqabadka korantada oo xitaa saameyn ku yeelan karta talaabooyinka habaynta ee xiga. Sidaa darteed, xalal kiimiko ah oo gaar ah ayaa loo isticmaalaa in laga saaro ion kuwan.

Ka Saaridda oksaydhka: Nidaamyada qaar waxay u baahan yihiin in dusha sare ee waferku ay ka xoroobaan lakabyada oksaydhka, sida silicon oxide. Xaaladahan oo kale, lakabyada oxide dabiiciga ah waxay u baahan yihiin in la saaro inta lagu jiro tallaabooyinka nadiifinta qaarkood.

Caqabadda tignoolajiyada nadiifinta waferka waxay ku jirtaa in si hufan loo saaro wasakhda iyada oo aan si xun u saamaynayn dusha sare ee wafer, sida ka hortagga qallafsanaanta dusha sare, daxalka, ama dhaawaca kale ee jirka.

2. Socodka Nadiifinta Wafer

Habka nadiifinta waferku wuxuu caadi ahaan ku lug leeyahay tillaabooyin badan si loo hubiyo in si buuxda looga saaro wasakhda loona gaaro meel nadiif ah oo nadiif ah.

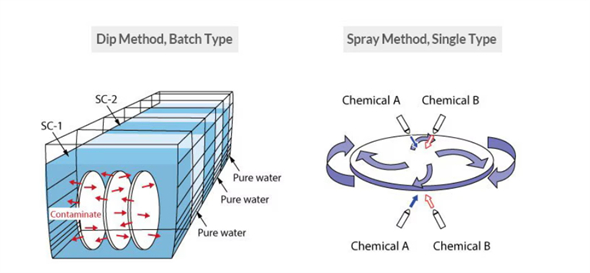

Jaantuska: Isbarbardhigga u dhexeeya Nooca Dufcada iyo Nadiifinta Wafer-kaliya

Habka caadiga ah ee nadiifinta waferka waxaa ka mid ah tallaabooyinka ugu muhiimsan ee soo socda:

1. Nadiifinta ka hor (Hore-nadiifin)

Ujeedada nadiifinta hore waa in laga saaro wasakhowga dabacsan iyo qaybo waaweyn oo ka soo baxa dusha sare ee wafer, kaas oo sida caadiga ah lagu gaaro biyaha deionized (DI Water) luqluqashada iyo nadiifinta ultrasonic. Biyaha deionized ayaa marka hore ka saari kara walxaha iyo wasakhda milmay ee dusha sare ee waferka, halka nadiifinta ultrasonic ay isticmaasho saamaynta cavitation si ay u jebiso xidhiidhka ka dhexeeya qaybaha iyo dusha sare ee wafer, taasoo ka dhigaysa inay sahlanaato in la daadiyo.

2. Nadiifinta Kiimikada

Nadiifinta kiimikadu waa mid ka mid ah tillaabooyinka asaasiga ah ee habka nadiifinta waferka, iyadoo la isticmaalayo xalalka kiimikaad si looga saaro walxaha organic, aions biraha, iyo oksaydhyada oogada waferka.

Ka Saaridda Walxaha Dabiiciga ah: Caadi ahaan, acetone ama isku dar ah ammonia/peroxide (SC-1) ayaa loo isticmaalaa in lagu milo oo laga soo saaro wasakhda dabiiciga ah. Saamiga caadiga ah ee xalka SC-1 waa NH₄OH

₂O₂

₂O = 1:1:5, oo leh heer kul shaqo oo ku dhow 20°C.

Kasaarida Birta Ion: Nitric acid ama hydrochloric acid/peroxide isku darka (SC-2) ayaa loo isticmaalaa in laga saaro ayoonooyinka birta ee dusha sare ee waferka. Saamiga caadiga ah ee xalka SC-2 waa HCl

₂O₂

₂O = 1:1:6, iyadoo heerkulka lagu ilaalinayo qiyaastii 80°C.

Ka Saaridda Okssaydhka: Nidaamyada qaar, ka saarista lakabka oksaydhka asalka ah ee dusha sare ee wafer ayaa loo baahan yahay, kaas oo loo isticmaalo xalalka hydrofluoric (HF). Saamiga caadiga ah ee xalka HF waa HF

₂O = 1:50, waxaana lagu isticmaali karaa heerkulka qolka.

