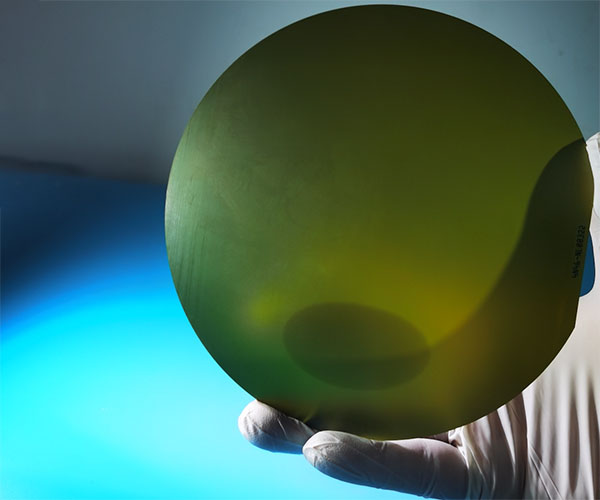

Waqtigan xaadirka ah, shirkadeena waxay sii wadi kartaa inay bixiso dufcad yar oo 8inchN nooca SiC wafers, haddii aad qabto baahi muunad, fadlan xor u noqo inaad ila soo xidhiidho. Waxaan haynaa muunado yar yar oo muunad ah oo diyaar u ah in la raro.

Dhinaca agabka semiconductor, shirkaddu waxay horumar weyn ka samaysay cilmi-baarista iyo horumarinta cabbirka weyn ee SiC crystals. Iyada oo la isticmaalayo kiristaalo abuur u gaar ah ka dib markii wareegyo badan oo ballaadhin dhexroor dhexroor, shirkaddu waxay si guul leh u koray 8-inch N-nooca SiC crystals, kaas oo xalliya dhibaatooyinka adag sida garoonka heerkulka aan sinnayn, crystal dildilaaca iyo qaybinta wajiga gaaska alaabta ceeriin ee geeddi-socodka koritaanka ee 8-inch SIC crystals, iyo dardar-koritaanka of size waaweyn ee kiristaalo SIC iyo tignoolajiyada iskeed u maamuli karo. Si weyn u wanaajiso tartanka xudunta u ah shirkadda ee warshadaha Substrate-ka-kaliya ee SiC. Isla mar ahaantaana, shirkadda si firfircoon kor u raasamaal ee technology iyo habka of size waaweyn silicon carbide substrate diyaarinta line tijaabo ah, xoojisaa is-dhaafsiga farsamada iyo iskaashiga warshadaha ee kor iyo hoos beeraha, iyo iskaashi la macaamiisha si joogto ah u soo saarka wax soo saarka, iyo si wadajir ah kor u xawaaraha codsiga warshadaha ee qalabka carbide silicon.

| 8inch N-nooca SiC DSP Specs | |||||

| Lambarka | Shayga | Unug | Wax soo saar | Cilmi baaris | nacasnimo |

| 1. Halbeegyada | |||||

| 1.1 | nooca badan | -- | 4H | 4H | 4H |

| 1.2 | jihaynta dusha sare | ° | <11-20>4±0.5 | <11-20>4±0.5 | <11-20>4±0.5 |

| 2. Qalabka korantada | |||||

| 2.1 | dopanant | -- | n-nooca Nitrogen | n-nooca Nitrogen | n-nooca Nitrogen |

| 2.2 | iska caabin | ah ·cm | 0.015-0.025 | 0.01-0.03 | NA |

| 3. Mechanical parameter | |||||

| 3.1 | dhexroorka | mm | 200±0.2 | 200±0.2 | 200±0.2 |

| 3.2 | dhumucdiisuna | μm | 500± 25 | 500± 25 | 500± 25 |

| 3.3 | Hanuuninta darajada | ° | [1- 100]±5 | [1- 100]±5 | [1- 100]±5 |

| 3.4 | Qoto dheer | mm | 1 ~ 1.5 | 1 ~ 1.5 | 1 ~ 1.5 |

| 3.5 | LTV | μm | ≤5(10mm*10mm) | ≤5(10mm*10mm) | ≤10 (10mm*10mm) |

| 3.6 | TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Qaansada | μm | -25 ~ 25 | -45-45 | -65-65 |

| 3.8 | Warp | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | AFM | nm | Ra≤0.2 | Ra≤0.2 | Ra≤0.2 |

| 4. qaab dhismeed | |||||

| 4.1 | cufnaanta micropipe | ee/cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | maadada birta ah | atamka/cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | ee/cm2 | ≤500 | ≤1000 | NA |

| 4.4 | BPD | ee/cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | TED | ee/cm2 | ≤7000 | ≤10000 | NA |

| 5. Tayo wanaagsan | |||||

| 5.1 | hore | -- | Si | Si | Si |

| 5.2 | dusha sare dhammayn | -- | Si-wejiga CMP | Si-wejiga CMP | Si-wejiga CMP |

| 5.3 | qayb | ea/wafer | ≤100 (xajmiga≥0.3μm) | NA | NA |

| 5.4 | xoqin | ea/wafer | ≤5, Wadarta Dhererka≤200mm | NA | NA |

| 5.5 | Cidhif chips/indents/ dildilaaca/ wasakhowga | -- | Midna | Midna | NA |

| 5.6 | Aagagga nooca badan | -- | Midna | Aagga ≤10% | Aagga ≤30% |

| 5.7 | calaamadaynta hore | -- | Midna | Midna | Midna |

| 6. Tayada dhabarka | |||||

| 6.1 | dib u dhammayn | -- | C-waji xildhibaan | C-waji xildhibaan | C-waji xildhibaan |

| 6.2 | xoqin | mm | NA | NA | NA |

| 6.3 | Cilladaha dhabarka gees chips/indents | -- | Midna | Midna | NA |

| 6.4 | Dhabar xumada | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Calaamadaynta dhabarka | -- | Darajo | Darajo | Darajo |

| 7. gees | |||||

| 7.1 | gees | -- | Chamfer | Chamfer | Chamfer |

| 8. Xidhmada | |||||

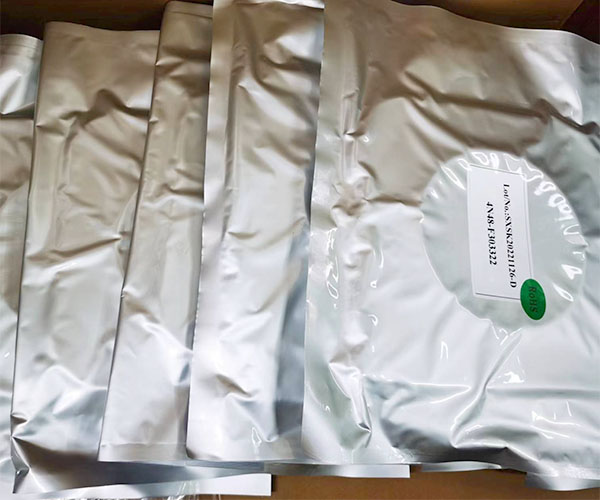

| 8.1 | baakad | -- | Epi- diyaar u ah faakuum baakad | Epi- diyaar u ah faakuum baakad | Epi- diyaar u ah faakuum baakad |

| 8.2 | baakad | -- | Multi-wafer baakad cajalad | Multi-wafer baakad cajalad | Multi-wafer baakad cajalad |

Waqtiga boostada: Abriil-18-2023