3. Nadiifinta ugu dambeysa

Nadiifinta kiimikaad ka dib, waferrada sida caadiga ah waxay maraan tillaabada nadiifinta ee u dambaysa si loo hubiyo in aan hadhaaga kiimikaad ku hadhayn dusha sare. Nadiifinta kama dambaysta ahi waxay badiyaa u isticmaashaa biyaha deionized si ay si fiican ugu luqto. Intaa waxaa dheer, nadiifinta biyaha ozone (O₃/H₂O) ayaa loo isticmaalaa si looga saaro wixii wasakhaysan ee haray oogada waferka.

4. Qalajinta

Xabbadaha la nadiifiyey waa in si degdeg ah loo qalajiyo si looga hortago calaamadaha biyoodka ama dib ugu dhejinta wasakhooyinka. Habka qalajinta caadiga ah waxaa ka mid ah qalajinta lafdhabarta iyo nadiifinta nitrogen. Midka hore wuxuu ka saaraa qoyaanka dusha sare ee waferka isagoo ku wareegaya xawaare sare, halka kan dambe uu hubinayo qalajinta dhammaystiran isagoo ku afuufaya gaasta nitrogen ee engegan ee dusha waferka.

wasakhaysan

Habka Nadiifinta Magaca

Sharaxaada Isku-dhafka Kiimikada

Kiimikada

| Qaybaha | Piranha (SPM) | Sulfuric acid/hydrogen peroxide/DI biyo | H2SO4/H2O2/H2O 3-4:1; 90°C |

| SC-1 (APM) | Ammonium hydroxide/hydrogen peroxide/DI biyo | NH4OH/H2O2/H2O 1:4:20; 80°C | |

| Biraha (maaha naxaas) | SC-2 (HPM) | Hydrochloric acid/hydrogen peroxide/DI biyo | HCl/H2O2/H2O1:1:6; 85°C |

| Piranha (SPM) | Sulfuric acid/hydrogen peroxide/DI biyo | H2SO4/H2O2/H2O3-4:1; 90°C | |

| DHF | Kala saar hydrofluoric acid/Biyaha DI (ma saarayo naxaasta) | HF/H2O1:50 | |

| Organics | Piranha (SPM) | Sulfuric acid/hydrogen peroxide/DI biyo | H2SO4/H2O2/H2O 3-4:1; 90°C |

| SC-1 (APM) | Ammonium hydroxide/hydrogen peroxide/DI biyo | NH4OH/H2O2/H2O 1:4:20; 80°C | |

| DIO3 | Ozone oo ku jira biyaha ionized | Isku-dhafka O3/H2O La Hagaajiyay | |

| Oksaydh asal ah | DHF | Kala bixi hydrofluoric acid/DI biyaha | HF/H2O 1:100 |

| BHF | Hydrofluoric acid buffered | NH4F/HF/H2O |

3. Hababka Nadiifinta Waferka Caadiga ah

1. Habka Nadiifinta RCA

Habka nadiifinta RCA waa mid ka mid ah farsamooyinka nadiifinta wafer-ka caadiga ah ee warshadaha semiconductor, oo ay samaysay RCA Corporation 40 sano ka hor. Habkan waxaa ugu horrayn loo adeegsadaa in meesha laga saaro wasakhowga organic iyo birta ion wasakh ah waxaana lagu dhamayn karaa laba tallaabo: SC-1 (Standard Clean 1) iyo SC-2 (Standard Clean 2).

Nadiifinta SC-1: Tallaabadan waxaa inta badan loo isticmaalaa in lagu tirtiro wasakhowga dabiiciga ah iyo walxaha. Xalku waa isku dhafka ammonia, hydrogen peroxide, iyo biyo, kaas oo sameeya lakab khafiif ah oo silikoon oksaydh ah oogada waferka.

Nadiifinta SC-2: Tallaabadan waxaa ugu horrayn loo adeegsadaa in laga saaro wasakhowga birta ah, iyadoo la isticmaalayo isku-dar ah hydrochloric acid, hydrogen peroxide, iyo biyo. Waxay ka tagtaa lakab khafiif ah oo khafiif ah oo ku yaal dusha sare ee wafer si looga hortago dib-u-kicinta.

2. Habka Nadiifinta Piranha (Piranha Etch Clean)

Habka nadiifinta Piranha waa farsamo wax ku ool ah oo aad waxtar u leh oo lagu saaro walxaha dabiiciga ah, iyada oo la adeegsanayo isku dhafka sulfuric acid iyo hydrogen peroxide, sida caadiga ah saamiga 3: 1 ama 4: 1. Sababtoo ah sifooyinka oksaydhka ee aadka u xoogan ee xalkan, waxay ka saari kartaa qadar badan oo ah walxaha organic iyo wasakhda adag. Habkani wuxuu u baahan yahay in si adag loo xakameeyo xaaladaha, gaar ahaan marka la eego heerkulka iyo xoogga saarista, si looga fogaado waxyeello u geysata maraqa.

Nadiifinta ultrasonic waxay isticmaashaa saamaynta cavitation ee ay dhaliso hirarka dhawaaqa badan ee dareeraha ah si looga saaro wasakhda dusha sare ee waferka. Marka la barbar dhigo nadiifinta ultrasonic ee dhaqameed, nadiifinta megasonic waxay u shaqeysaa si isdaba joog ah, taas oo awood u siinaysa ka saarista si hufan oo qaybo yar-yar iyada oo aan waxyeello u geysan dusha sare ee waferka.

4. Nadiifinta Ozone

Tignoolajiyada nadiifinta Ozone waxay ka faa'iidaysataa sifooyinka oksaydhaynta xooggan ee ozone si ay u qudhunto ugana saarto wasakhowga dabiiciga ah dusha sare ee wafer, ugu dambayntana u beddela kaarboon laba ogsaydh iyo biyo aan waxyeello lahayn. Habkani uma baahna isticmaalka reagents kiimikaad qaali ah oo wuxuu keenaa wasakh yar oo deegaanka ah, taasoo ka dhigaysa tignoolajiyada soo ifbaxaysa ee nadiifinta waferka.

4. Qalabka Habka Nadiifinta Wafer

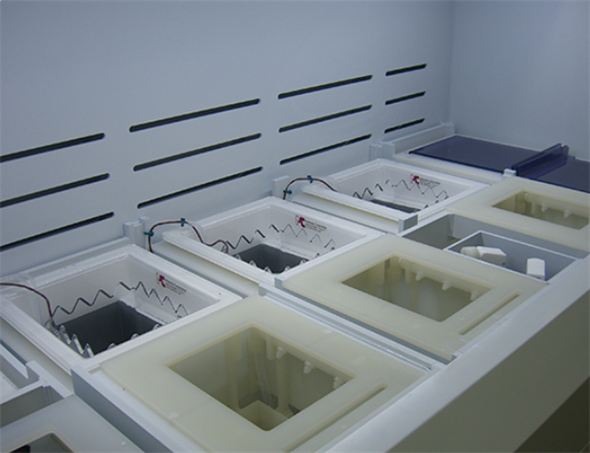

Si loo hubiyo waxtarka iyo badbaadada hababka nadiifinta wafer-ka, noocyo kala duwan oo qalab nadiifin ah oo horumarsan ayaa loo isticmaalaa wax soo saarka semiconductor. Noocyada ugu waaweyn waxaa ka mid ah:

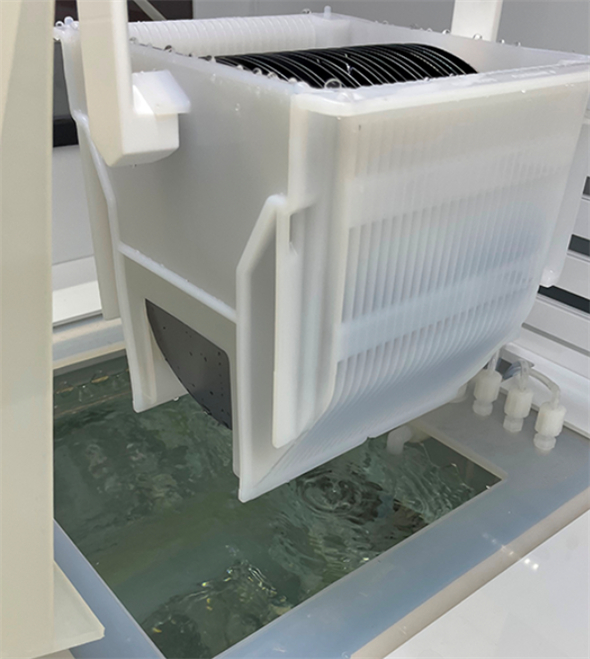

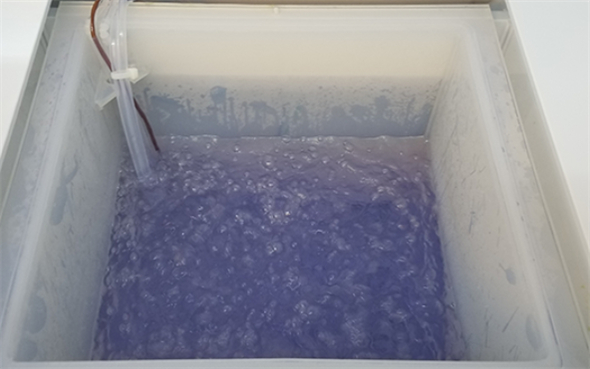

1. Qalabka Nadiifinta qoyan

Qalabka nadiifinta qoyan waxaa ka mid ah taangiyo quusin oo kala duwan, taangiyada nadiifinta ultrasonic, iyo qalajiyaasha lafdhabarta. Qalabkani waxa ay isku daraan xoogaga farsamaysan iyo reagents kiimikaad si ay wasakhda uga saaraan dusha sare ee waferka. Taangiyada Immersion waxaa sida caadiga ah lagu qalabeeyaa hababka xakamaynta heerkulka si loo hubiyo xasiloonida iyo waxtarka xalalka kiimikada.

2. Qalabka Nadiifinta Qalalan

Qalabka nadiifinta qallalan inta badan waxaa ku jira nadiifiyeyaasha balaasmaha, kuwaas oo isticmaala walxaha tamarta sare leh ee balaasmaha si ay uga falceliyaan ugana saaraan hadhaaga dusha waferka. Nadiifinta balaasmadu waxay si gaar ah ugu habboon tahay hababka u baahan ilaalinta sharafta dusha sare iyada oo aan la soo bandhigin hadhaaga kiimikaad.

3. Nidaamyada Nadiifinta Atoomaatiga ah

Iyada oo balaadhinta joogtada ah ee wax-soo-saarka semiconductor, nidaamyada nadiifinta otomaatiga ah ayaa noqday doorashada la doorbido ee nadiifinta wafer-weyn. Nidaamyadani waxay inta badan ku jiraan hababka wareejinta tooska ah, nidaamyada nadiifinta taangiyada badan, iyo hababka xakamaynta saxda ah si loo hubiyo natiijooyinka nadiifinta joogtada ah ee wafer kasta.

5. Isbeddellada Mustaqbalka

Maaddaama aaladaha semiconductor ay sii wadaan inay sii yaraanayaan, tignoolajiyada nadiifinta wafer-ka ayaa u kordheysa xagga xalal wax ku ool ah oo deegaan ahaan u wanaagsan. Tignoolajiyada nadaafadda mustaqbalka waxay diiradda saari doontaa:

Ka saarida Qayb-nanometer-hoosaadka: Tignoolajiyada nadiifinta ee jira waxay xamili karaan walxaha nanometer-ka ah, laakiin hoos u dhaca cabbirka aaladda, ka saarista qaybaha nanometer-hoosaadka waxay noqon doontaa caqabad cusub.

Nadiifinta Cagaaran iyo Deegaanka: Yaraynta isticmaalka kiimikooyinka deegaanka waxyeelada leh iyo horumarinta habab nadiifin oo saaxiibtinimo leh, sida nadiifinta ozone iyo nadiifinta megasonic, waxay noqon doontaa mid sii kordheysa oo muhiim ah.

Heerarka Sare ee Automation-ka iyo Sirdoonka: Nidaamyada caqli-galku waxay awood u siin doonaan la-socodka waqtiga-dhabta ah iyo hagaajinta qiyaasaha kala duwan inta lagu jiro habka nadiifinta, sii wanaajinta waxtarka nadiifinta iyo waxtarka wax soo saarka.

Tiknoolajiyada nadiifinta wafer, oo ah tallaabo muhiim ah oo soo saarista semiconductor, waxay door muhiim ah ka ciyaartaa hubinta sagxadaha wafer ee nadiifka ah ee hababka xiga. Isku dhafka hababka nadiifinta ee kala duwan ayaa si wax ku ool ah u saaraya wasakhda, bixinta dusha sare ee nadiifka ah ee tallaabooyinka xiga. Marka ay tignoolajiyadu horumarto, geeddi-socodka nadiifinta ayaa sii wadi doona in la hagaajiyo si loo daboolo baahida saxnaanta sare iyo heerka cilladda hoose ee wax soo saarka semiconductor.

Waqtiga boostada: Oct-08-2024